Raw material hot-melting device for plastic toy production

A plastic toy and hot-melt device technology, which is applied in the direction of grain processing, etc., can solve the problems of affecting processing quality, material burnt, low efficiency, etc., and achieve the effect of improving hot-melting efficiency, avoiding uneven heating, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

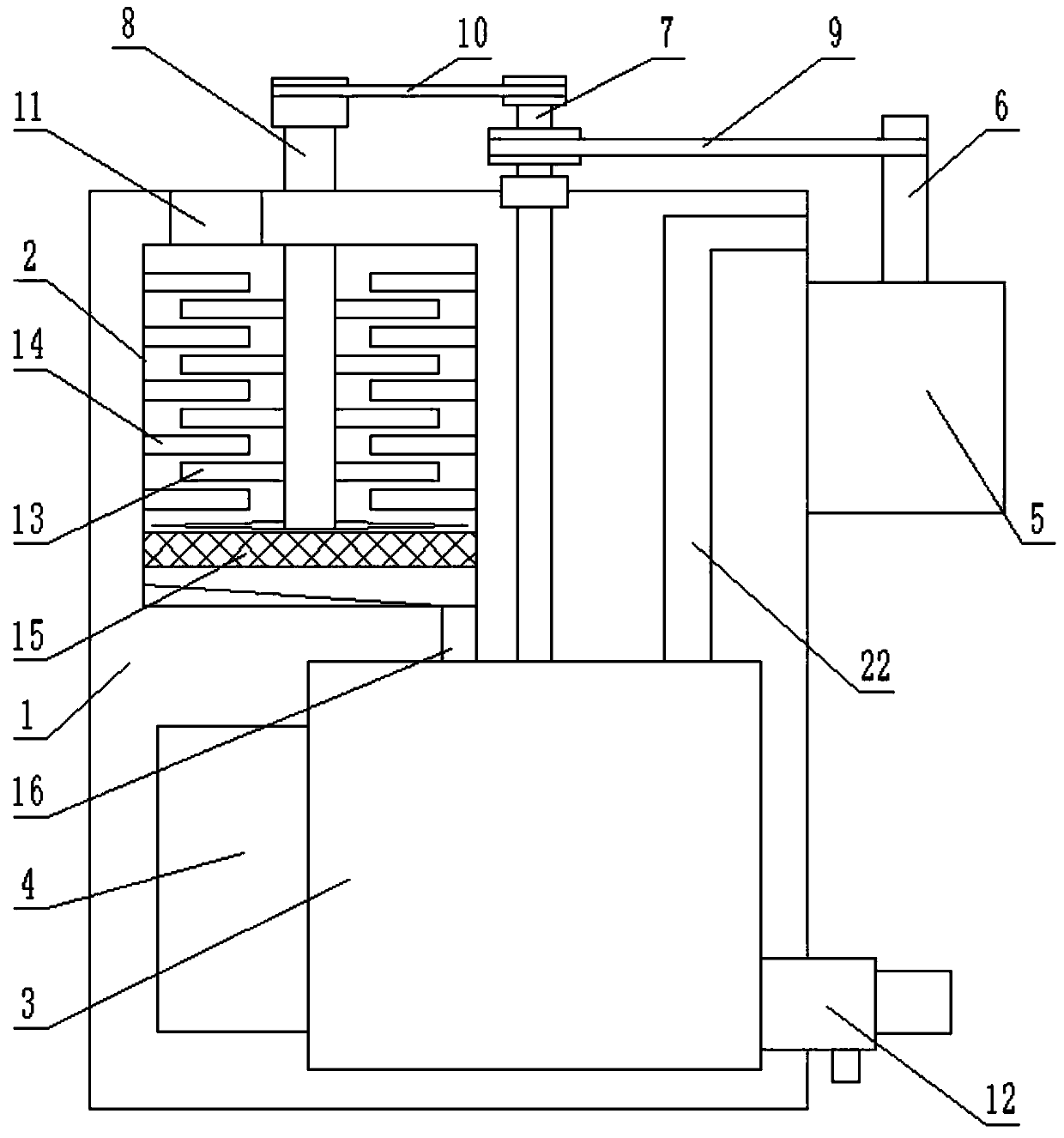

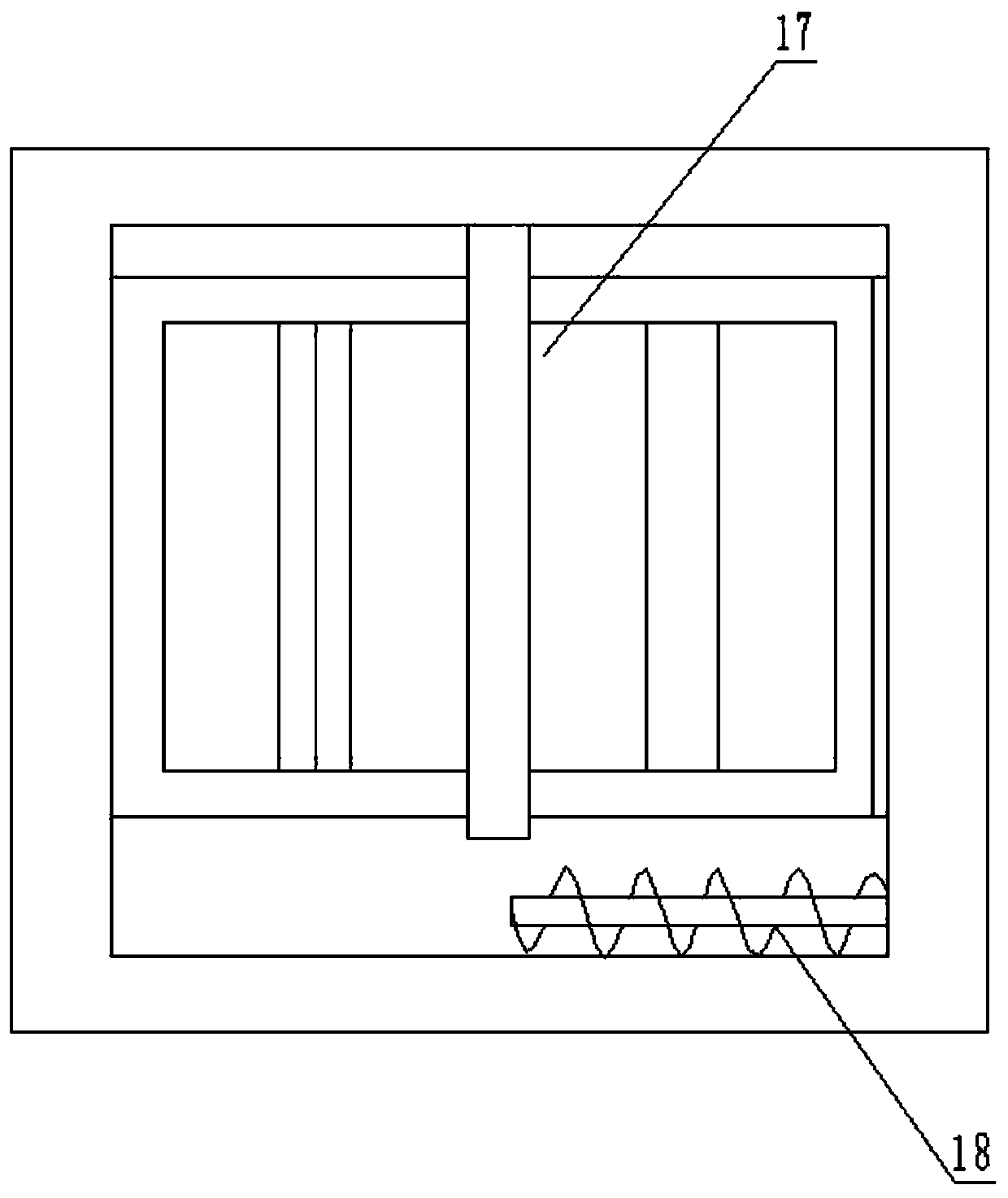

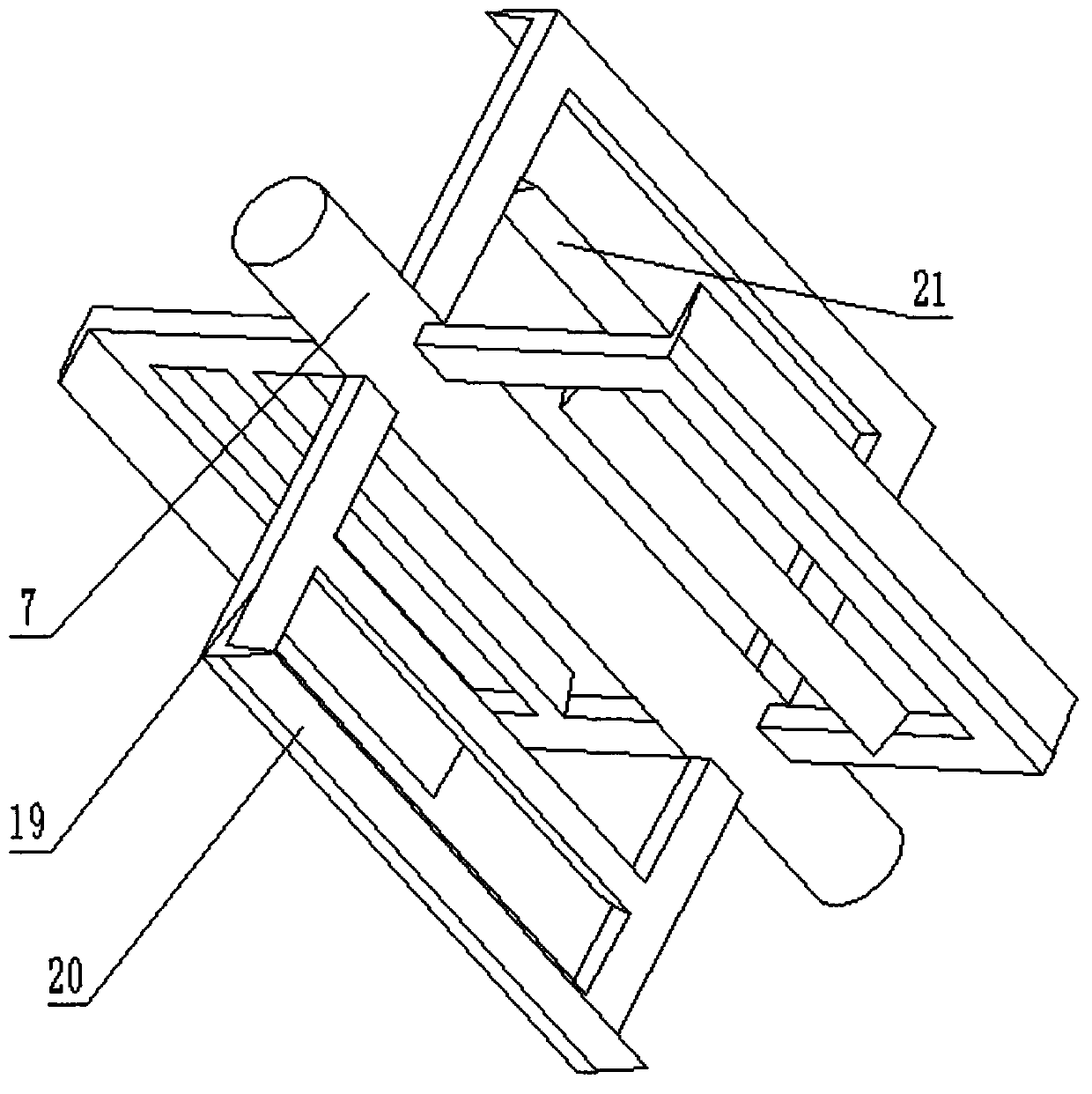

[0019] see Figure 1-3 , a raw material hot-melt device for plastic toy production, including a frame 1, a hot-melt box 3 and a heater 4 are arranged inside the frame 1, the hot-melt box 3 and the heater 4 are arranged side by side, and the heater 4 is used for hot-melt The box 3 is heated to heat and melt the raw materials entering the hot melting box 3. A crushing box 2 is also provided inside the frame 1. The crushing box 2 is located obliquely above the hot melting box 3. On the top of the crushing box 2, there is a The feed port 11, the bottom of the crushing box 2 is provided with a connecting pipe 16 connected to the hot melting box 3, and the raw material is crushed by the crushing box 2 and then transported to the hot melting box 3, thereby reducing the time required for hot melting. The hot melt box 3 is cylindrical, and the hot melt box 3 is provided with an agitator 17, the agitator 17 includes a first driven shaft 7 and a plurality of square frames 19, and the squ...

Embodiment 2

[0023] On the basis of Embodiment 1, the output cylinder 12 is provided with an output dragon 18 driven by a motor, and the front end of the output dragon 18 extends into the bottom of the hot melting tank 3, and a discharge cylinder 12 is provided at the bottom of the discharge cylinder 12. After the hot melting of the raw materials is completed, the motor drives the output dragon 18 to rotate, and the output dragon 18 drives the raw materials to move and output to the discharge port.

Embodiment 3

[0025] On the basis of Embodiment 1, the top of the hot melt box 3 is connected with a pressure-stabilizing exhaust pipe 22, and the other end of the pressure-stabilizing exhaust pipe 22 is connected to an external gas recovery device. In the box 3, the air that increases the pressure in the hot melting box 3 due to expansion due to heating and temperature rise is discharged, so as to avoid equipment damage caused by high pressure in the hot melting box 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com