Raw material stirring tank for PVC pipe machining

A PVC pipe and mixing tank technology, applied in the field of raw material mixing tanks for PVC pipe processing, can solve the problems of low mixing efficiency, affecting product quality, and insufficient mixing, and achieve the effect of improving quality and improving mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

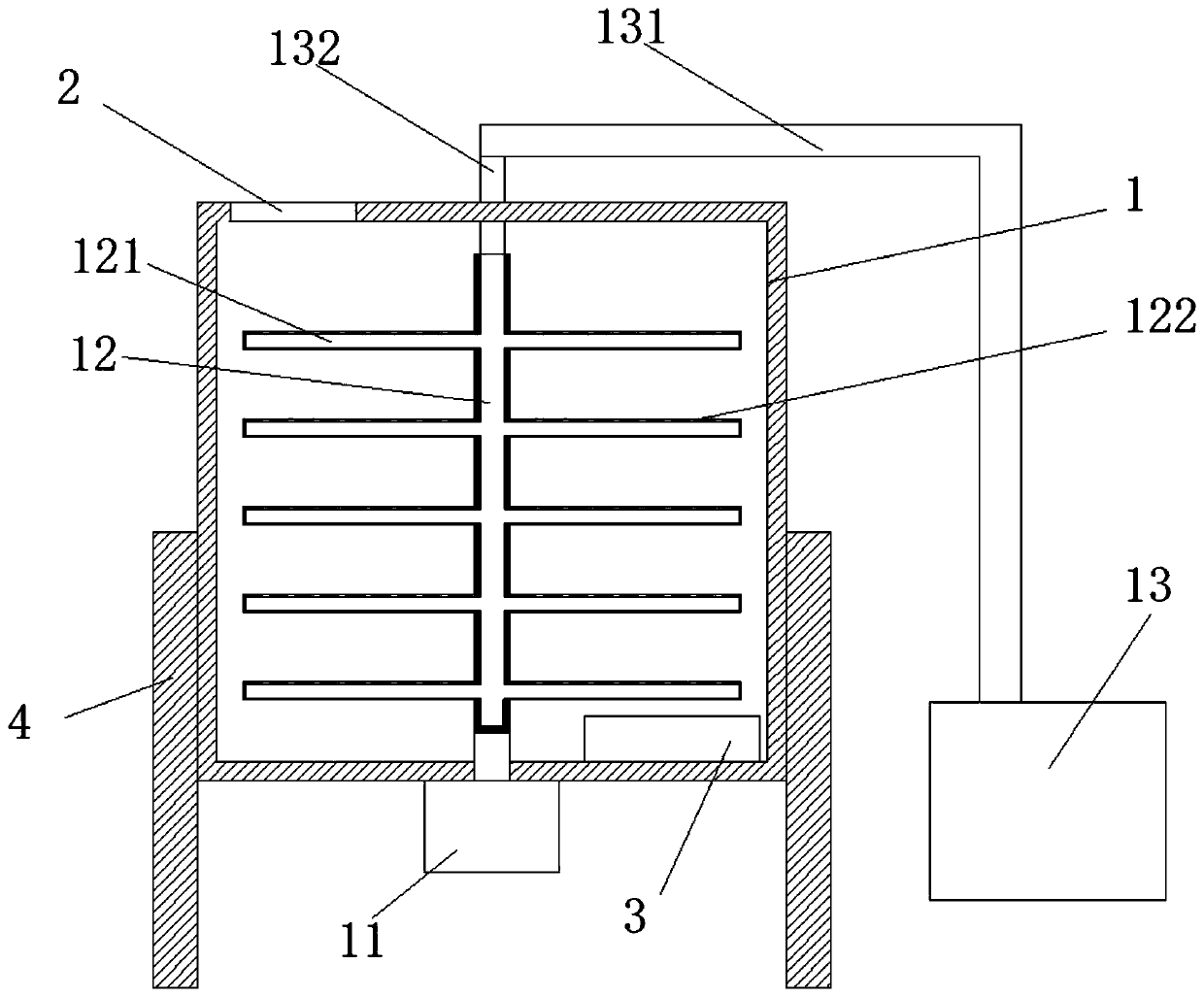

[0022] see figure 1 , a raw material stirring tank for PVC pipe processing, comprising a tank body 1, a rotatable stirring shaft 12 is arranged in the middle of the tank body 1, and ten stirring rods 121 fixedly connected are arranged on the stirring shaft 12, so that Both the stirring shaft 12 and the stirring rod 121 are provided with hollow tanks, and the hollow tanks between the stirring shaft 12 and the stirring rod 121 are connected to each other, and the stirring rod 121 is provided with a plurality of one-way aeration holes 122 , the outside of the tank body 1 is provided with an aerator 13, the output end of the aerator 13 is provided with an aeration pipe 131, and the upper end of the stirring shaft 12 is provided with a hollow tank connected to the uppermost stirring shaft 12. The connecting pipe 132 , the extension end of the connecting pipe 132 passes through the tank body 1 and communicates with the aeration pipe 131 .

[0023] The design of the hollow stirring ...

Embodiment 2

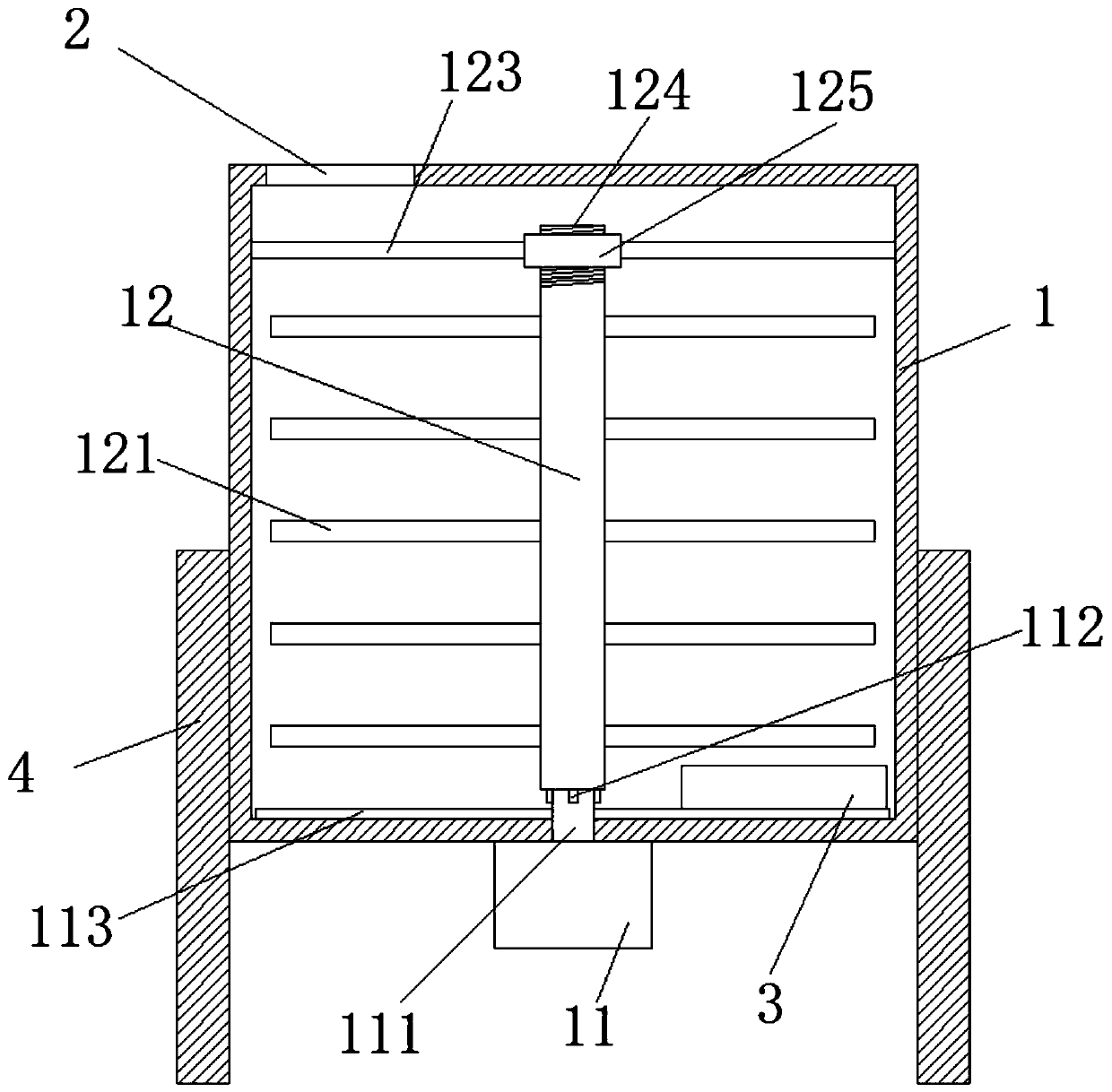

[0027] see Figure 2-4 , a raw material stirring tank for PVC pipe processing, comprising a tank body 1, a rotatable stirring shaft 12 is arranged in the middle of the tank body 1, and ten stirring rods 121 fixedly connected are arranged on the stirring shaft 12, so that A stirring motor 11 is provided at the center of the bottom of the tank body 1, and the stirring motor 11 drives the stirring shaft 12 to rotate;

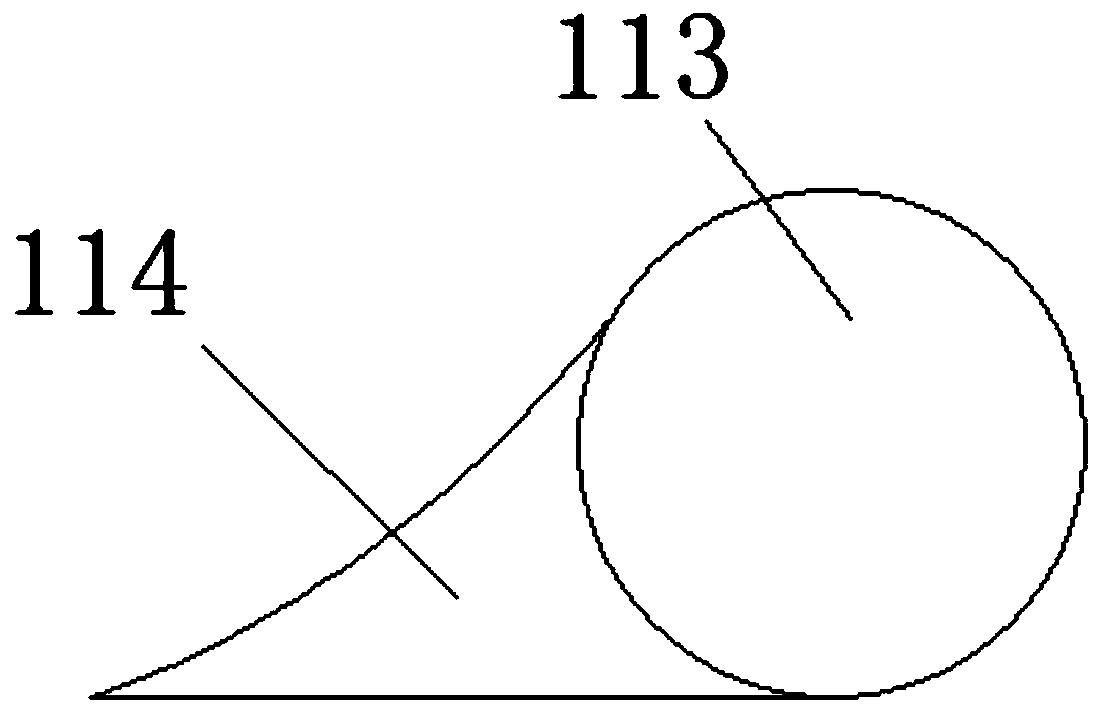

[0028] Further, the output end of the stirring motor 11 is provided with an output shaft 111, and the output shaft 111 moves through the bottom of the tank body 1, and the bottom of the stirring shaft 12 is provided with a connecting groove 128 which is movably connected with the output shaft 111, and is located at The output shaft 111 in the tank body 1 is provided with four fixedly connected limiting blocks 112, and the side wall of the connecting groove 128 is provided with four limiting grooves 126 matched with the limiting blocks 112; The outer wall of the up...

Embodiment 3

[0039] see Figure 5 , a raw material stirring tank for PVC pipe processing, comprising a tank body 1, a rotatable stirring shaft 12 is arranged in the middle of the tank body 1, and ten stirring rods 121 fixedly connected are arranged on the stirring shaft 12, so that Both the stirring shaft 12 and the stirring rod 121 are provided with hollow tanks, and the hollow tanks between the stirring shaft 12 and the stirring rod 121 are connected to each other, and the stirring rod 121 is provided with a plurality of one-way aeration holes 122 , the outside of the tank body 1 is provided with an aerator 13, the output end of the aerator 13 is provided with an aeration pipe 131, and the upper end of the stirring shaft 12 is provided with a hollow tank connected to the uppermost stirring shaft 12. The connecting pipe 132 , the extension end of the connecting pipe 132 passes through the tank body 1 and communicates with the aeration pipe 131 .

[0040] Further, the upper end of the tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com