Rock core inner tube salvager of submarine drilling rig rope coring drilling tool

A wireline coring and overshot technology, which is applied in the direction of extracting undisturbed core devices, earthwork drilling, wellbore/well components, etc., can solve the problems of very high automation requirements, manual auxiliary operations, complex structures, etc., and achieve low cost , Convenient operation, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

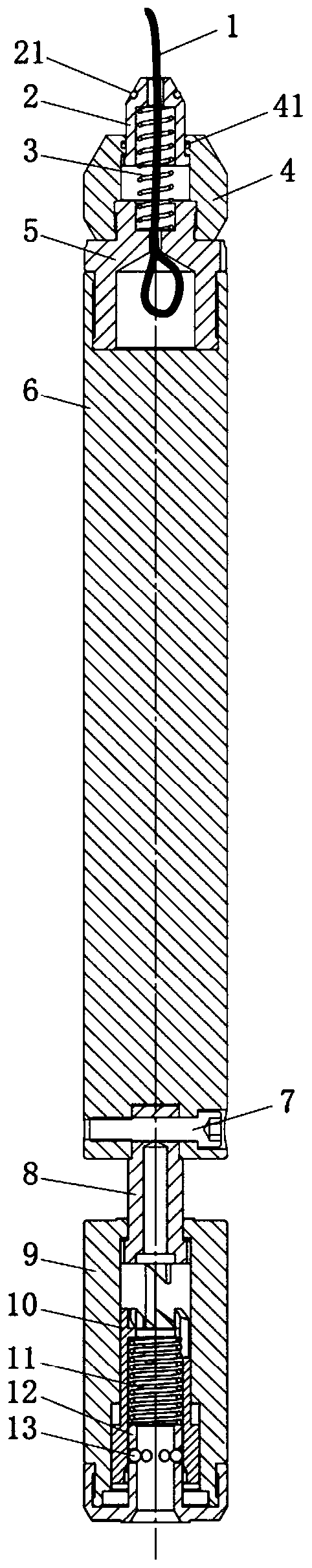

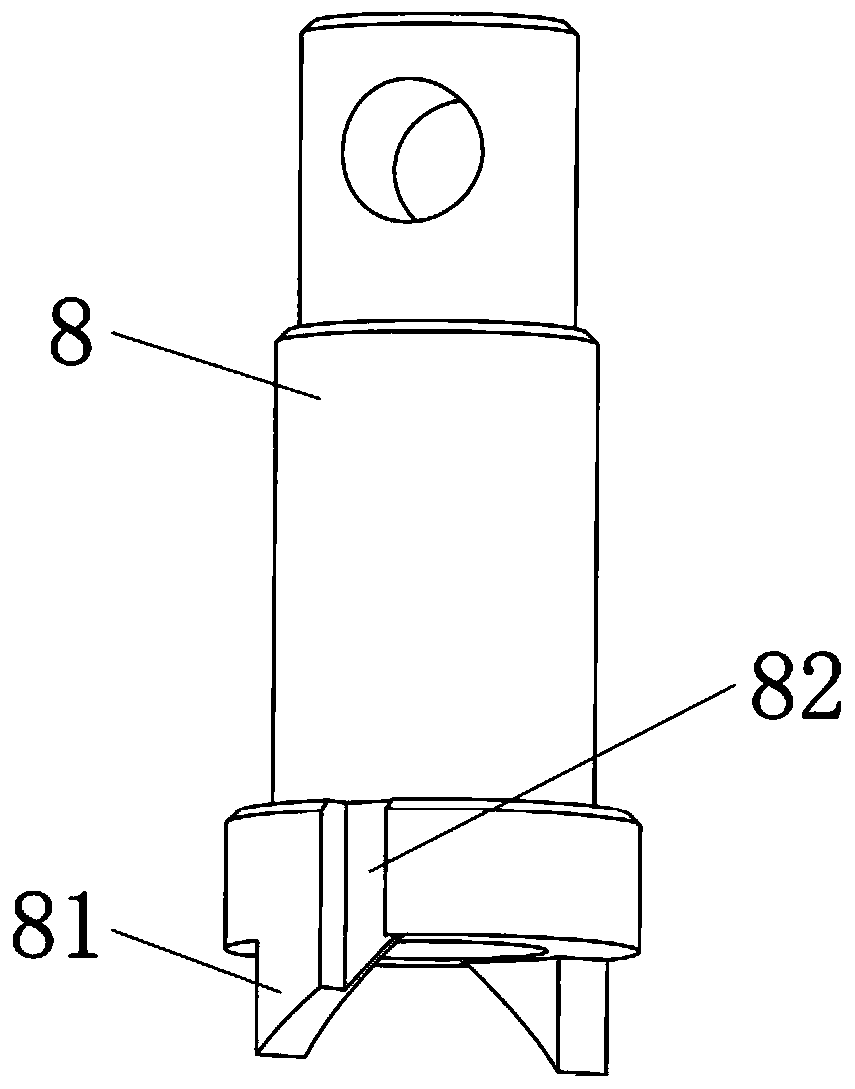

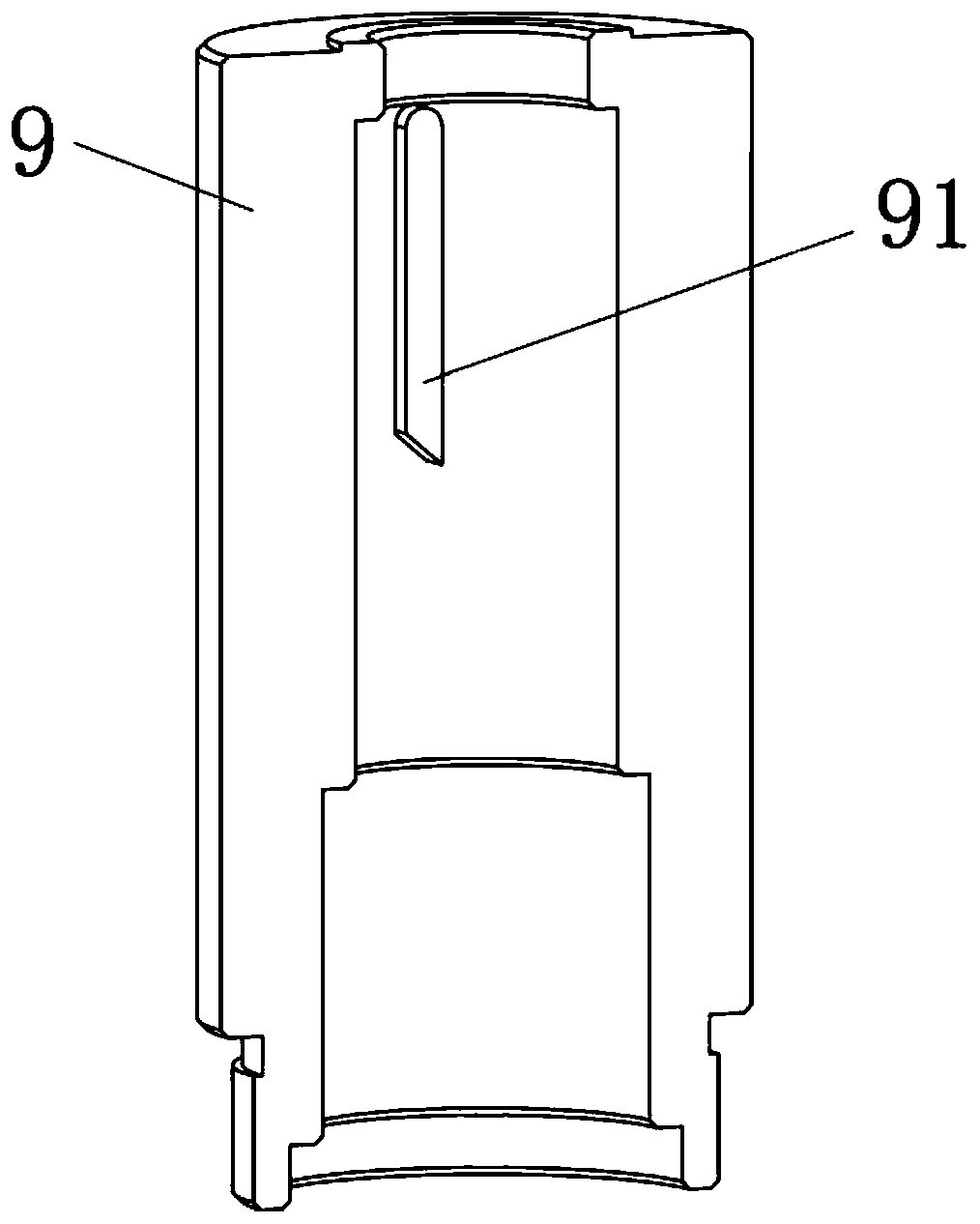

[0022] Such as figure 1 As shown, the present invention includes a fishing wire rope 1, an anti-jamming mechanism, a weight rod 6, a pressure rod 8, a fixed guide tube 9, a swivel ferrule 10, a compression spring 11, a steel ball seat 12 and a steel ball 13. The anti-jamming mechanism includes a sealing head 2, an anti-jamming spring 3, a connecting pipe 4, a sealing ring II 41 and a hanger 5, the hanger 5 is fixed on the upper end of the weight rod 6, and the hanger 5 and the fishing wire rope 1 is connected at one end. The suspension head 5 is connected to the lower end of the connecting pipe 4, the lower end of the sealing head 2 is placed in the connecting pipe 4, the lower end of the sealing head 2 is provided with a flange, and the diameter of the flange is larger than the diameter of the through hole at the top of the connecting pipe 4, which can prevent the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com