Building concrete mixing device

A kind of mixing equipment and concrete technology, which is applied in the direction of clay preparation equipment, cement mixing equipment, unloading equipment, etc., which can solve the problems of low mixing uniformity and inconvenient unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

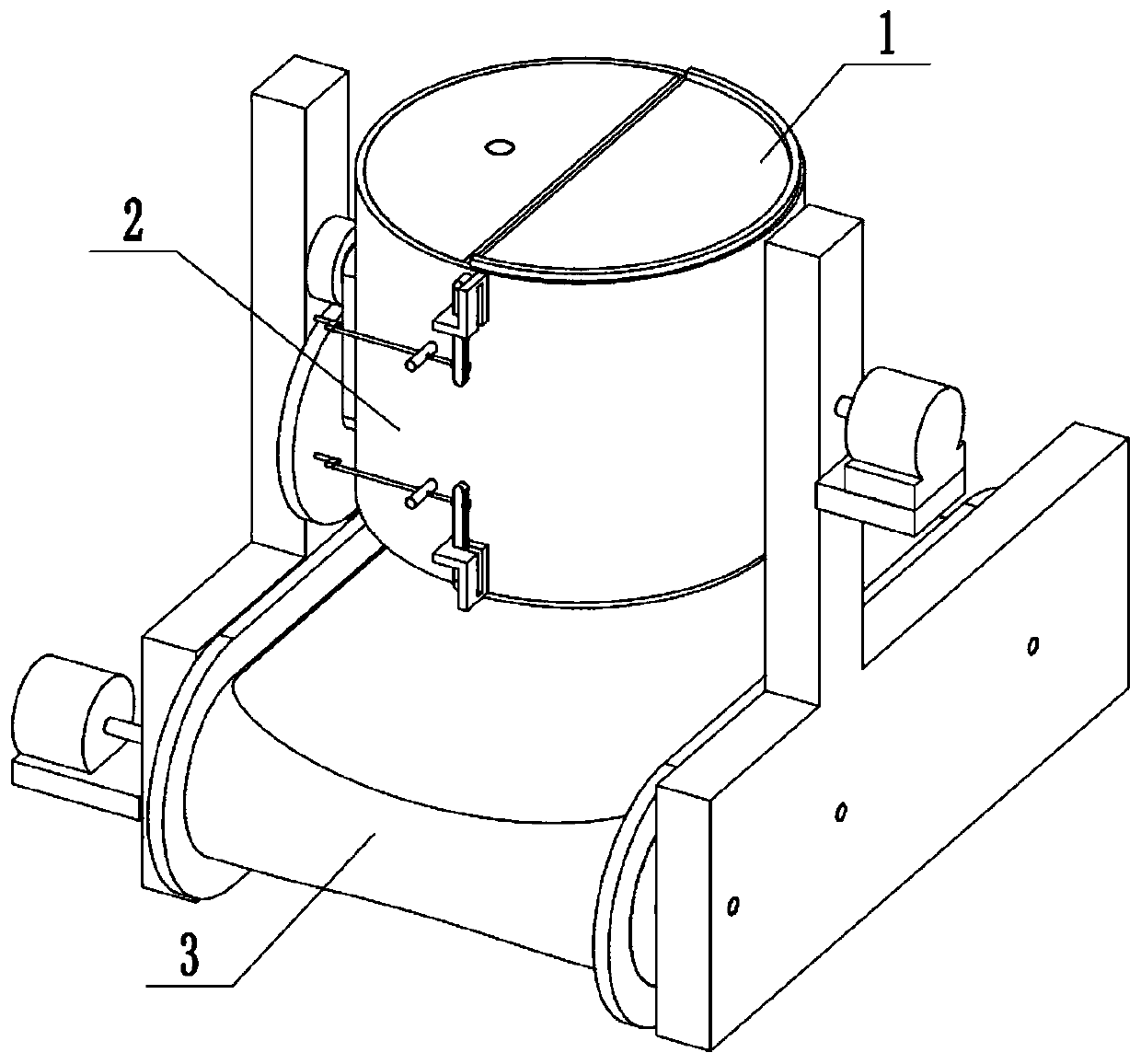

[0026] Combine below Figure 1-12 In this embodiment, a construction concrete mixing equipment includes a mixing chamber assembly 1, a stirring assembly 2 and a discharge assembly 3, the mixing chamber assembly 1 is connected to the stirring assembly 2, and the stirring assembly Body 2 is connected to discharge assembly body 3.

specific Embodiment approach 2

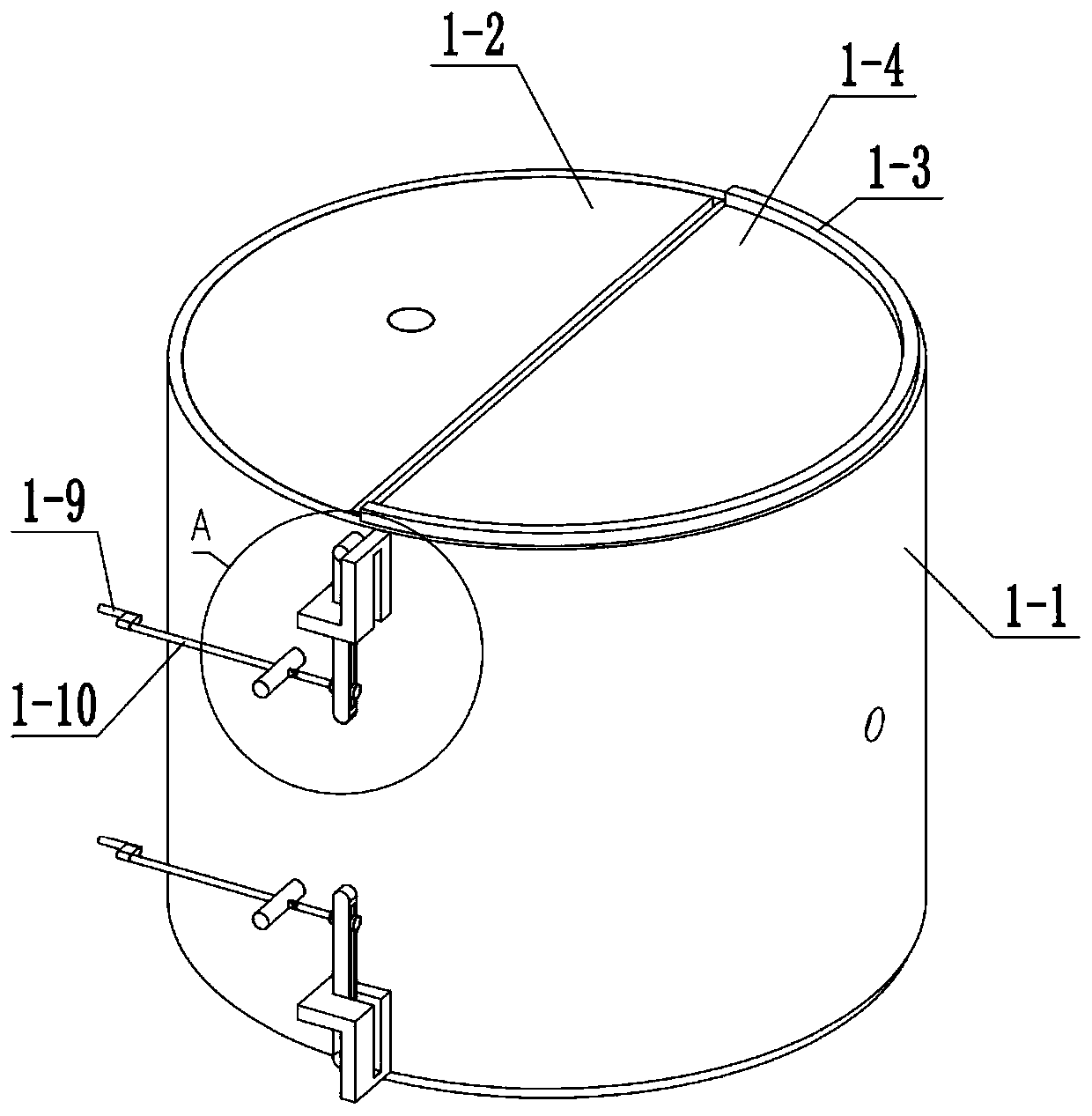

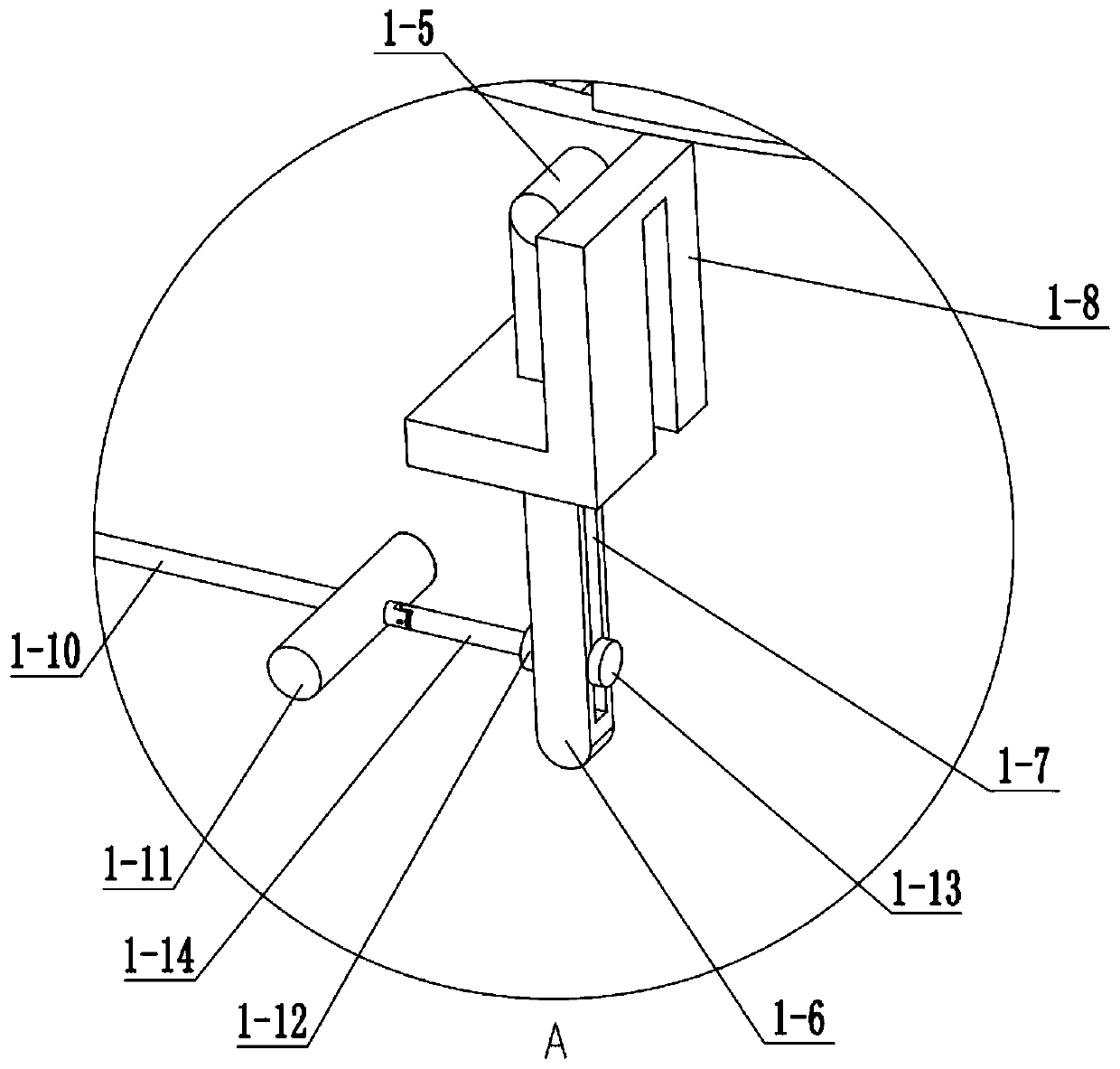

[0028] Combine below Figure 1-12 This embodiment, this embodiment will further explain Embodiment 1. The mixing chamber assembly 1 includes a stirring chamber 1-1, a stirring fixed cover 1-2, a sealing strip 1-3, a semicircular rotating cover 1-4, a rotating Cover shaft 1-5, rotating rod 1-6, rotating rod groove 1-7, rotating rod limit slide rail 1-8, rocker 1-9, threaded shaft 1-10, threaded rotating column 1-11, push block 1-12, pulling block 1-13 and hinge rod 1-14, the mixing chamber 1-1 is connected with two stirring fixed covers 1-2, and the two stirring fixed covers 1-2 are respectively connected with two semicircular rotary covers 1- 4-phase contact, the two semicircular rotary covers 1-4 are respectively connected with the two sealing strips 1-3, the two semicircular rotary covers 1-4 are respectively connected with the two rotary cover shafts 1-5, and the two rotary cover shafts 1-5 are rotationally connected with the mixing chamber 1-1, the two rotary cover shafts...

specific Embodiment approach 3

[0030] Combine below Figure 1-12This embodiment, this embodiment will further explain the first embodiment, the stirring assembly 2 includes the motor I 2-1, the motor I bracket 2-2, the pillar 2-3, the support plate 2-4, the motor I shaft 2- 5. Bevel gear Ⅰ2-6, bevel gear Ⅱ2-7, bevel gear Ⅲ2-8, bevel gear shaft Ⅰ2-9, bevel gear shaft Ⅱ2-10, bevel gear shaft Ⅲ2-11, bevel gear shaft Ⅳ2-12, spiral blade 2-13, sun gear 2-14, connecting rod 2-15, planetary gear fixed shaft 2-16, planetary gear 2-17, transmission housing Ⅰ 2-18, connecting sleeve 2-19 and transmission housing Ⅱ 2-20, motor Ⅰ 2-1 is connected with the motor Ⅰ support 2-2, the motor Ⅰ support 2-2 is connected with the pillar 2-3, the two pillars 2-3 are respectively connected with the two support plates 2-4, the motor Ⅰ 2-1 is connected with the The motor I shaft 2-5 is connected, the motor I shaft 2-5 is connected to the pillar 2-3 in rotation, the motor I shaft 2-5 is connected to two bevel gears I2-6, and the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com