Variable-diameter crushing type dry powder fire extinguisher and fault elimination method thereof

A fire extinguisher and pulverizing technology, which is applied in fire rescue, grain processing and other directions, can solve the problems of poor fire extinguishing effect, low frequency of fire incidents, low efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

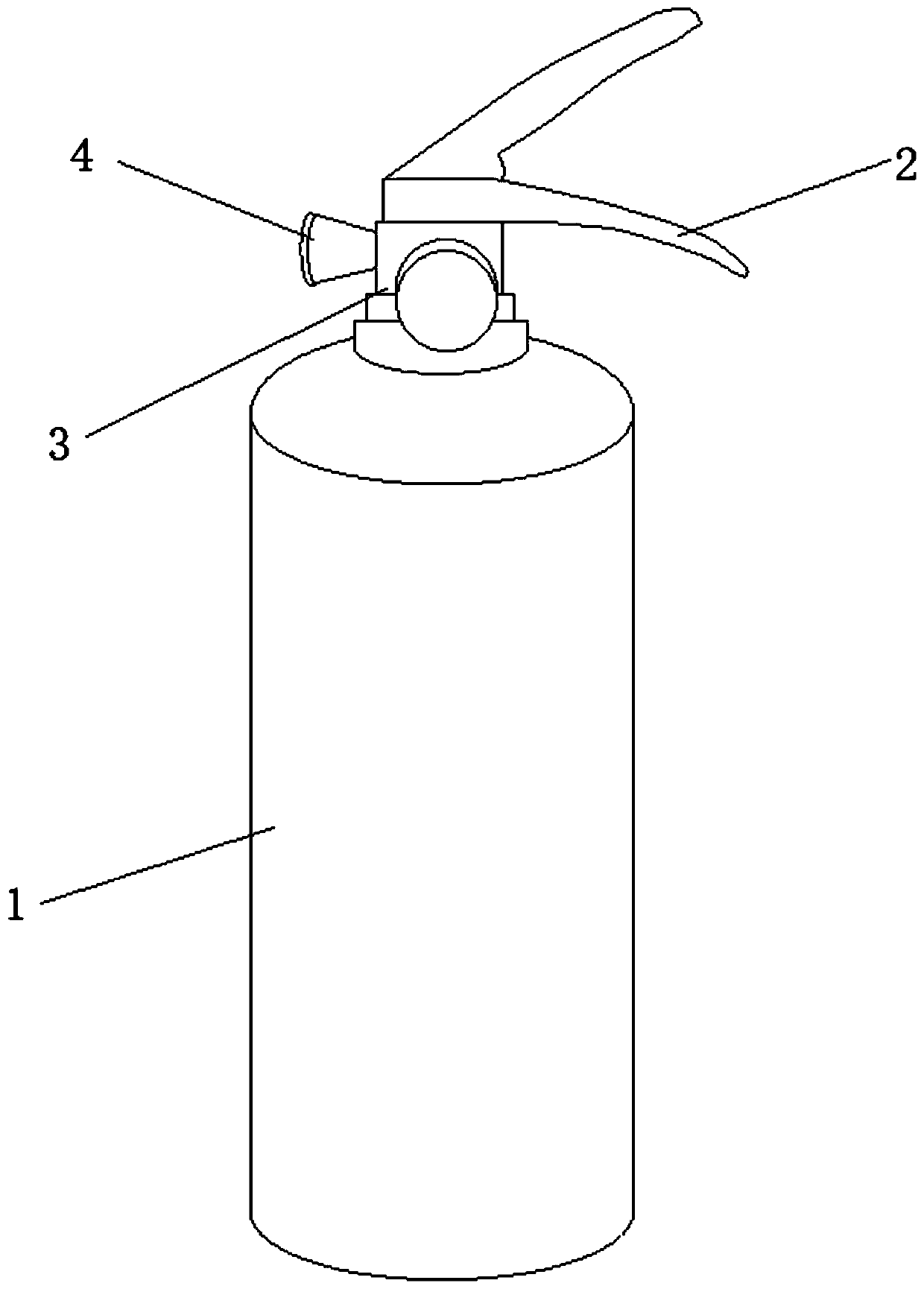

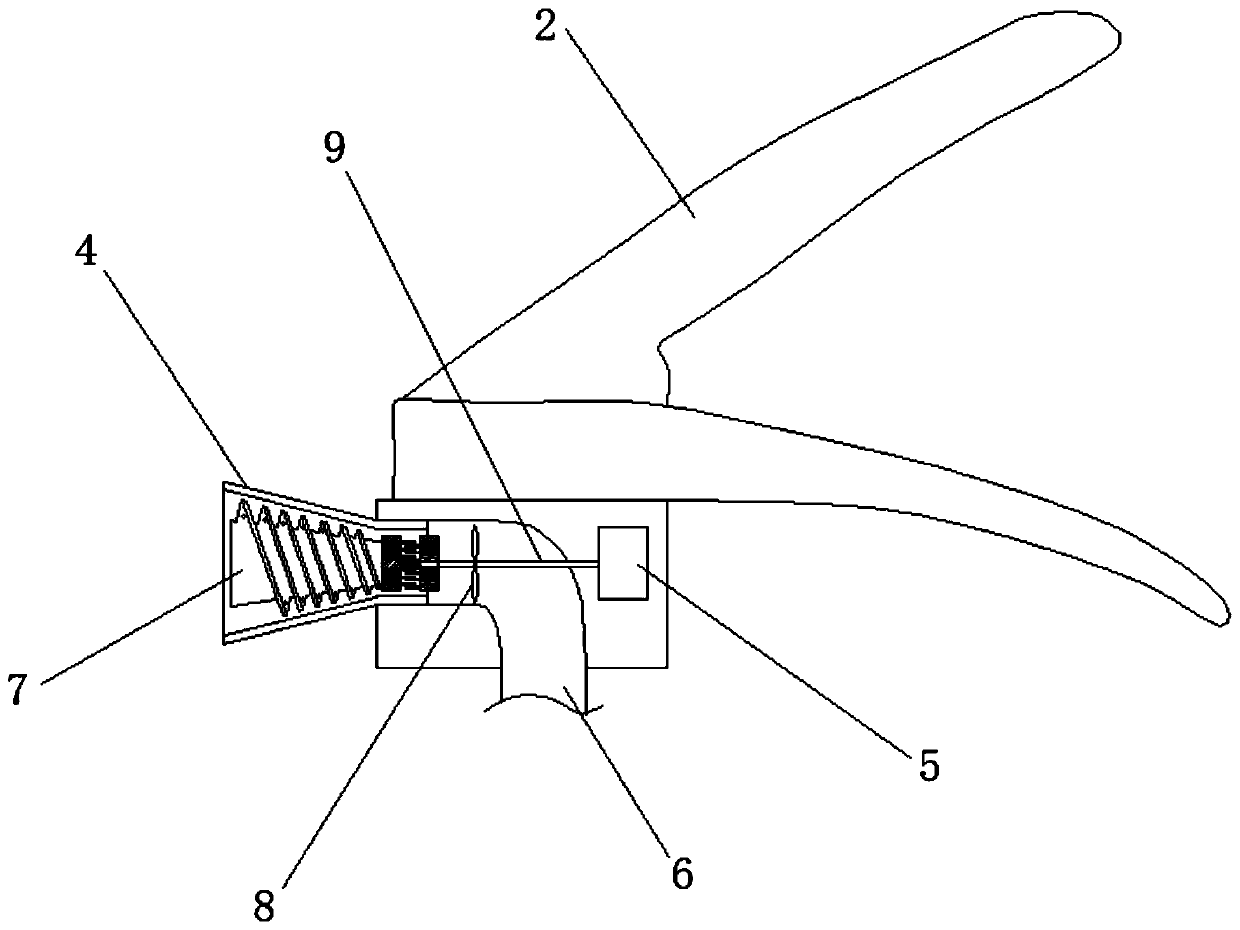

[0045] see figure 1 , a variable-diameter powder-type dry powder fire extinguisher, including a dry powder fire extinguisher body 1 with a spray head 3 and a pressure handle 2 connected to the upper end, and a powder spray port 4 connected to the end of the spray head 3 away from the pressure handle 2, please refer to figure 2 , the dry powder fire extinguisher body 1 is provided with a nozzle 6 inside, the upper end of the nozzle 6 extends to the nozzle 3 and is fixedly connected with the powder injection port 4, and the inner side of the powder injection port 4 is provided with a variable-diameter crushing mechanism;

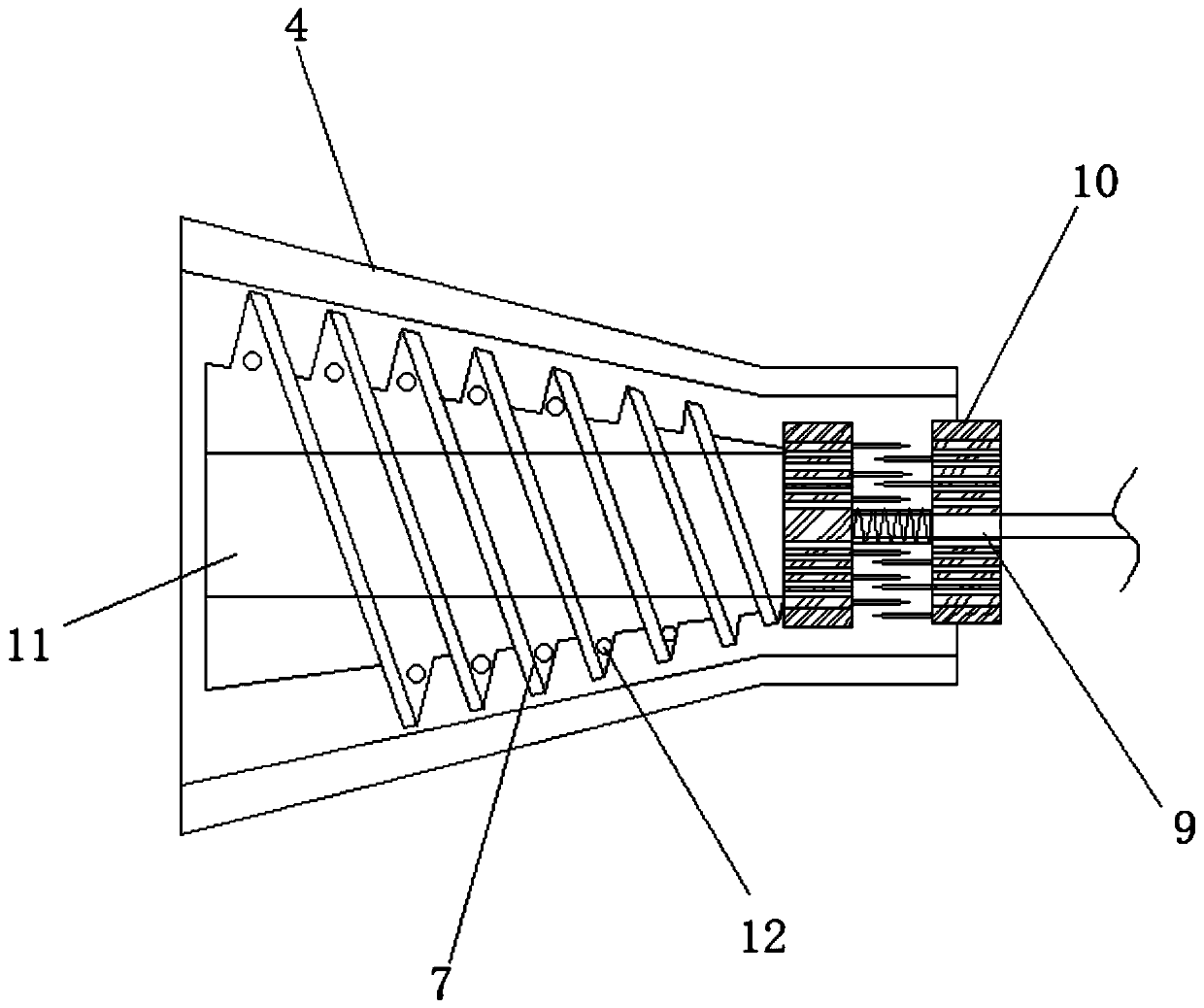

[0046] see figure 2 and image 3 , the variable-diameter pulverizing mechanism includes a variable-diameter pulverizing structure 7, a screening assembly 10, and a driving part, and the driving part includes a micro-driving device 5, and the micro-driving device 5 can use a micro-motor, such as a 19mm-length miniature motor of DMK24-DEC2430. The motor and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com