Automatic shoe tree manufacturing method and automatic shoe tree manufacturing structure

A production method and technology for shoe lasts, which are applied to shoe lasts, footwear, clothing, etc., can solve the problems of missing displacement, inaccurate positioning, positioning errors, etc., and achieve uniform specifications, accurate dimensions, and zero damage rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to have a more complete and clear disclosure of the technical content used in the present invention, the purpose of the invention and the effects achieved, the following detailed description is now given, and please also refer to the disclosed drawings and figure numbers:

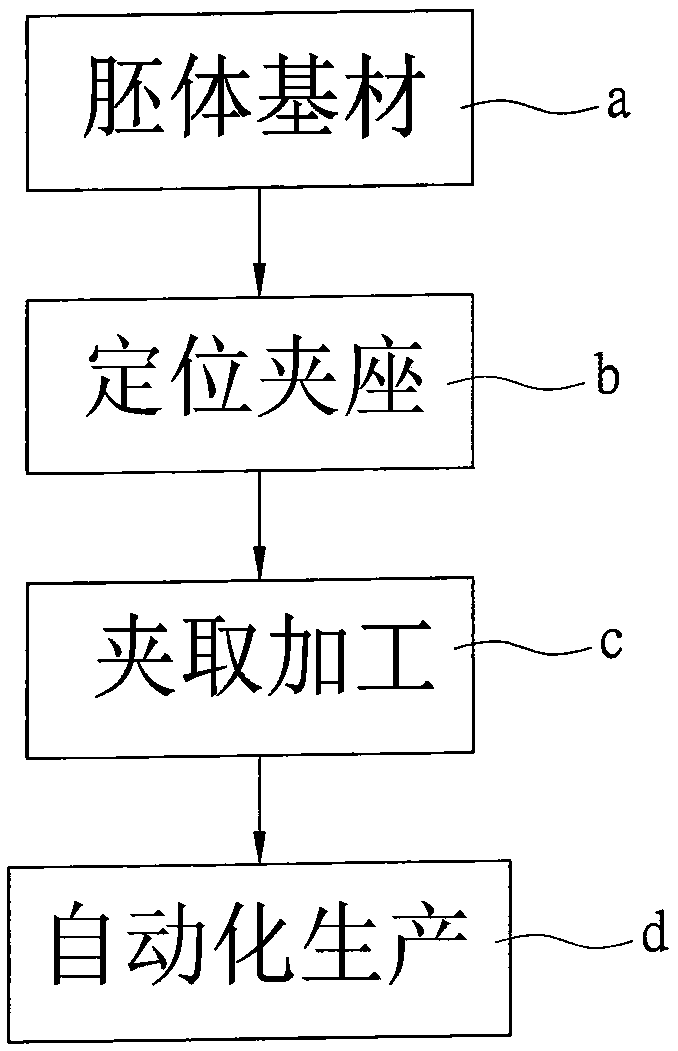

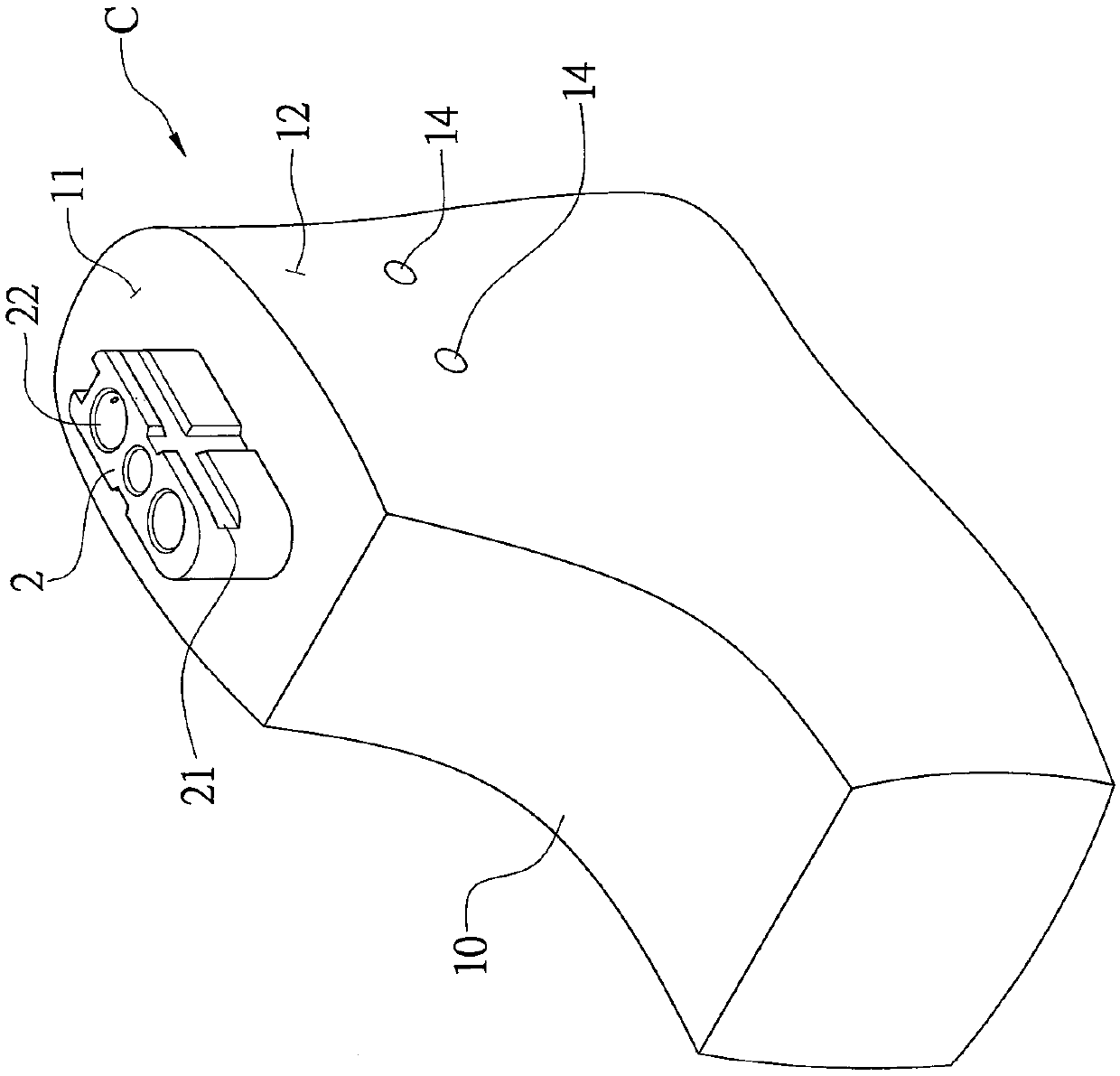

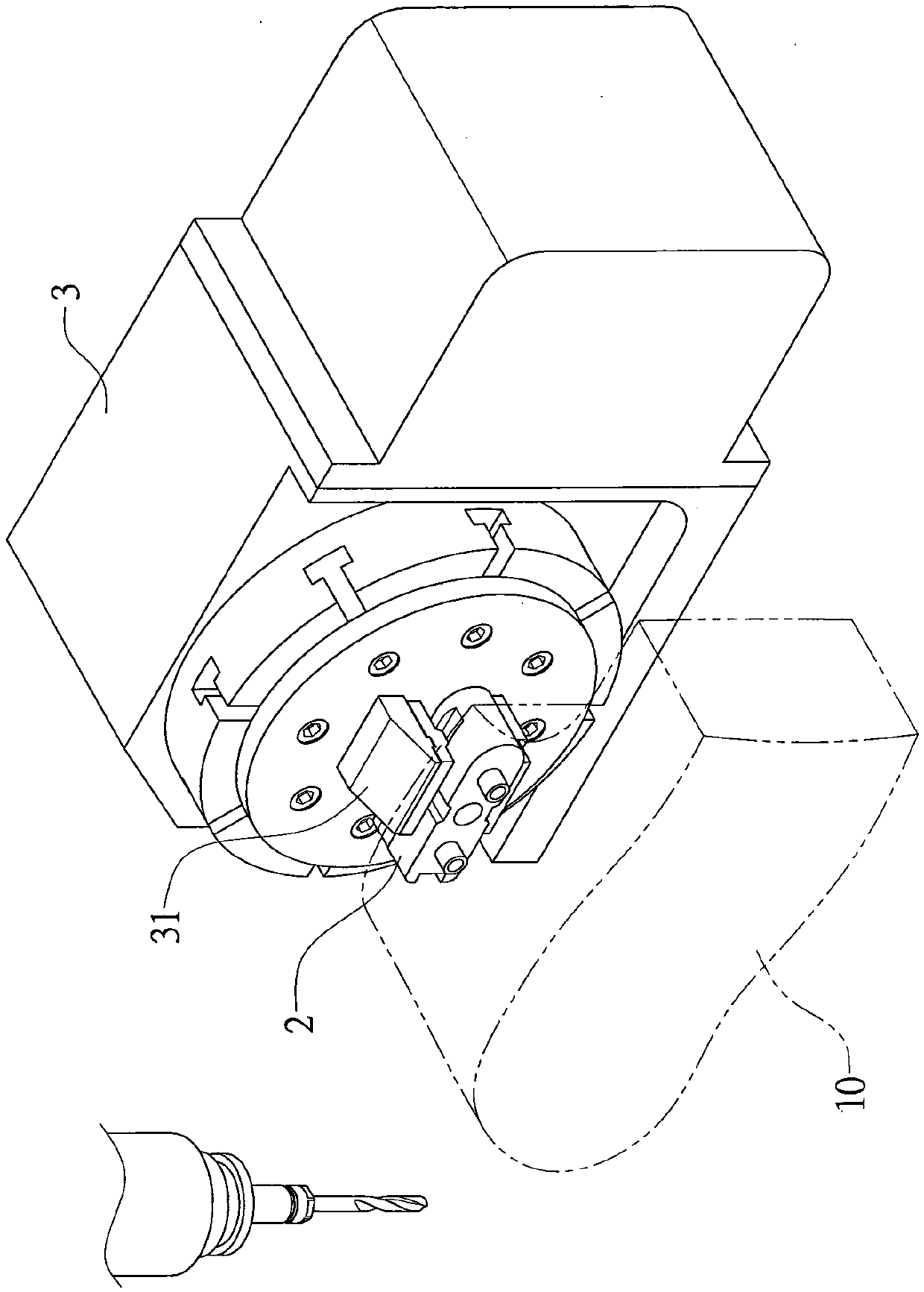

[0050] First of all, the actual application technology and means of the present invention, please refer to Figure 1 ~ Figure 2As shown, it is a schematic diagram of blocks and steps of the automatic shoe last manufacturing method and its structure of the present invention, which mainly locks and positions a clamping seat 2 on the end surface of an embryo base material 10, and the clamping seat 2 passes through a The chuck 31 of the automatic processing equipment 3 clamps, and mills the outer surface of the base material 10 with the chuck 2 as a reference, and completes the shape of a shoe last body 1 .

[0051] Through the above-mentioned production method, the sequence of its detailed proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com