Rolling and crushing device for producing environment-friendly bricks

A crushing device and a technology of environmental protection bricks, which are applied to mixers with rotating stirring devices, transportation, packaging, and dissolution, etc., can solve the problems of lower qualified rate of environmentally friendly bricks, improve the efficiency of rolling and crushing, increase the qualified rate of production, The effect of increasing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

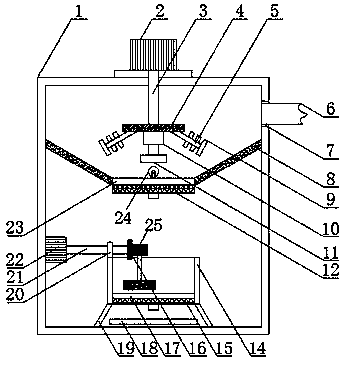

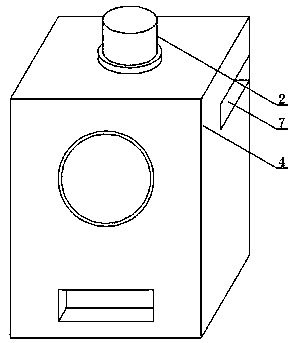

[0029] A rolling crushing device for producing environmentally friendly bricks, such as Figure 1-3 As shown, it includes a box body 1, the top of the outer wall of the box body 1 is installed with a mounting seat through bolts, the outer wall of the top end of the mounting seat is installed with a first motor 2 through bolts, and the bottom end of the first motor 2 is connected to the first rotating shaft 3 through a coupling. , the first rotating shaft 3 runs through the mounting seat and the box body 1 and extends to the inside of the box body 1, the bottom end of the first rotating shaft 3 is welded with a mounting plate 4, and the middle of the bottom end of the mounting plate 4 is installed with a first telescopic rod 10 through bolts, the first The bottom end of the telescopic rod 10 is welded with a pressure block 11, and the two sides of the bottom end of the installation plate 4 are installed with connecting rods 5 through bolts. The outer wall of the connecting rod 5...

Embodiment 2

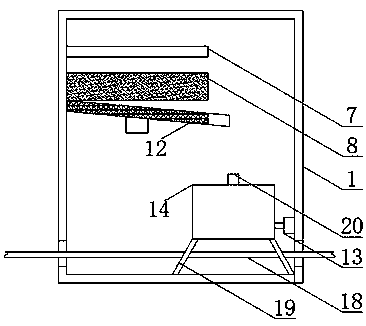

[0033] A rolling crushing device for producing environmentally friendly bricks, such as Figure 4 Shown; The connecting rod 5 and the crushing blade 9 installed on both sides of the bottom end of the mounting plate 4 are replaced with the first telescopic rod 10 and the briquetting block 11.

[0034] When the present embodiment is in use, the connecting rod 5 and the crushing blade 9 are replaced with the first telescopic rod 10 and the briquetting block 11, the number of the first telescopic rod 10 and the briquetting block 11 is increased, the crushing efficiency of the device is improved, and With the high-speed rotation of the first rotating shaft 3, the raw materials can be stirred and mixed, and the filtering speed of the raw materials can be increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com