Heat isolating structure of heating core

A heating core, electric heating tube technology, applied in fluid heaters, lighting and heating equipment, etc., can solve the problems of reduced service life of containers, reduced product competitiveness, and increased material costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

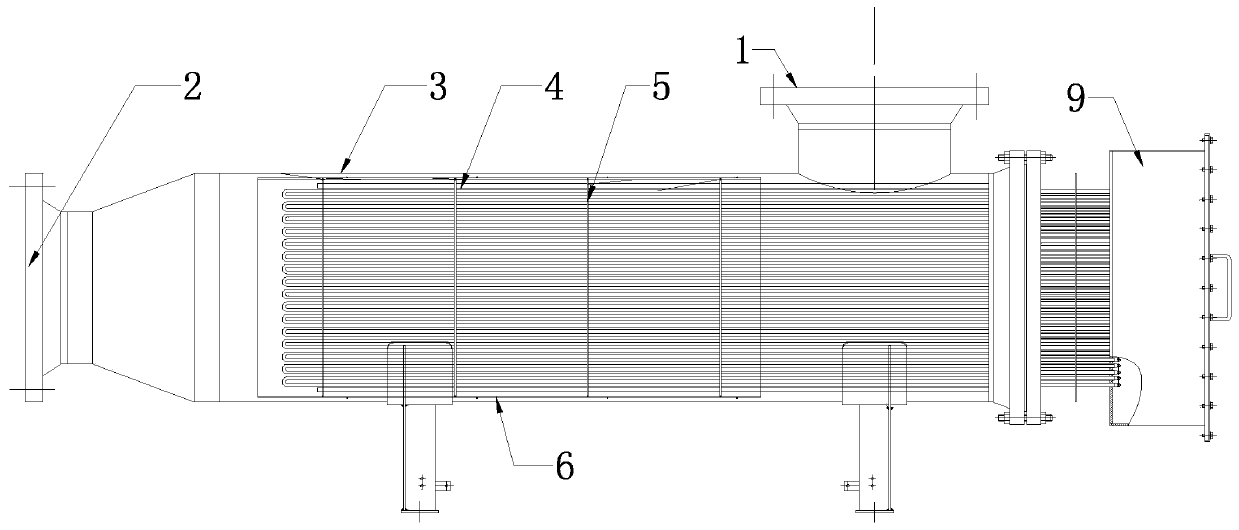

[0014] The heat insulation structure of the heating core of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

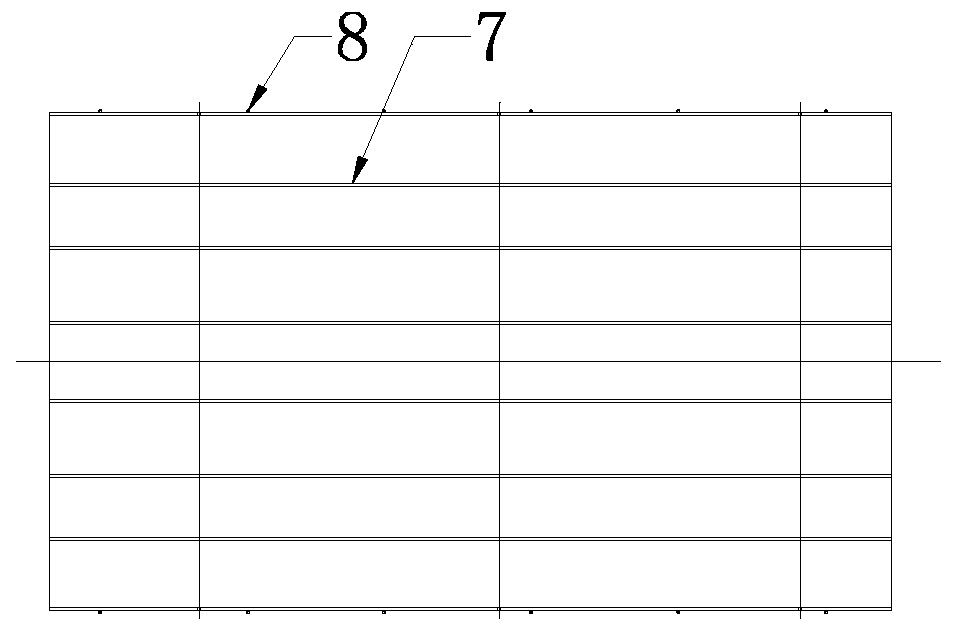

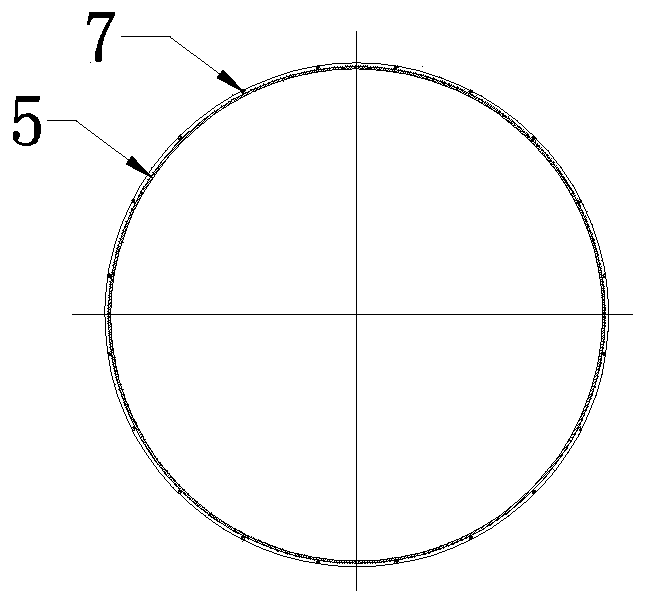

[0015] As shown in the figure, the heat insulation structure of the heating core of the present invention includes a container 3 with a medium inlet 1 and a medium outlet 2 and an electric heating tube 4 located in the container, and the electric heating tube 4 passes through a plurality of support nets (baffles) 5 Carry out positioning installation, the specific installation structure is as follows figure 1 As shown, the electric heating tube is positioned and fixed as a whole through a series of evenly arranged support nets. The electric heating tube 4 is fixed and installed through the support member 5 to form an integral heating core structure. The electric heating tube 4 and the container 3 There is a heat insulating cylinder 6, the two sides of the heat insulating cylinder are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com