Copper-contained composite hydrogen storage alloy and preparation method for same, composite solid-state hydrogen storage tank, and hydrogen storage-discharge performance testing method

A technology of hydrogen storage alloy and testing method, applied in fixed-capacity gas storage tanks, hydrogen technology, mechanical equipment, etc., can solve problems such as deformation of hydrogen storage tanks, safety accidents, cracking damage, etc., and achieve good safety and fast heat transfer rate. , the effect of high hydrogen storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

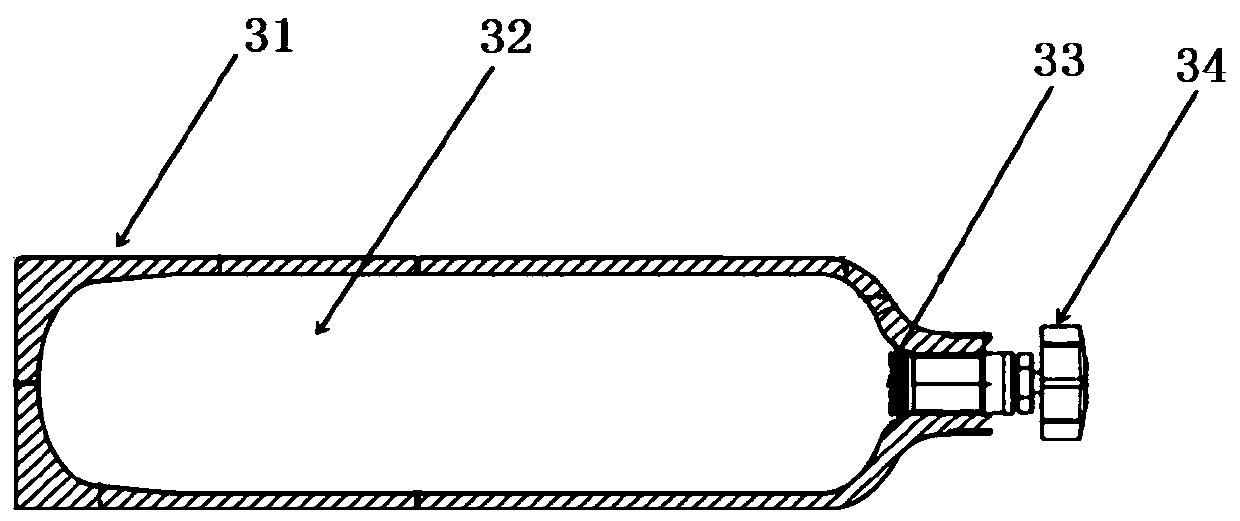

[0041] The preparation steps of hydrogen storage alloy powder: specifically include melting raw materials to prepare hydrogen storage alloy ingots, and then performing vacuum annealing homogenization treatment on the alloy ingots, the temperature of the melting is 1300 ° C ~ 1500 ° C The temperature of the homogenization treatment is 800-1150° C., and the annealing time is 5-10 hours; then, the annealed hydrogen storage alloy ingot is broken into small ingots, and ball milled to obtain the hydrogen storage alloy powder with a particle size of 75-300 μm.

[0042] Prepare copper material;

[0043] When the copper material is atomized copper powder, the atomized copper powder is spherical particles with a particle size of μm order, and the purity is preferably 99.85% to 99.9%; more preferably, the particle size of the atomized copper powder is 1-300 μm, It is further preferably 1-100 μm; when the copper material is electrolytic copper powder, the electrolytic copper powder is a d...

Embodiment 1

[0069] Prepare copper material: select 1-50 μm atomized copper powder as the copper material.

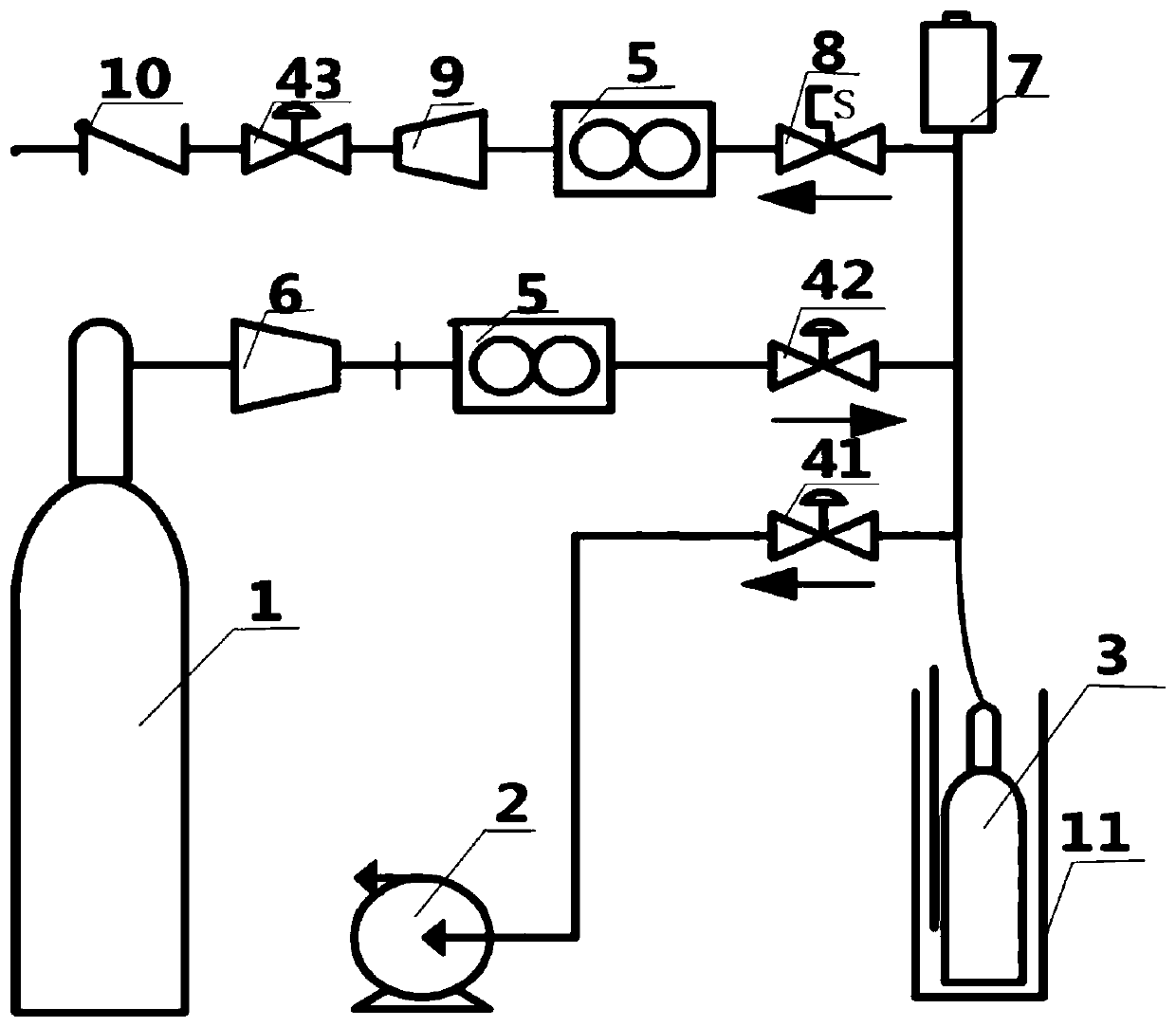

[0070]Preparation of composite hydrogen storage alloy powder: take 3200g of the above hydrogen storage alloy powder, 565g of atomized copper powder, the copper powder accounts for 15% of the total mass of the composite material, mix the two with a mixer, the mixing time is 2h, and then fill the composite material In the hydrogen storage tank, the composite hydrogen storage alloy powder accounts for about 80% of the volume of the hydrogen storage tank. Charge hydrogen and activate the composite hydrogen storage alloy powder in the hydrogen storage tank: install the hydrogen storage tank on the hydrogen storage tank hydrogen charging and activation treatment device, put the hydrogen storage tank in the heating jacket, and control the temperature at 90°C. Connect with the vacuum pump, open the ball valve and vacuum pump, pump out the air in the hydrogen storage tank for 6 hours, then f...

Embodiment 2

[0074] Prepare the copper material: select electrolytic copper powder with a particle size of 1-50 μm as the copper material.

[0075] Preparation of composite hydrogen storage alloy powder: take 3200g of the above hydrogen storage alloy powder, weigh 565g of electrolytic copper powder, copper powder accounts for 15% of the total mass of the composite material, mix the two with a mixer, and the mixing time is 2h, and then the composite material Filled into the hydrogen storage tank, the composite hydrogen storage alloy powder accounts for about 80% of the volume of the hydrogen storage tank.

[0076] Charge hydrogen and activate the composite hydrogen storage alloy powder in the hydrogen storage tank: install the hydrogen storage tank on the hydrogen storage tank hydrogen charging and activation treatment device, put the hydrogen storage tank in the heating jacket, and control the temperature at 90°C. Connect with the vacuum pump, open the ball valve and vacuum pump, pump out ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com