3D printing semi-pelvic prosthesis

A 3D printing, half pelvis technology, applied in 3D printing, prosthesis, additive manufacturing, etc., can solve the problem that the center of the acetabular cup structure cannot accurately locate the patient's original acetabular center, the hip joint function, and the weight of the prosthesis cannot be obtained. Increase the long-term stability, increase the probability of bone ingrowth, and overcome the loosening of the prosthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

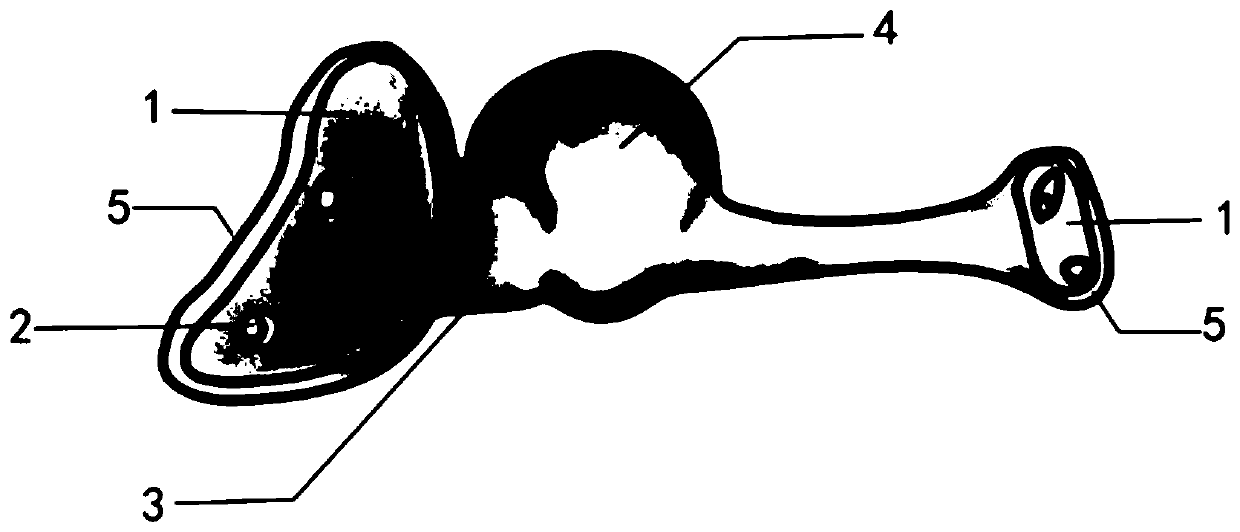

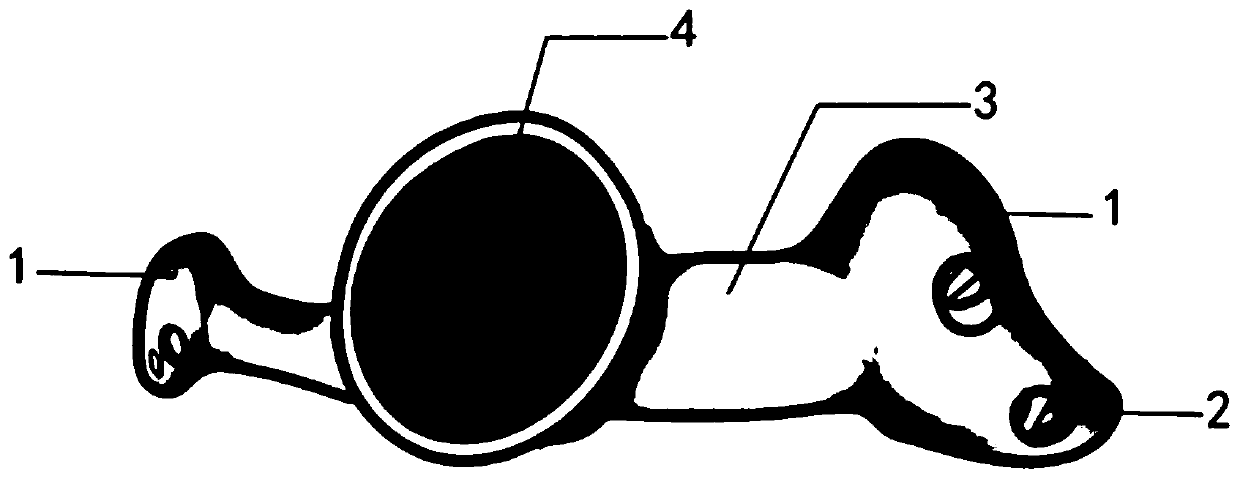

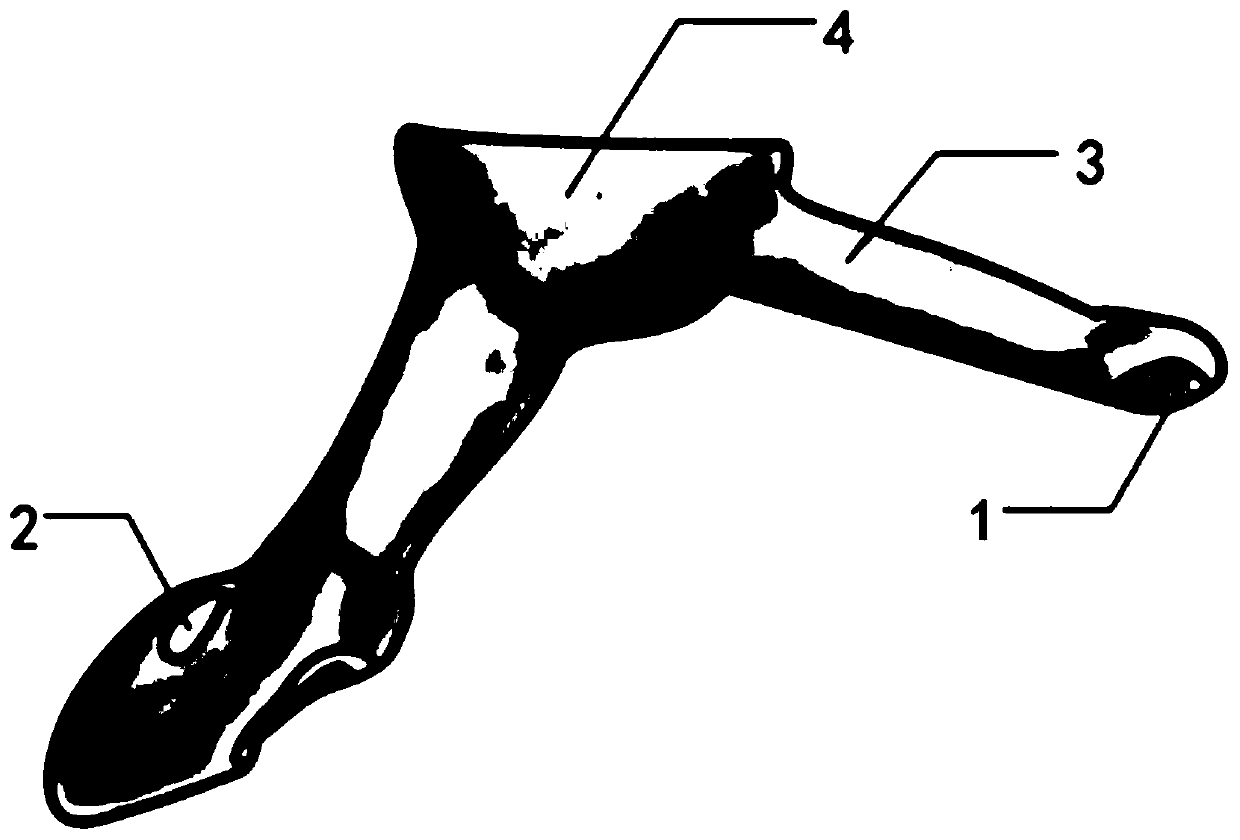

[0030] see figure 1 , figure 2 , image 3 and Figure 4 The 3D printed hemipelvic prosthesis of the present invention is based on preoperative CT and MRI three-dimensional image fusion digital model for preoperative planning, to determine the scope of surgical resection, to obtain parameters such as pelvic osteotomy plane and acetabular position, and design according to these parameters Personalized prostheses for specific patients are produced, and after the design is completed, computer simulation is carried out to simulate the installation, and metal 3D printing equipment is used to prepare the actual prosthesis. During the operation, the 3D printed guide plate or computer-aided navigation system is used to complete the precise resection, and the osteotomy plane can fit perfectly with the contact surface of the prosthesis.

[0031] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com