Preparation method of canned corn

A technology of canned corn and corn, which is applied to the preservation of edible seeds, the preservation of seeds through pressure changes, food preservation, etc., which can solve the problems of strong slag feeling, intolerance to storage of sweet corn fresh buds, and insufficient delicate taste, etc., and achieve improved quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

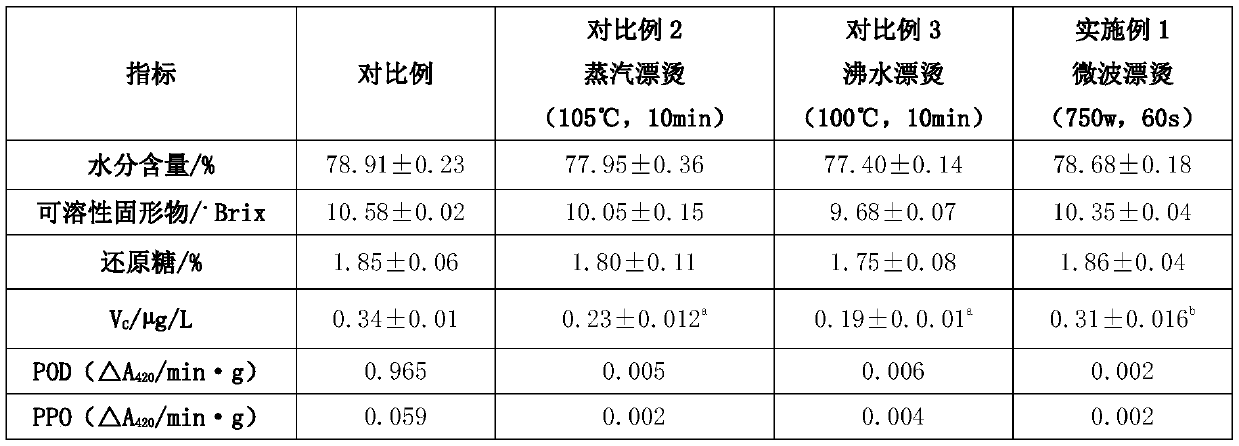

Embodiment 1

[0019] A kind of preparation method of canned corn, the final temperature of corn vacuum precooling is 8 DEG C rapidly, microwave blanching (750w, 60s) inactivates enzyme, after adding xanthan gum, sodium alginate, konjac gum compound glue (volume ratio is 3:1:6), followed by ultra-high pressure sterilization at 500-600 MPa for 15-20 min; preferably, ultra-high pressure sterilization at 600 MPa for 15 min, and then adding nisin to obtain canned corn.

Embodiment 2

[0021] A preparation method of canned corn: the final temperature of corn is rapidly pre-cooled in vacuum to 10°C, microwave blanching is used to inactivate enzymes, and after adding xanthan gum, sodium alginate, and konjac gum compound glue (volume ratio is 3:1:6 ). Then carry out ultra-high pressure sterilization at 500-600 MPa for 15-20 minutes; preferably, sterilize at 600 MPa ultra-high pressure for 15 minutes, and then add nisin to obtain canned corn.

Embodiment 3

[0023] A preparation method of canned corn: quickly precooling the corn in vacuum to a final temperature of 9°C, blanching in microwave to inactivate enzymes, adding xanthan gum, sodium alginate, and konjac gum compound glue (volume ratio is 3:1:6 ). Then carry out ultra-high pressure sterilization at 500-600 MPa for 15-20 minutes; preferably, sterilize at 600 MPa ultra-high pressure for 15 minutes, and then add nisin to obtain canned corn.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com