Sludge mixed burning system

A sludge and weighing bin technology, applied in the field of sludge co-firing system, can solve the problems that sludge is easy to be invaded by water, sludge volume is difficult to measure, and pollution is large

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

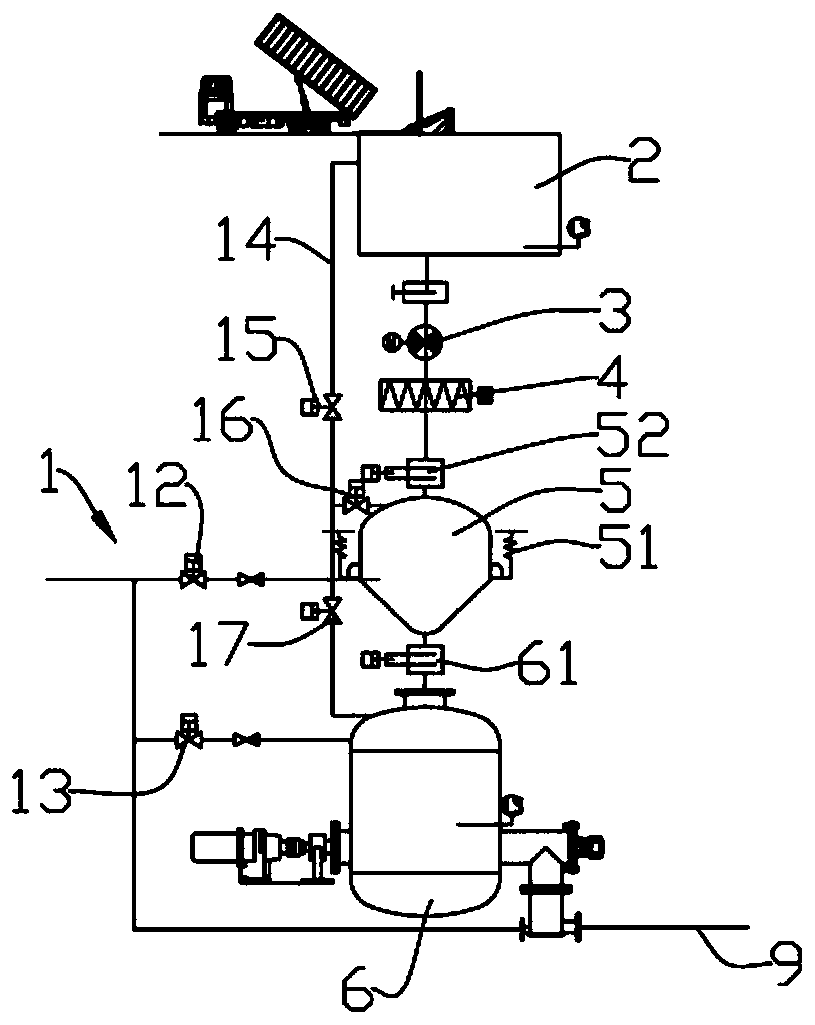

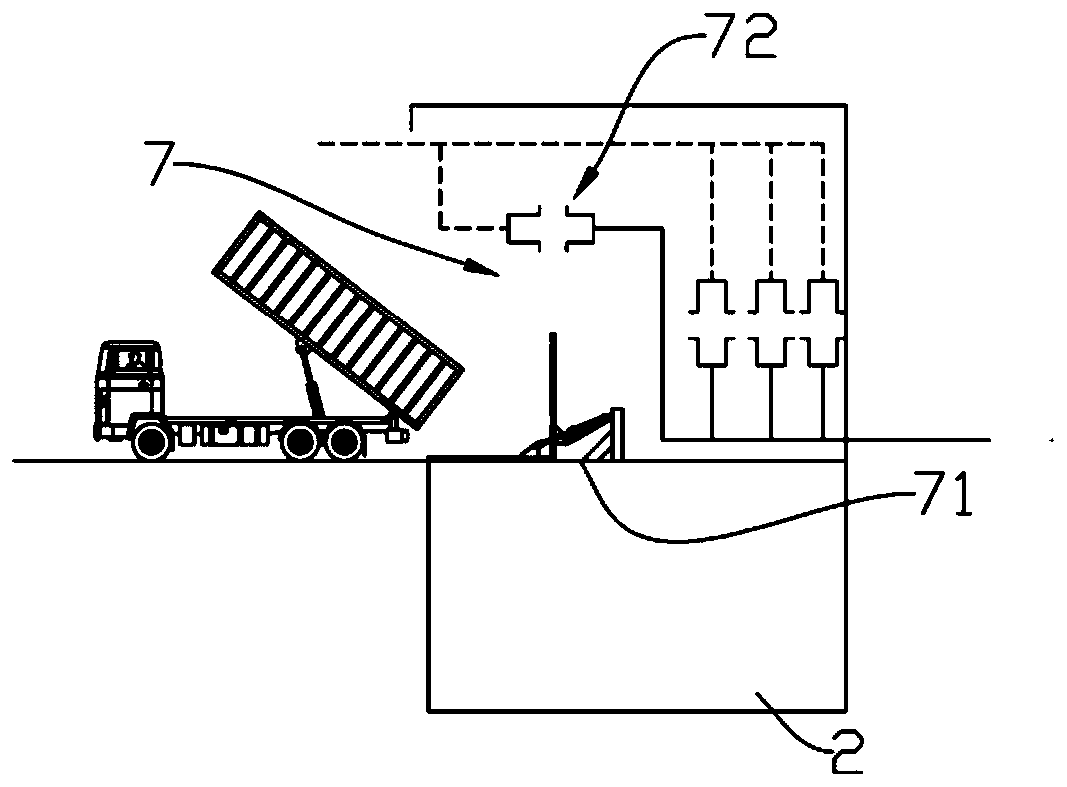

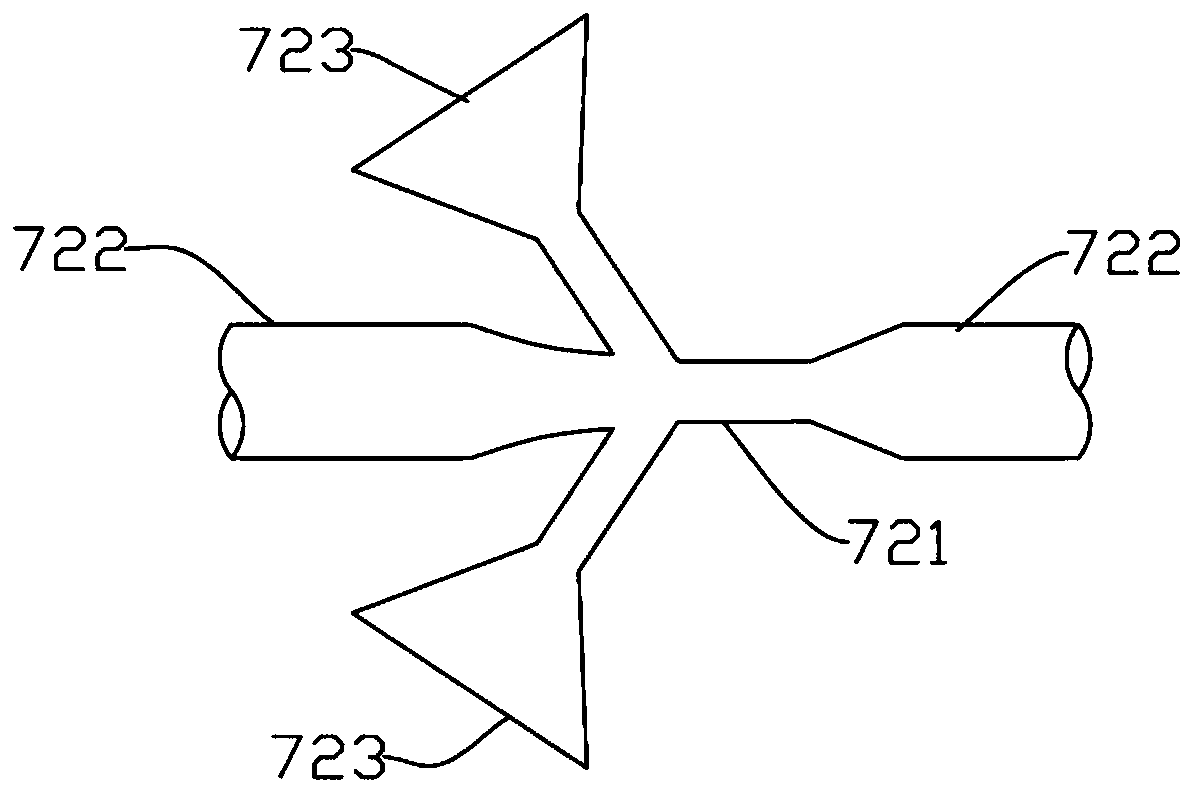

[0028] combine Figure 1 to Figure 4 As shown, the sludge co-combustion system of the present invention is schematically shown, including the gas transmission assembly 1 and the sludge silo 2, feeder 3, sludge crusher 4, weighing bin 5 and Delivery bin 6. The weighing bin 5 is provided with a load cell 51 for weighing the sludge inside. One end of the load cell 51 is connected to the weighing bin 5 and the other end is connected to the building structure for carrying the system. The discharge end of the delivery bin 6 is connected to the boiler furnace through a delivery pipe. The air delivery assembly 1 includes an air source 11 , a first air intake valve 12 and a seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com