Multi-dimensional plastic forming method and device for cold-state metal profile

A metal profile, plastic forming technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of low production efficiency, poor forming quality, inability to meet multi-dimensional requirements, etc., and achieve high forming efficiency and good forming effect. , the effect of enriching the spatial geometry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

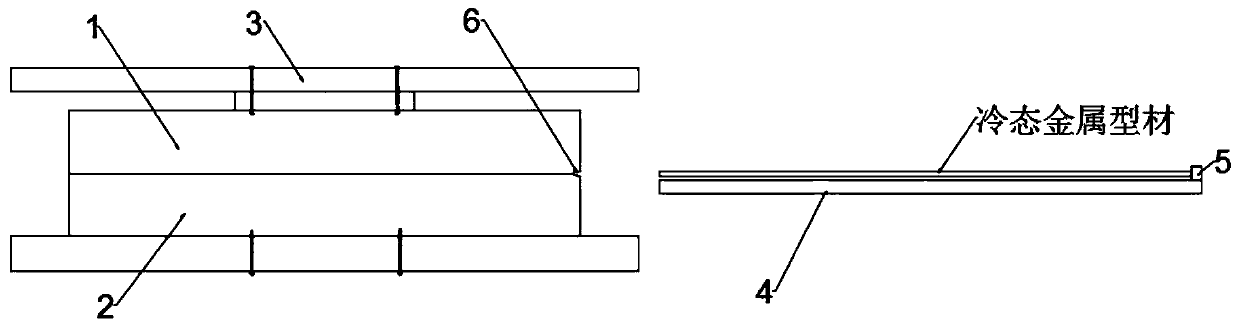

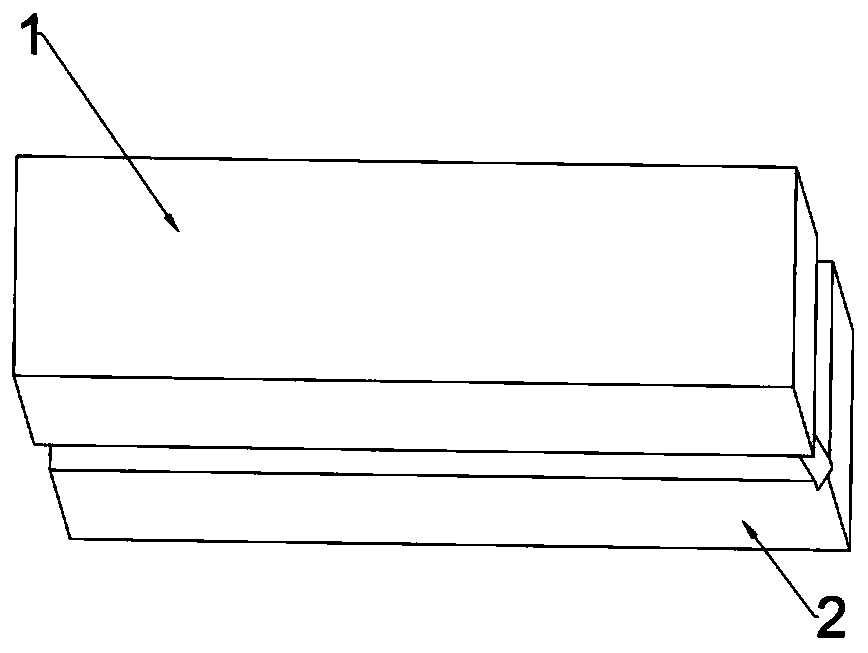

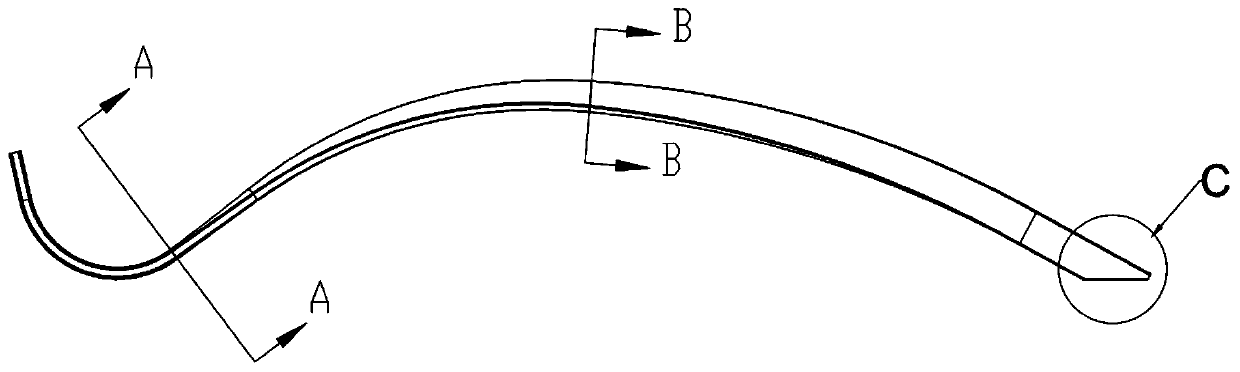

[0027] The method and device for multi-dimensional plastic forming of cold metal profiles of the present invention will be described in further detail below with reference to the accompanying drawings.

[0028] Attached Figure 1-9 , A method and device for multi-dimensional plastic forming of cold metal profiles:

[0029] A multi-dimensional plastic forming method for cold metal profiles, characterized in that the forming method steps are as follows:

[0030] 1. Multi-dimensional upper cavity and multi-dimensional lower cavity are closed to form a cavity;

[0031] 2. The sliding material guide rail is connected to the inlet of the cavity;

[0032] 3. The sliding material guide rail restricts the cold metal profile up and down, so that the cold metal profile moves in a straight direction;

[0033] 4. The pusher head pushes the cold metal profile toward the cavity;

[0034] 5. The cold metal profile flows and forms in the cavity;

[0035] 6. The feeding is completed;

[0036] 7. Open the mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com