System and method for preventing continuous casting secondary cooling nozzle from being blocked

A nozzle and continuous casting technology, which is applied in the field of the system to prevent the blockage of the secondary cooling nozzle of continuous casting, can solve the problems of scaling and blockage of the nozzle, and achieve the effect of improving the utility period, ensuring the uniformity and reducing the maintenance cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

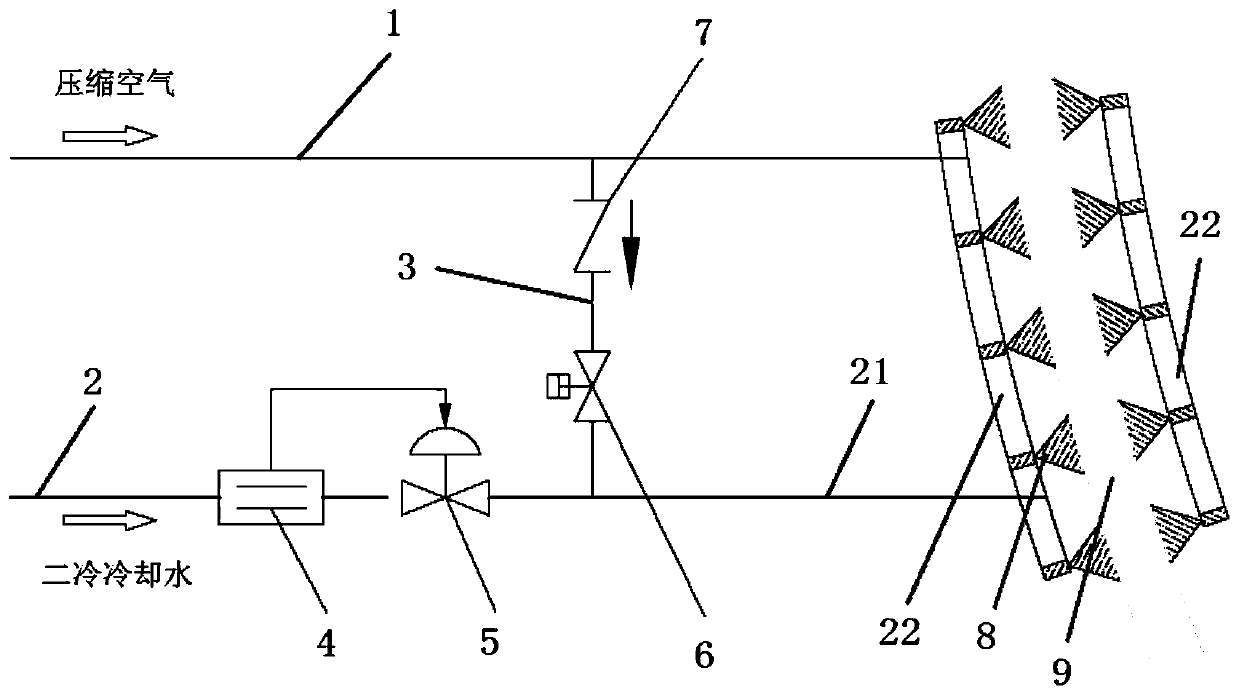

[0025] Such as figure 1 As shown, this embodiment provides a system for preventing the clogging of the continuous casting secondary cooling nozzle, including a compressed air pipeline 1, a secondary cooling water pipeline 2, and the secondary cooling water pipeline 2 includes a main pipe 21 and several uniformly distributed around the casting slab The main pipe 21 is provided with an electromagnetic flowmeter 4 and a pneumatic flow regulating valve 5 in sequence along the flow direction of the secondary cooling water. The branch pipe 22 is provided with a number of nozzles 8 uniformly distributed around the casting slab 9, compressed air An intermediate pipeline 3 communicating with the pipeline 1 and the secondary cooling water pipeline 2 is arranged, and the communication position between the intermediate pipeline 3 and the secondary cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com