Automatic preparation equipment for building putty

An automatic configuration, putty technology, applied in mixer accessories, mixers with rotary mixing devices, mixers, etc., can solve the problems of uneven mixing and large labor, and achieve the effect of easy operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

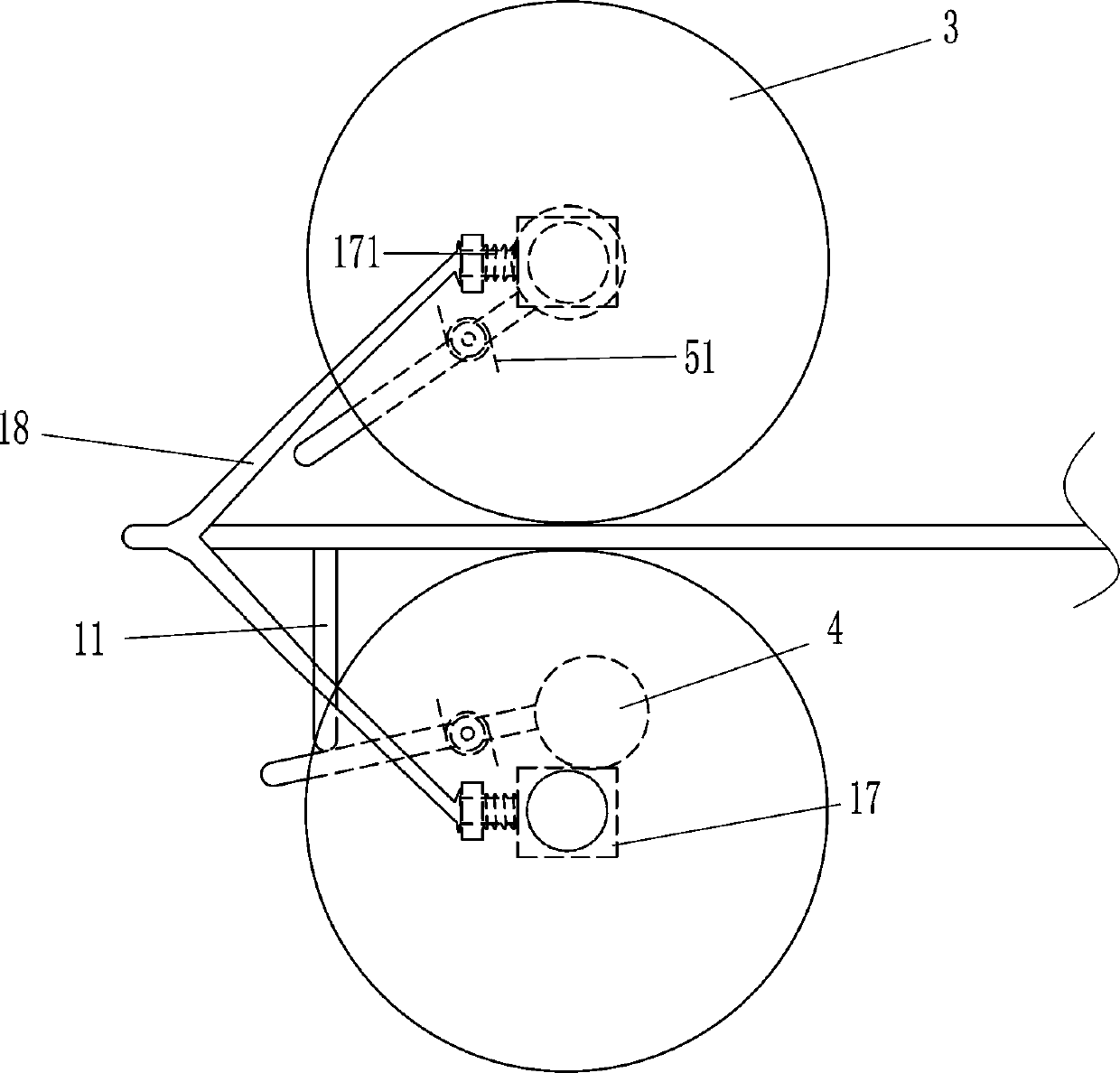

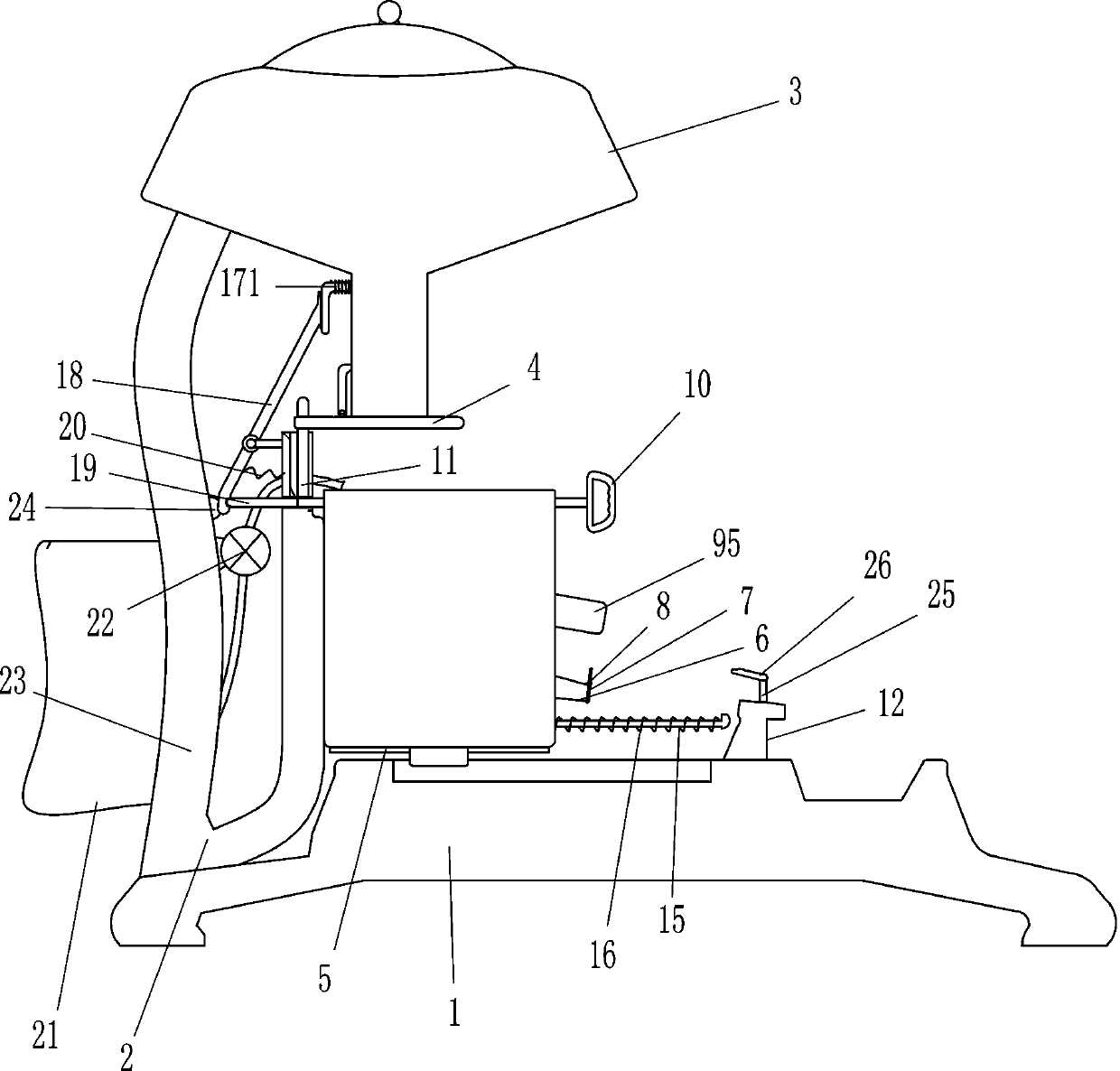

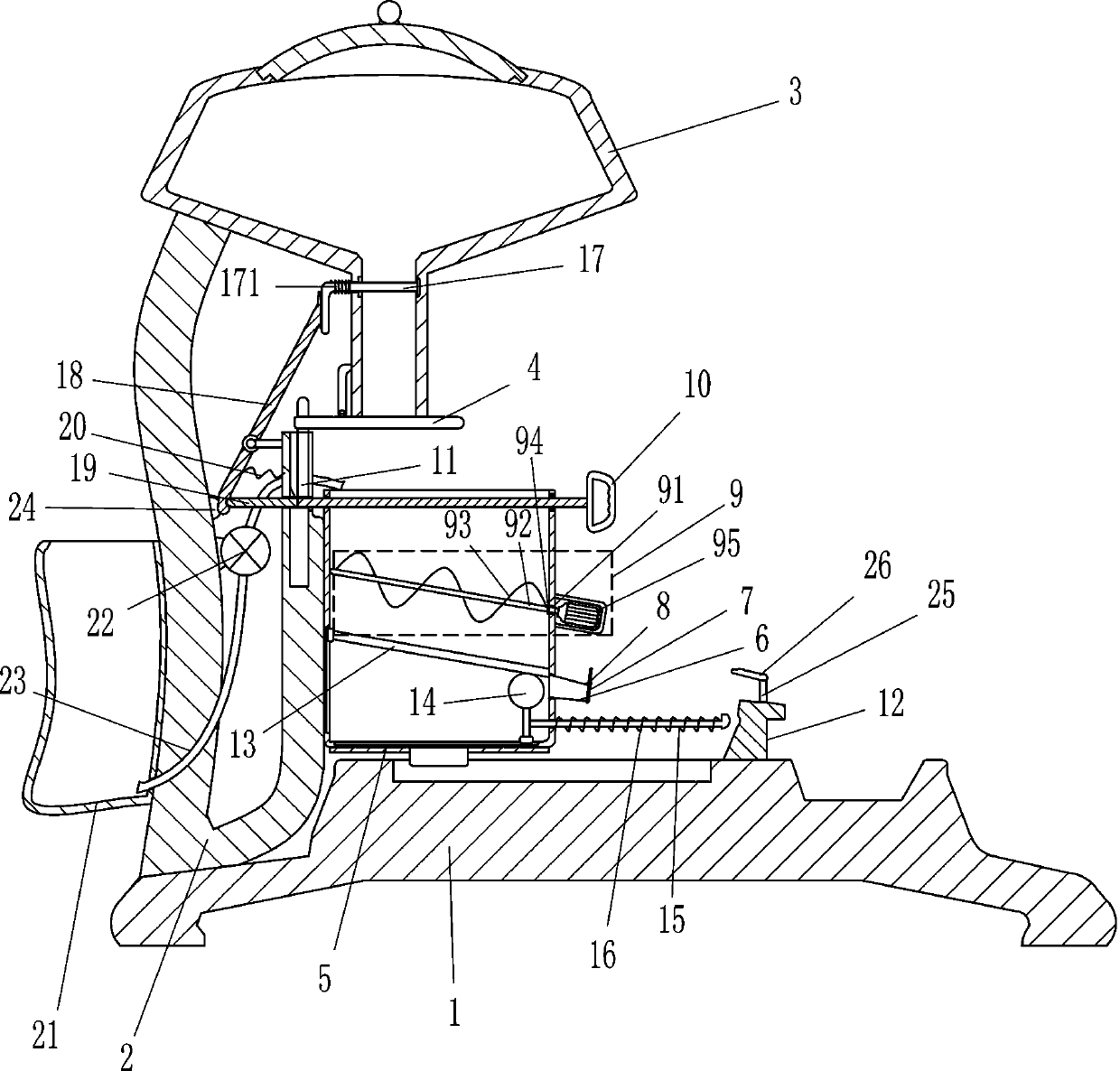

[0017] A building putty automatic configuration device such as Figure 1-3 As shown, it includes a support 1, a frame 2, a material box 3, a baffle plate 4, a mixing box 5, a torsion spring 51, a discharge pipe 6, a baffle plate 7, a first elastic member 8, a stirring device 9, and a pull rod 10. Toggle block 11, stop block 12, slide plate 13, top block 14, ejector rod 15 and second elastic member 16, frame 2 is set on the top of support 1, and material box is set on frame 2 through bolt connection 3. The number of the material box 3 is 2, and the baffle plate 4 is arranged on the discharge port of the material box 3 in a rotating manner, and a torsion spring 51 is arranged between the material baffle plate 4 and the discharge port, and the frame 2 slides A mixing box 5 is arranged on the mixing box 5, and a discharge pipe 6 is arranged on the mixing box 5. On the discharge pipe 6, a baffle plate 7 is rotatably arranged, and a first elastic member 8 is arranged between the baf...

Embodiment 2

[0021] Such as Figure 1-3 As shown, on the basis of Embodiment 1, it also includes a moving plate 17, a third elastic member 171, a special-shaped rod 18, a connecting rod 19 and a fourth elastic member 20, and a sliding movement is provided on the outlet of the material box 3. Plate 17, a third elastic piece 171 is arranged between the moving plate 17 and the discharge port of the material box 3, and the third elastic piece 171 is a compression spring. On the left side of 17, a connecting rod 19 is arranged on the tie rod 10 by welding, and a fourth elastic member 20 is arranged between the special-shaped rod 18 and the frame 2, and the fourth elastic member 20 is a tension spring.

[0022] When quantitative feeding of gypsum powder and white cement is required, first push the pull rod 10 to the left, the pull rod 10 pushes the special-shaped rod 18 to move to the left through the connecting rod 19, the lower part of the special-shaped rod 18 swings to the left, and the four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com