Single-mode fiber and fabrication method thereof

A single-mode optical fiber, core layer technology, applied in clad optical fibers, glass optical fibers, glass manufacturing equipment, etc., can solve the problems of cumbersome steps, extremely high requirements for fiber drawing, poor uniformity of radial refractive index, etc. Effective area, reduce optical power density, and improve the effect of optical power intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

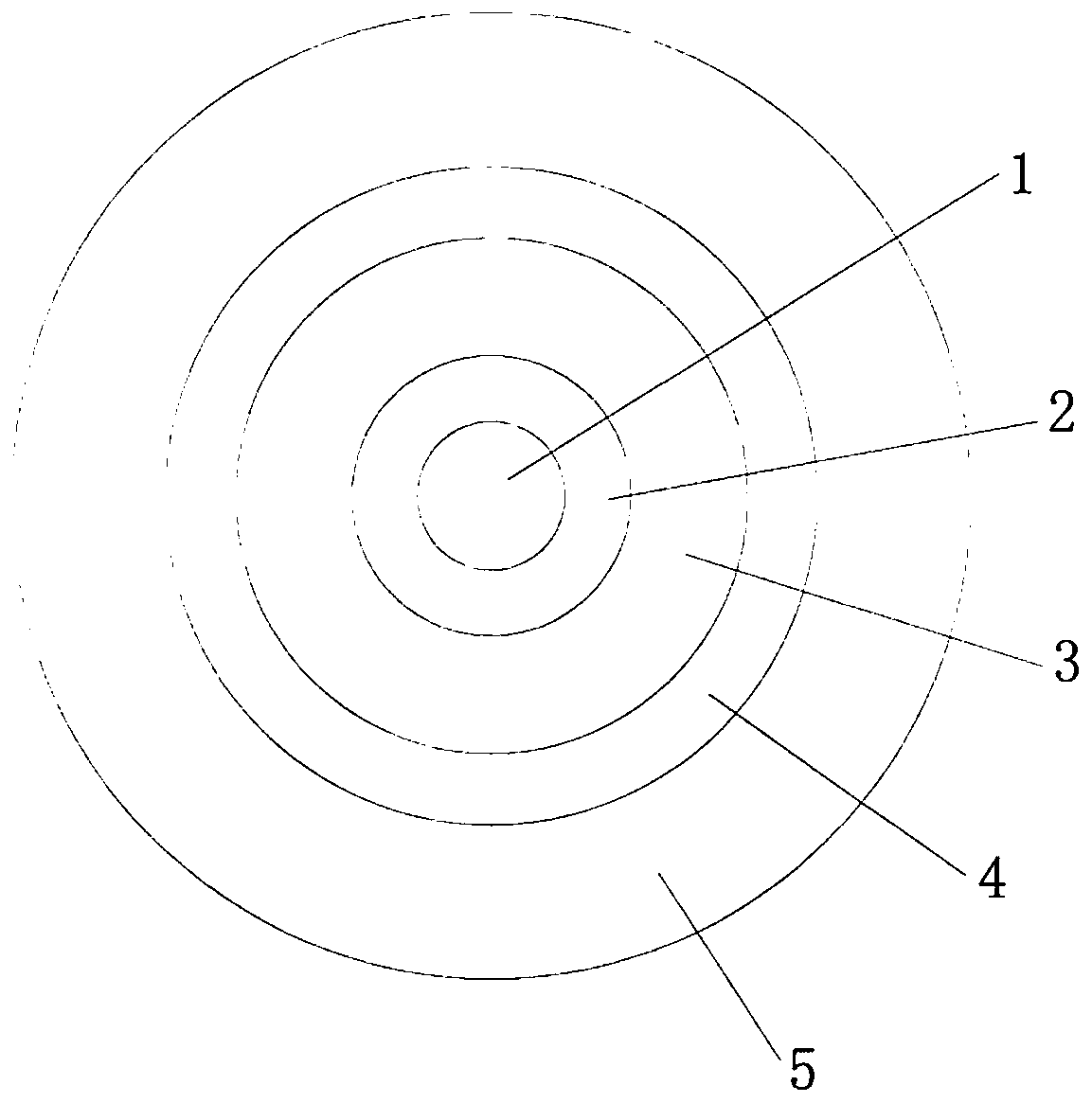

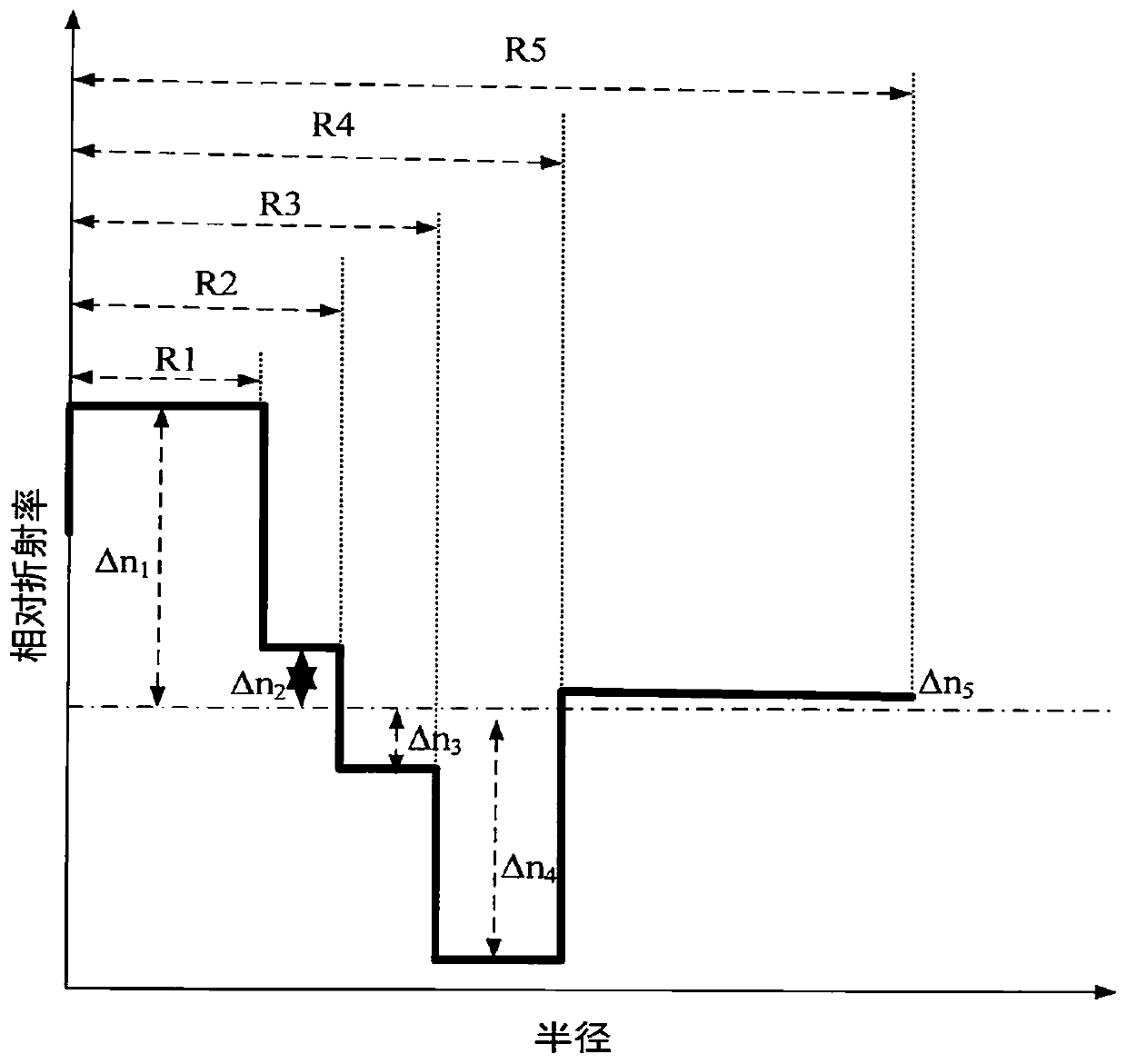

[0059] Such as figure 1 As shown, it is a cross-sectional view of a single-mode optical fiber. The bare optical fiber includes a core layer and an inner cladding layer. The core layer includes a first core layer 1 and a second core layer 2. The radius of the first core layer 1 is R 1 3.5~5.5μm, the relative refractive index difference is 0.2%≤Δ 1 ≤0.35%, second core layer 2 radius R 2 5~7μm, the relative refractive index difference is 0.15%≤Δ 2 ≤0.25%, the refractive index radius of the inner cladding layer 3 is 24 μm to 36 μm, the ratio of the radius of the inner cladding layer 3 to the second core layer 2 is 4.5 to 6, and the relative refractive index difference is -0.12%≤Δ 3 ≤0%. The cladding includes a depressed cladding 4 and an outer cladding 5, the radius of the depressed cladding 4 is 40 μm to 50 μm, and the relative refractive index difference is -0.40%≤Δ 4 ≤-0.28%, the outer cladding 5 is a high-hardness pure quartz sleeve, and the radius of the outer cladding 5 ...

Embodiment 2

[0066] A method for preparing a single-mode optical fiber in which the center of the first core layer in the refractive index profile (RIP) is a flat-top distribution, comprising the steps

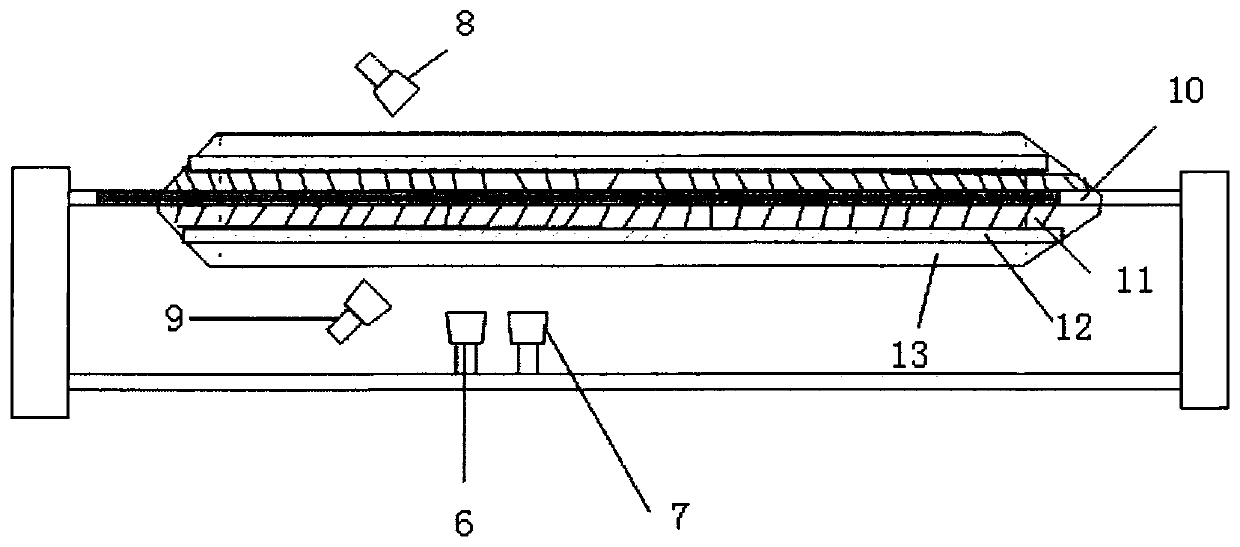

[0067] The core rod is prepared by OVD external vapor deposition. The core rod is divided into the first core layer 1, the second core layer 2 and the inner cladding layer 3. Four torches are set in the deposition lathe, and two vertical torches are set on the pre-installed ceramic target. At 200-300mm directly below the stick (length 2000-2200mm, diameter 6mm-8mm), the vertical blowtorches are arranged in parallel along a straight line, and the spraying direction is perpendicular to the ceramic target rod. They are respectively named the first blowtorch and the second blowtorch; the other two blowtorches are distributed On both sides of the main axis of the pre-installed ceramic target rod, each is pre-fixed at an angle of 45° to the horizontal plane, and they are named the third blowtorch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com