Fixed-point bonding double-layer 3D fabric and manufacturing process thereof

A 3D and fabric technology, applied in the field of fixed-point consolidation of double-layer 3D fabrics and its manufacturing process, can solve the problem of low pattern retention and achieve the effect of improving pattern retention, ensuring softness, and enhancing the three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

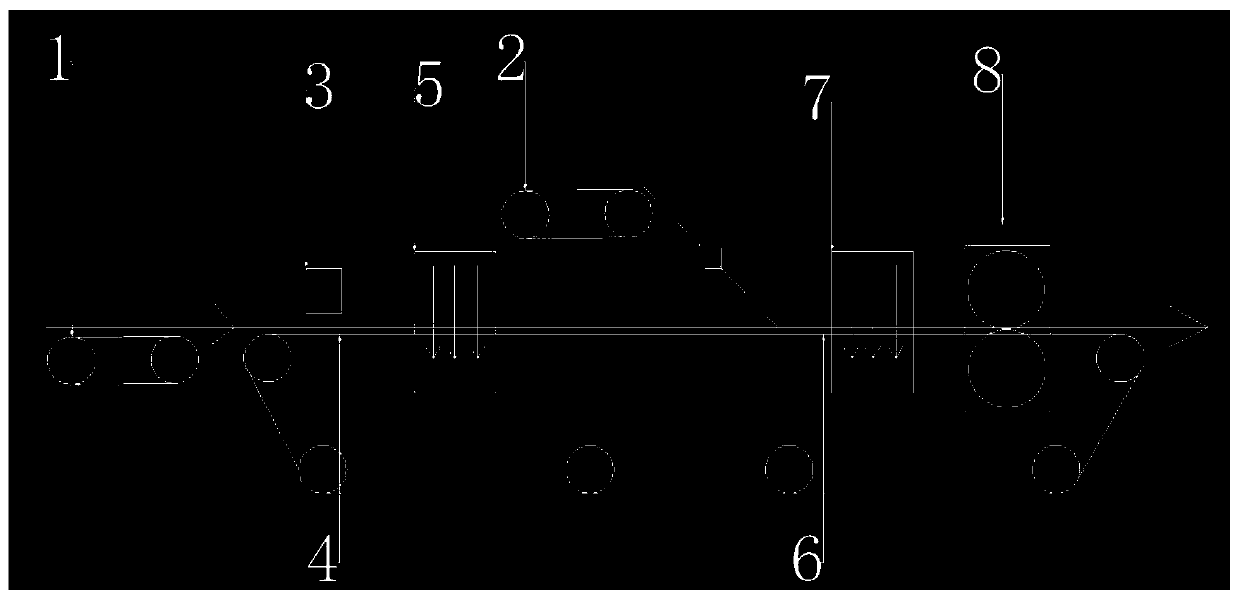

Method used

Image

Examples

Embodiment 1

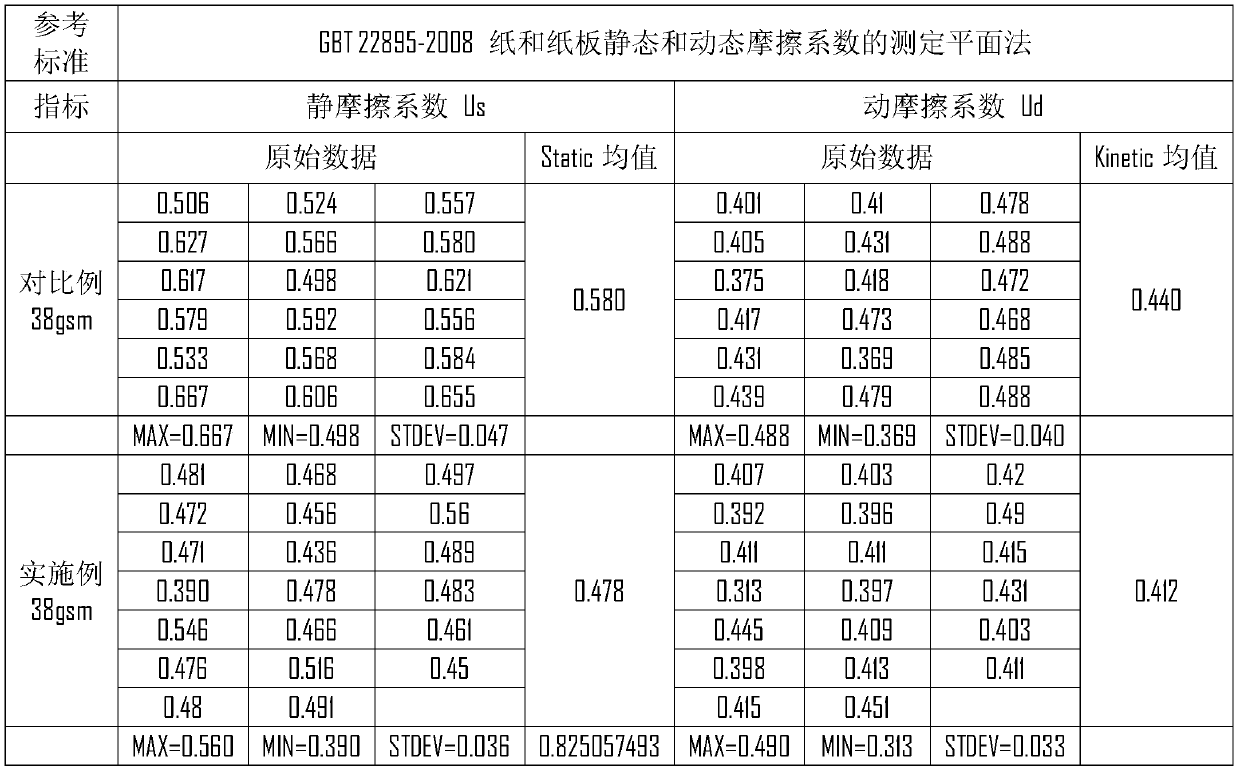

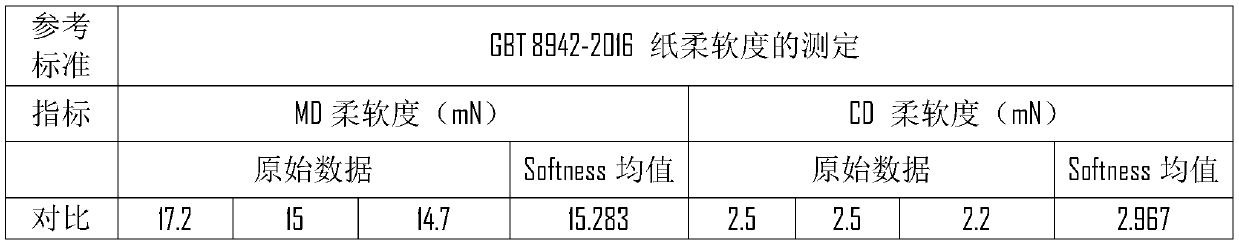

[0025] Embodiment 1: a fixed-point consolidation double-layer 3D fabric, including a first layer of fiber web arranged on the bottom layer, a second layer of fiber web arranged on the top layer, and a filling fiber arranged on the first layer of fiber web, the filling fiber There is a three-dimensional flower-shaped part raised upwards, a first bonding part is provided between the edge of the three-dimensional flower-shaped part and the second layer of fiber net, and hot-melt particles are arranged on the edge of the three-dimensional flower-shaped part, so that The melting temperature of the hot-melt particles is lower than the hot-melt temperature of the ES fiber skin, a second bonding portion is provided between the first layer of fiber web and the second layer of fiber web, and a drainage hole is provided on the second layer of fiber web , the fibers of the first layer of fiber web use PP / PP with a fineness of 2 Denier, the grammage of the first layer of fiber web is 12gsm,...

Embodiment 2

[0033] Embodiment 2: a fixed-point consolidation double-layer 3D fabric, including a first layer of fiber web arranged on the bottom layer, a second layer of fiber web arranged on the top layer, and a filling fiber arranged on the first layer of fiber web, the filling fiber There is a three-dimensional flower-shaped part raised upwards, a first bonding part is provided between the edge of the three-dimensional flower-shaped part and the second layer of fiber net, and hot-melt particles are arranged on the edge of the three-dimensional flower-shaped part, so that The melting temperature of the hot-melt particles is lower than the hot-melt temperature of the ES fiber skin, a second bonding portion is provided between the first layer of fiber web and the second layer of fiber web, and a drainage hole is provided on the second layer of fiber web , the fibers of the first layer of fiber web use PP / PE sheath-core fibers with a fineness of 3 deniers, the weight of the first layer of f...

Embodiment 3

[0041]Embodiment 3: a fixed-point consolidation double-layer 3D fabric, including the first layer of fiber webs arranged on the bottom layer, the second layer of fiber webs arranged on the top layer, and the filling fibers arranged on the first layer of fiber webs, the filling fibers There is a three-dimensional flower-shaped part raised upwards, a first bonding part is provided between the edge of the three-dimensional flower-shaped part and the second layer of fiber net, and hot-melt particles are arranged on the edge of the three-dimensional flower-shaped part, so that The melting temperature of the hot-melt particles is lower than the hot-melt temperature of the ES fiber skin, a second bonding portion is provided between the first layer of fiber web and the second layer of fiber web, and a drainage hole is provided on the second layer of fiber web , the fibers of the first layer of fiber web use side-by-side bi-component fibers, the fineness is 4 deniers, the weight of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fiber fineness | aaaaa | aaaaa |

| Fiber fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com