Hydraulic climbing template monitoring and analyzing method

A technology of climbing templates and analysis methods, applied in the direction of measuring devices, CAD numerical modeling, instruments, etc., to achieve the effect of ensuring precision and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

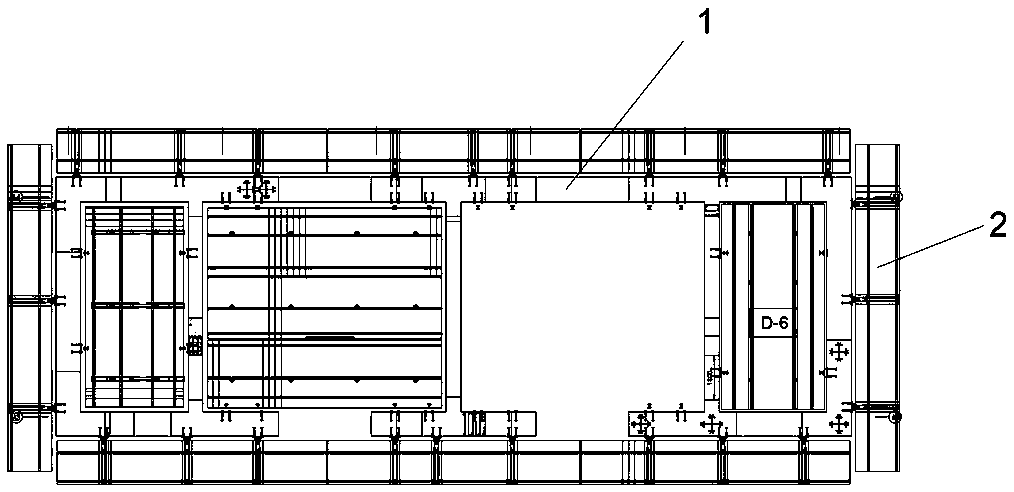

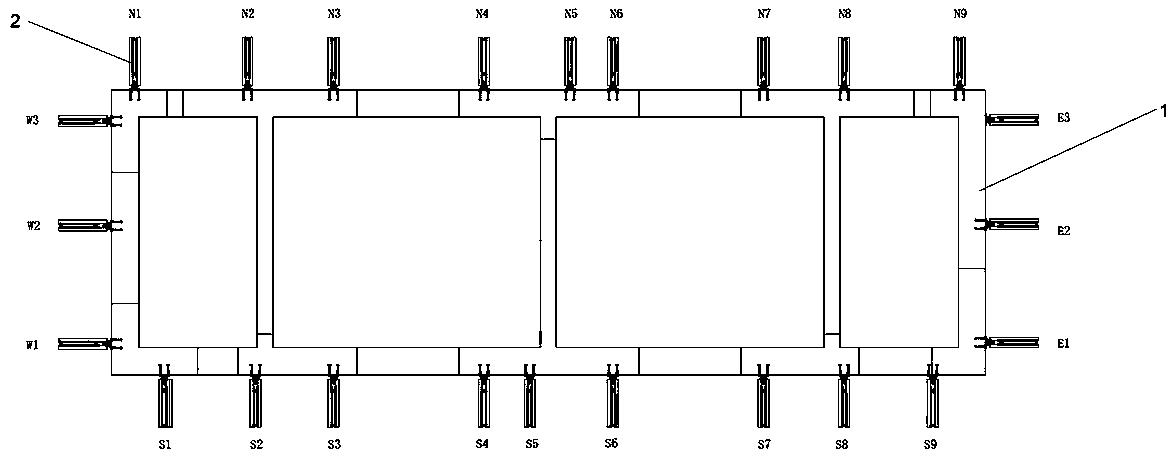

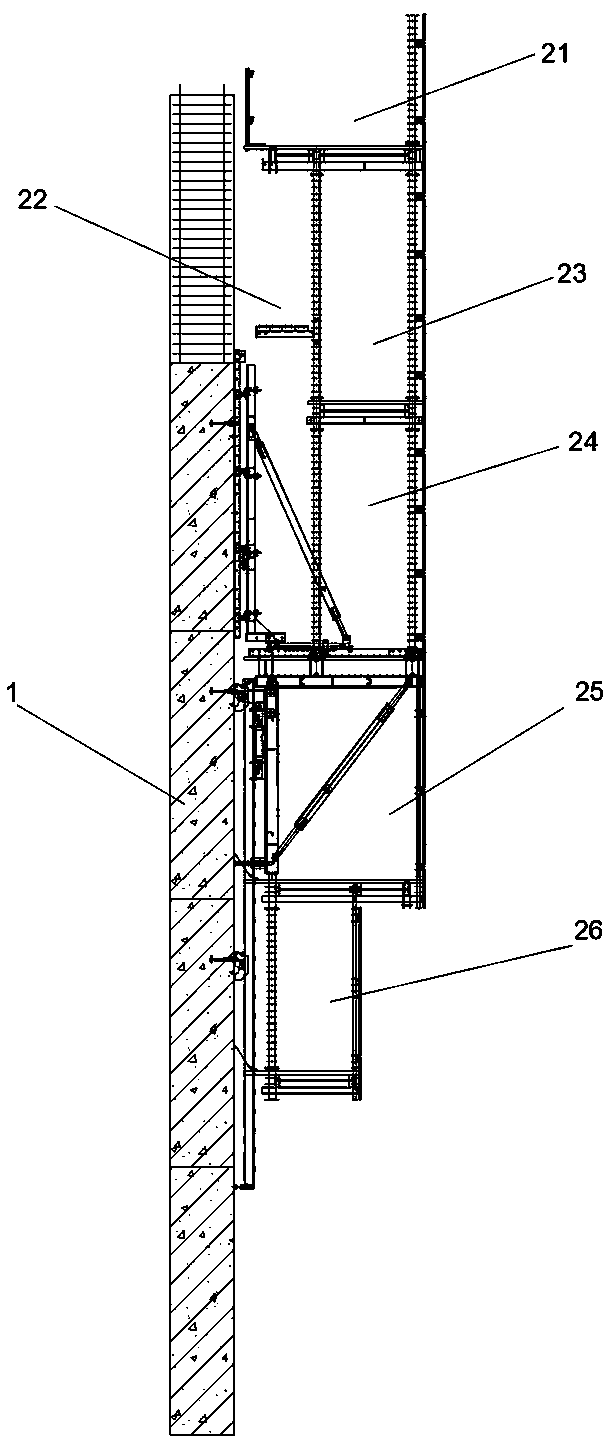

[0030] Taking the frame shear wall structure of a certain building as an example, such as figure 1 with figure 2 As shown, the core shaft 1 of the project is divided into four shafts inside, with two large shafts in the middle and two small shafts outside. N, S, E, and W in the figure represent the installation of the hydraulic climbing formwork 2 in the north, south, east, and west respectively. Azimuth, numbers after N, S, E, and W represent the position of the hydraulic climbing formwork 2, and each position is provided with a set of hydraulic cylinders and a set of power units. The upper and lower two long sides of the core tube 1 respectively have 9 machine positions to climb up as a whole. The main platform on each long side has a total length of 32.3 meters and is divided into three installation units. The lengths of each unit platform are 11m, 10.3m and 11m respectively. After installation, the platform beams of each unit are welded into a whole with steel plates. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com