Preparation method and application of multifunctional biomass wrinkle resisting and removing agent

A biomass, multi-functional technology, applied in the field of daily chemicals, can solve problems such as toxicity, and achieve the effect of wrinkle smoothing, wrinkle prevention and anti wrinkle performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Add 0.5 part of alkyl polyglycoside quaternary ammonium salt, 0.75 part of sucrose fatty acid ester quaternary ammonium salt, 0.75 part of starch ether base quaternary ammonium salt, 0.25 part of rosemary essential oil, 0.75 part of ylang ylang essential oil, lavender After 0.4 parts of essential oil, 0.6 parts of ginger essential oil, 35 parts of deionized water, 5 parts of ethanol, and 2.5 parts of glycerin, use a homogenizer to homogenize at 6500 rpm for 8 minutes. 0.75 parts of ammonium salt, 1.125 parts of sucrose fatty acid ester quaternary ammonium salt, 1.125 parts of starch ether base quaternary ammonium salt, 1.75 parts of guar gum, 1.25 parts of gum arabic, 40 parts of deionized water, 5 parts of ethanol, 2.5 parts of glycerin, and use The homogenizer was homogenized at 3600 rpm for 15 minutes to obtain a translucent microemulsion, which is a multifunctional biomass anti-wrinkle and anti-wrinkle agent.

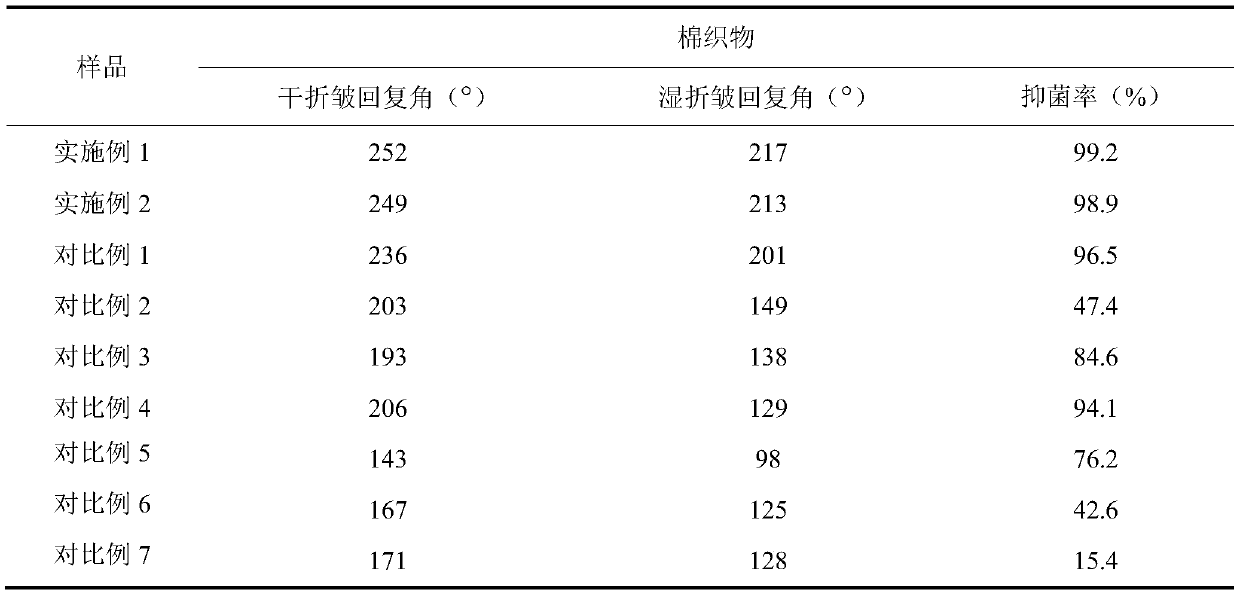

[0039]Test results: the wrinkle recovery angles of cott...

Embodiment 2

[0041] Add 0.6 parts of alkyl polyglycoside quaternary ammonium salt, 0.65 part of sucrose fatty acid ester quaternary ammonium salt, 0.5 part of starch ether base quaternary ammonium salt, 0.5 part of rosemary essential oil, 0.75 part of ylang-ylang essential oil, lavender After 0.25 parts of essential oil, 0.75 parts of ginger essential oil, 35 parts of deionized water, 5 parts of ethanol, and 2.5 parts of glycerin, use a homogenizer to homogenize at 6500 rpm for 8 minutes. After obtaining a clear solution, continue to add alkyl polyglycosides in sequence. 0.75 parts of ammonium salt, 1.125 parts of sucrose fatty acid ester quaternary ammonium salt, 1.125 parts of starch ether base quaternary ammonium salt, 2 parts of guar gum, 1 part of gum arabic, 40 parts of deionized water, 5 parts of ethanol, 2.5 parts of glycerin, and use The homogenizer was homogenized at 3600 rpm for 15 minutes to obtain a translucent microemulsion, which is a multifunctional biomass anti-wrinkle and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com