A wet sand blasting device

A sandblasting device and sandblasting technology, applied in the direction of abrasive feeding device, used abrasive processing device, abrasive jetting machine tool, etc., can solve the difficulty of sandblasting large workpieces, secondary cleaning of workpieces, cumbersome recycling process, etc. problems, to achieve the effect of convenient recovery and recycling, easy placement and flipping, and convenient sandblasting operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

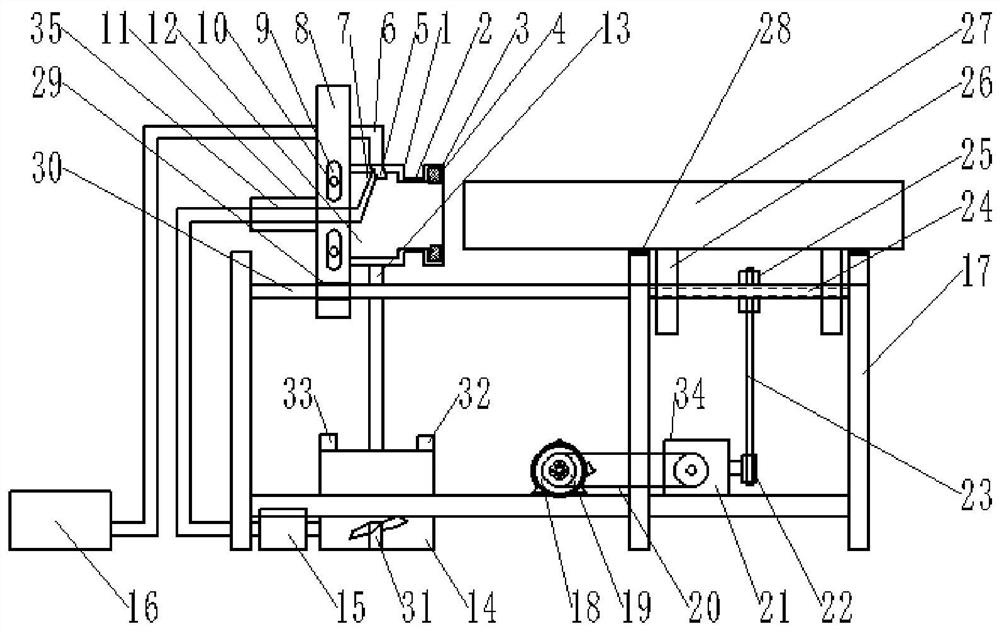

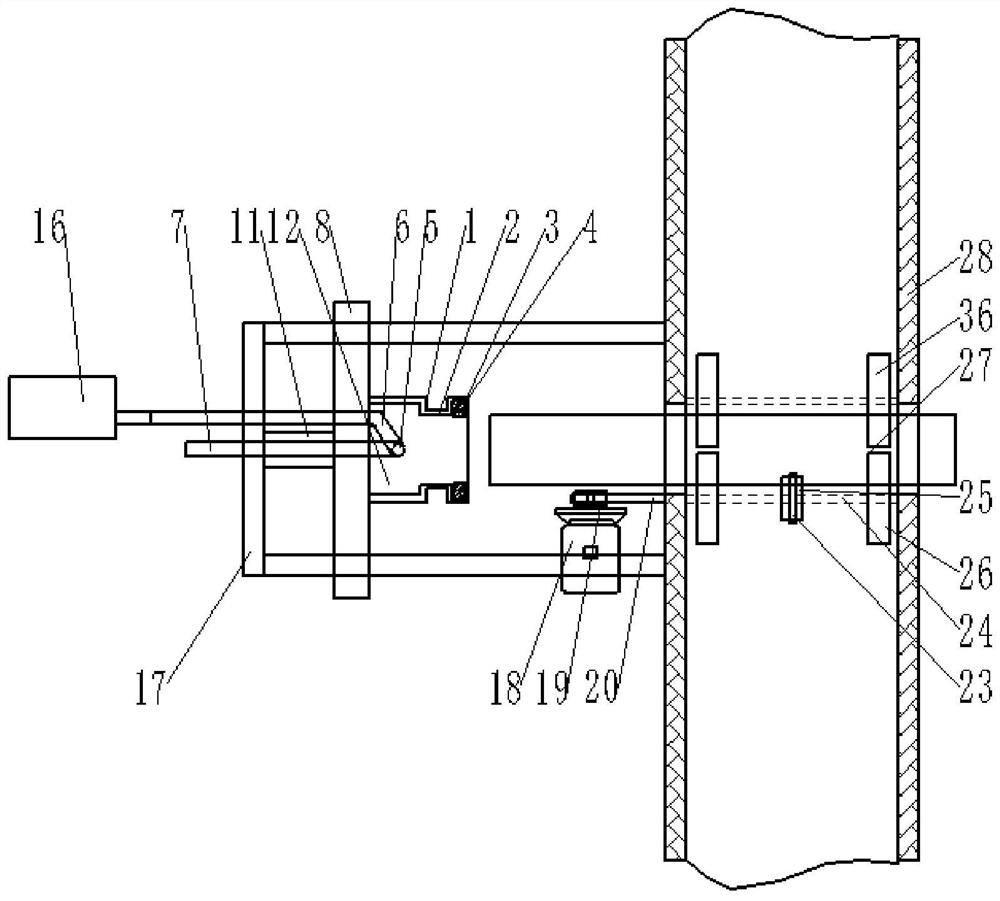

[0047] like figure 1 and figure 2 As shown, the present invention provides a wet sandblasting device comprising:

[0048] Sandblasting shell 1, a shell mounting bracket 8 is arranged behind the sandblasting shell 1, the shell mounting bracket 8 is mounted on one side of the frame 17, and a nozzle is arranged above the interior of the sandblasting shell 1 5. The upper end of the nozzle 5 is connected with a compressed air pipe 6, the other end of the compressed air pipe 6 is connected with an air compressor 16, one side of the nozzle 5 is connected with a mortar conveying pipe 7, and the other end of the mortar conveying pipe 7 is connected A grinding liquid pump 15 is connected, the other end of the grinding liquid pump 15 is connected with a mortar storage tank 14, a mortar recovery pipe 13 is arranged on the lower side of the sandblasting shell 1, and the lower end of the mortar recovery pipe 13 is connected to the mortar storage tank 14 top;

[0049] The workpiece loadi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com