Circular glass corner intelligent polishing device

A polishing device and glass technology, applied in the direction of grinding/polishing equipment, machine tools suitable for grinding the edge of workpieces, cleaning methods and tools, etc., can solve the problems of poor grinding effect, achieve uniform coating and prevent waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Various exemplary embodiments of the present invention are now described in detail, which should not be construed as limitations of the invention, but rather as more detailed descriptions of certain aspects, features, and embodiments of the invention.

[0032] It will be apparent to those skilled in the art that various modifications and changes can be made in the specific embodiments of the present invention described herein without departing from the scope or spirit of the present invention. Other embodiments will be apparent to the skilled person from the description of the present invention. The specification and examples in this application are exemplary only.

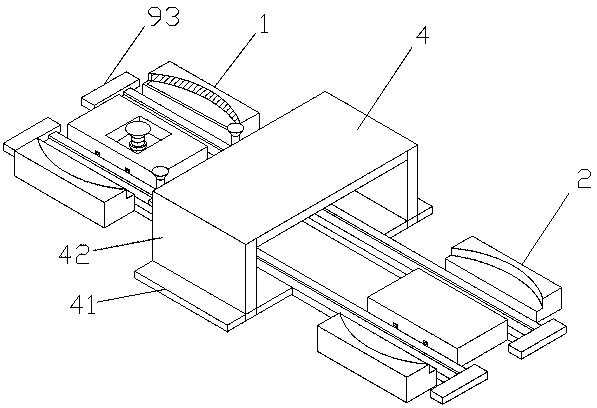

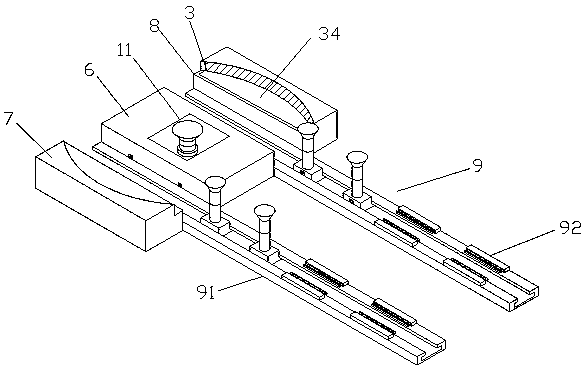

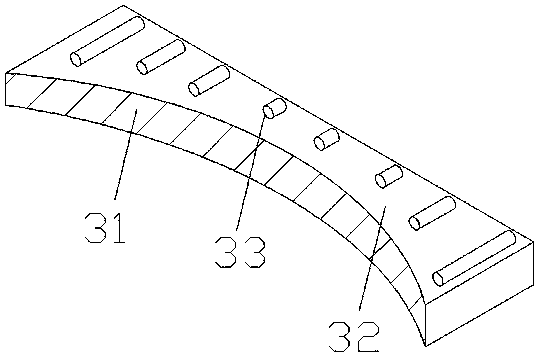

[0033] refer to figure 1 --7, a glass transfer device, a round glass corner intelligent polishing device, including two symmetrically arranged first workbench 1 and second workbench 2, two said first workbench 1 and A grinding device 4 is provided in the middle of the second workbench 2, wherein the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com