Large-caliber split type conductive slip ring suitable for high-humidity environment

A conductive slip ring and large-diameter technology, which is applied in the direction of rotating collectors, circuits, collectors, etc., can solve the problems of inability to achieve external sealing, insulation resistance drop, signal interference, etc., to ensure integrity and stability, prevent Signal crosstalk, the effect of isolating signal interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

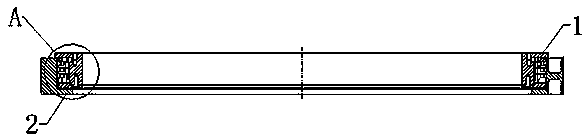

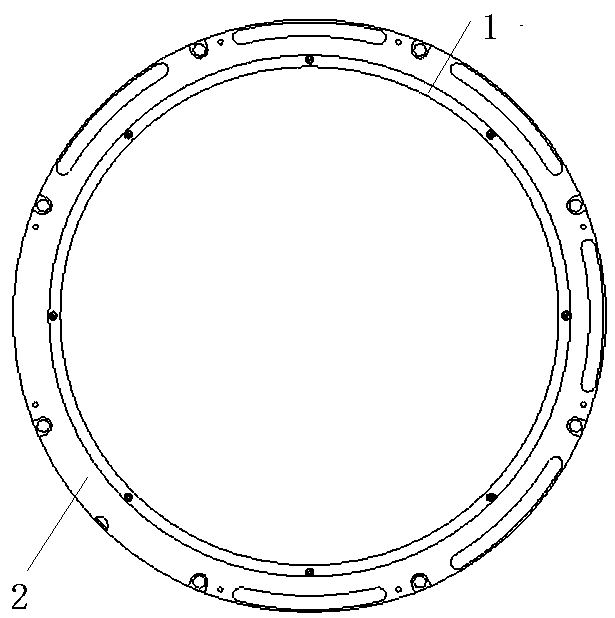

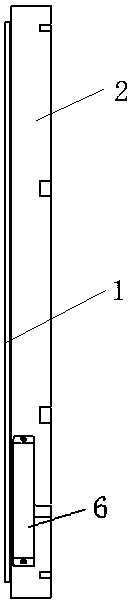

[0023] A large-diameter split-type conductive slip ring suitable for high-humidity environments, consisting of a central shaft 1, a combined bracket 2, a ring piece 3, an insulating gasket 4, a pressure plate 5, and a brush assembly 6; wherein the insulating gasket 4 is POM (polyoxymethylene) is made of a stepped gasket with a high inside and a low outside, and a line-passing gap 7 is milled on the inner ring of the insulating gasket 4 .

[0024] During the assembly process of the ring piece, the ring piece 3 is set on the outer circle of the raised part 8 of the insulating gasket 4, and the wire of the ring piece 3 is passed through the wire passing gap 7 of the insulating gasket 4, and two adjacent The wire-passing notch 7 of each insulating spacer 4 is staggered by 180°.

[0025] The total thickness of the insulating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com