A Precise Positioning Method for Electrolytic Forming of Thin-walled Shells

A precise positioning, thin-walled shell technology, applied in electric machining equipment, electrochemical machining equipment, accessories, etc., can solve the problem of positioning error sensitivity, achieve high-precision positioning, improve positioning accuracy and reliability, reduce The effect of positioning adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

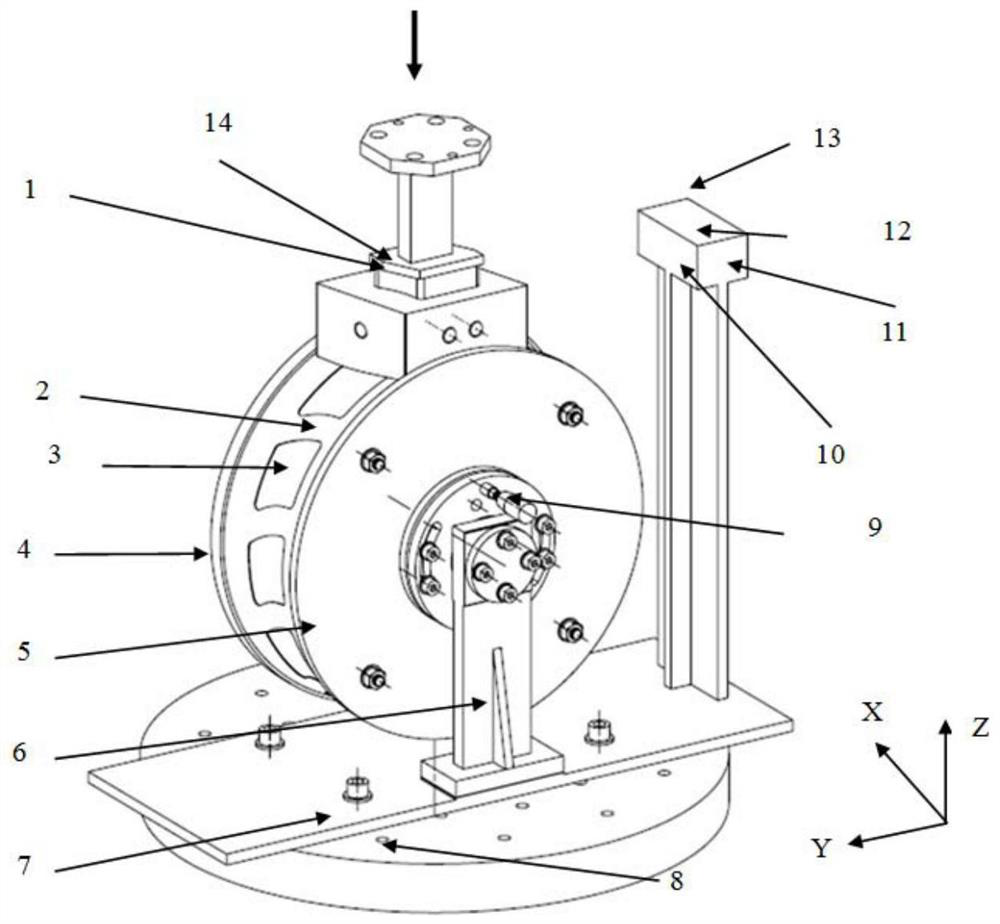

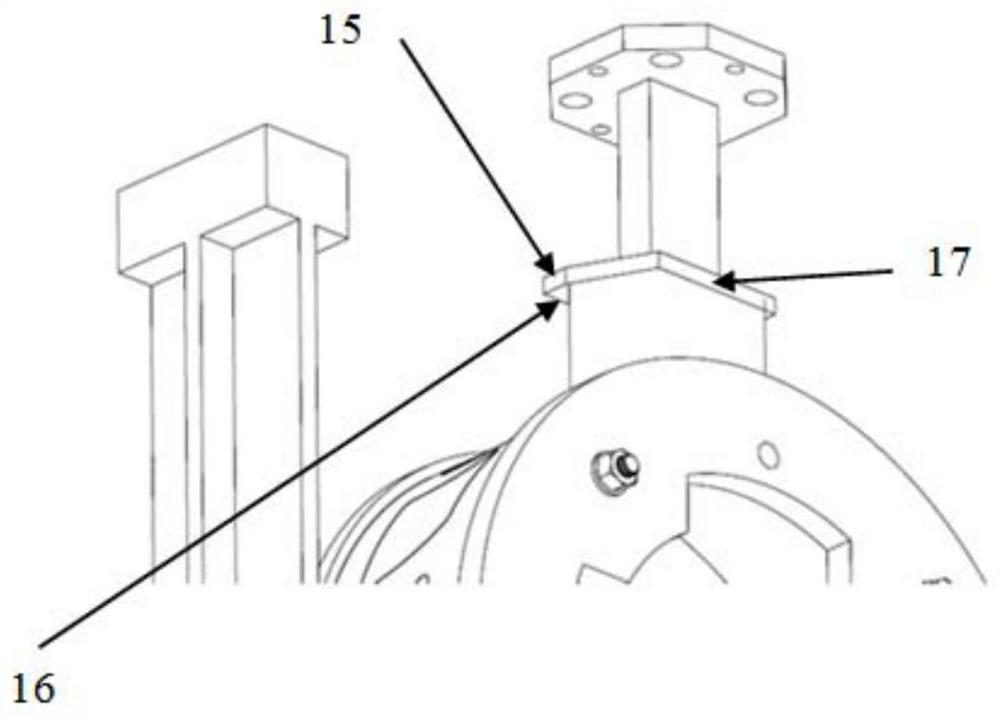

[0044] Example 1: Before electrolytic machining, the U18 reference plane 15 of the forming electrode 1 is brought into contact with the XZ reference plane 10 to obtain the Y coordinate value C of the machine tool 2 is 305.32; make the V19 reference plane 16 of the forming electrode 1 contact the XY reference plane 12, and obtain the Z coordinate value C of the machine tool 3 is 311.05; the W20 reference plane 17 of the forming electrode 1 is in contact with the YZ reference plane 11 to obtain the X coordinate value C of the machine tool 1 for 258.61. Then through the conversion formula X=C 1 -B 1 -A 1 ;y=C 2 -B 2 -A 2 ;z=C 3 -(B 3 / 2-T), that is, X=C 1 -B 1 -A 1 =258.61-20-100=138.61; y=C 2 -B 2 -A 2 =305.32-30-200=75.32; z=C 3 -(B 3 / 2-T)=311.05-(40-2-0.2)=291.25 The converted machine tool coordinates (138.61, 75.32, 291.25) are the initial machining coordinates of electrolytic machining.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com