Method for reducing earing ratio of deep-drawn part

A technology of deep parts and all directions, applied in the field of deep drawing parts stamping, to improve the anti-wrinkle ability, reduce the ear-making rate, and achieve the effects of uniform deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

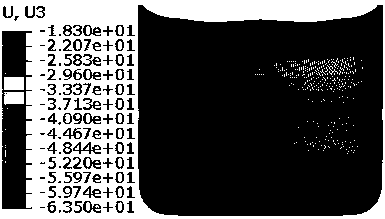

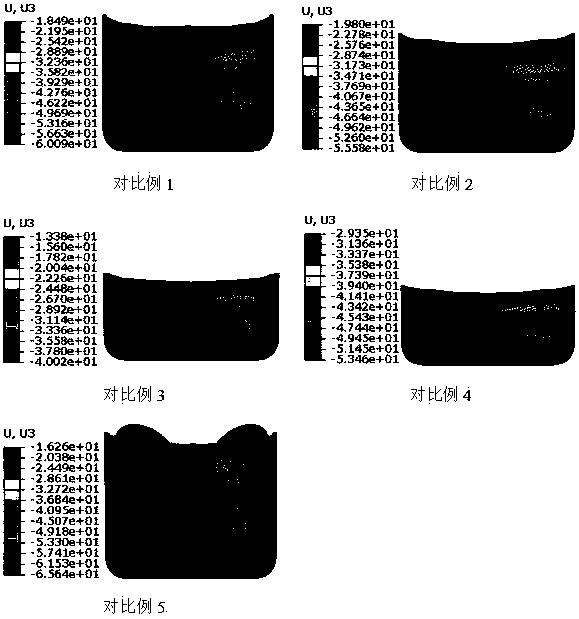

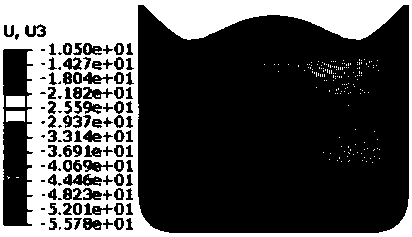

[0026] A method to reduce the lug rate of deep-drawing parts is to configure sections with different tapers in different directions of the blank holder, specifically, to configure large tapers in the direction of low lug height or small plastic strain ratio of the deep-drawing parts. A small taper is arranged in the direction of the high lug height of the drawn part or the direction of the large plastic strain ratio, so that the blank in the direction of the small deformation during the deep drawing process will have a large deformation and a large deformation during the blanking process The blanks in the direction produce small deformation during the blank-holding process, so that the deformation of the blanks in all directions tends to be uniform during the entire drawing process, effectively reducing the lug.

[0027] Below the die that is provided with above-mentioned blank holder ring is referred to as variable taper die (such as figure 1 shown), the blankholder is a vari...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com