Steel hoop structure for additionally arranging steel cover beam on pier stand column and installing method

An installation method and technology of steel cover beams, which are applied in the direction of bridges, bridge parts, bridge materials, etc., can solve the problems of weak bonding force of organic glue, impossible to achieve close adhesion, and discounted bonding effect, so as to increase the bonding force. Effect, easy to promote and use, reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

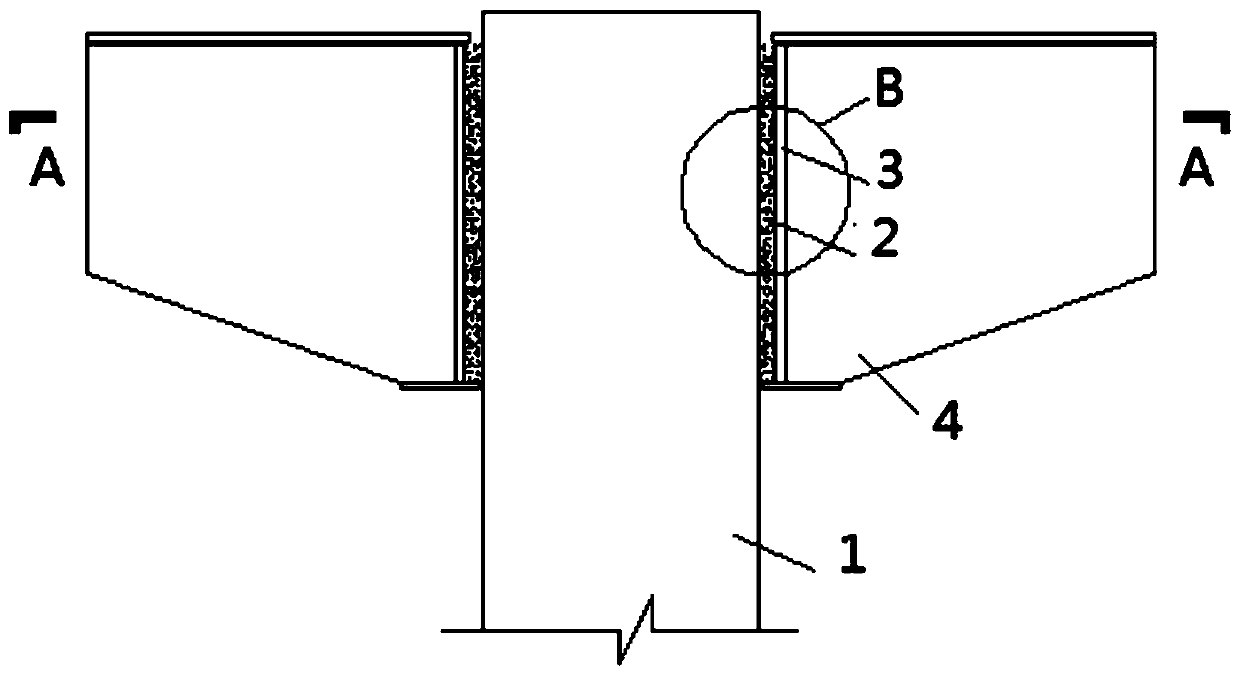

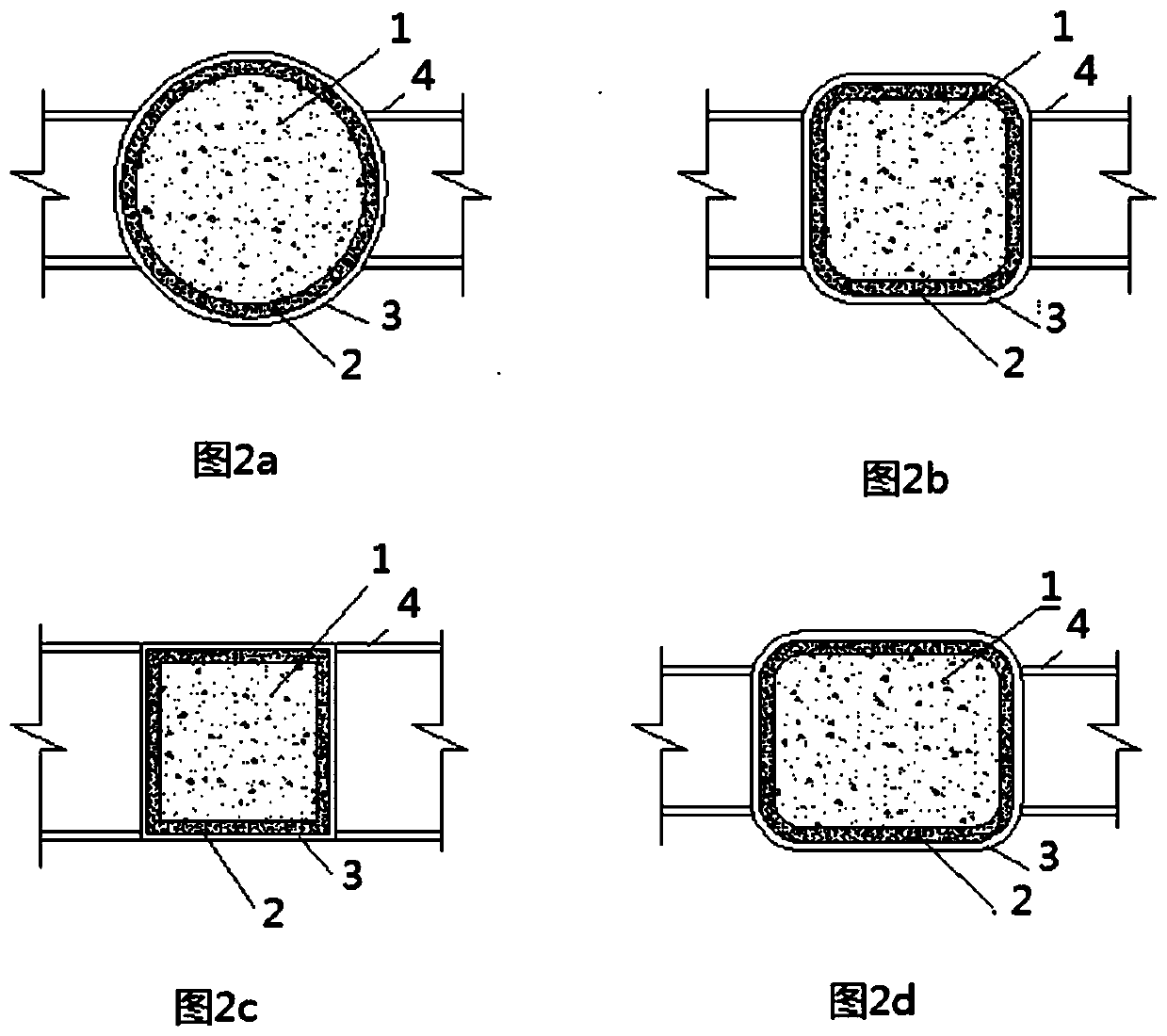

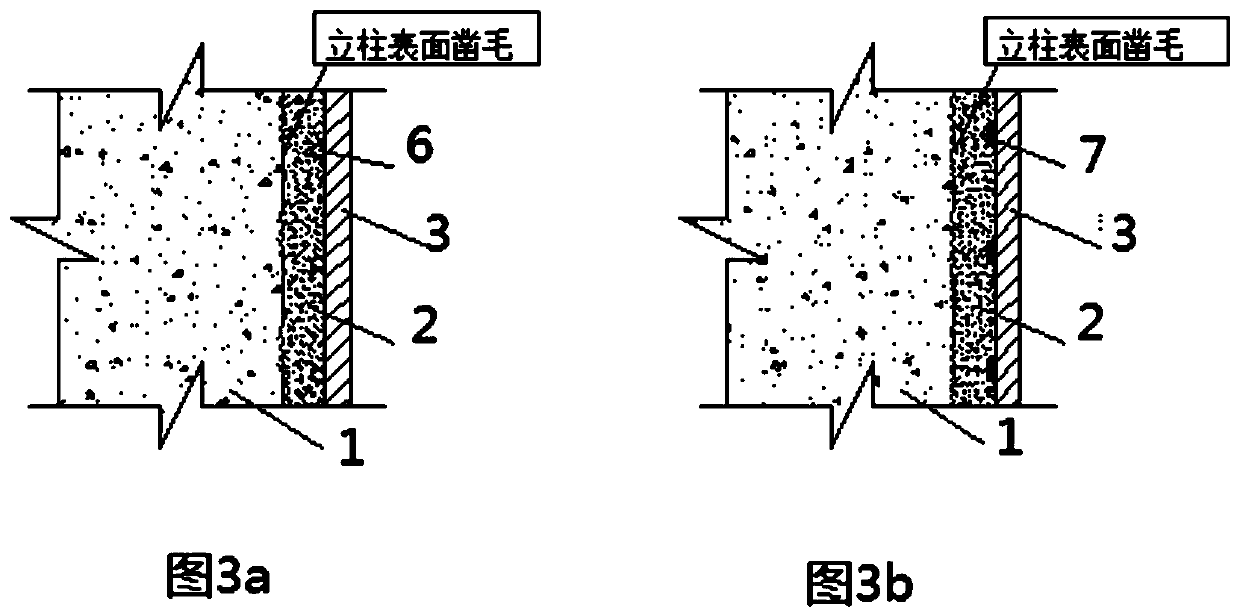

[0020] The invention provides a steel hoop structure for adding a steel cover beam to a pier column. For details, see figure 1 , which includes a concrete column, and its difference from the prior art is that a steel sleeve is arranged around the concrete column, a gap is provided between the steel sleeve and the concrete column, and a cement mortar layer is provided in the gap, so that the steel sleeve forms a steel cage. One or more outwardly extending steel members are arranged outside the steel hoop to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com