Intelligent light supplementing device for seedling raising

An intelligent, supplementary light technology, applied in the field of agricultural seedlings, can solve the problems of uneven light, inconsistent crop growth speed, increased management costs, etc., and achieve the effect of flexible control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] An intelligent supplementary light device for seedling cultivation in this embodiment includes a sunlight shading module, a control module, an artificial light source module, and a data acquisition module.

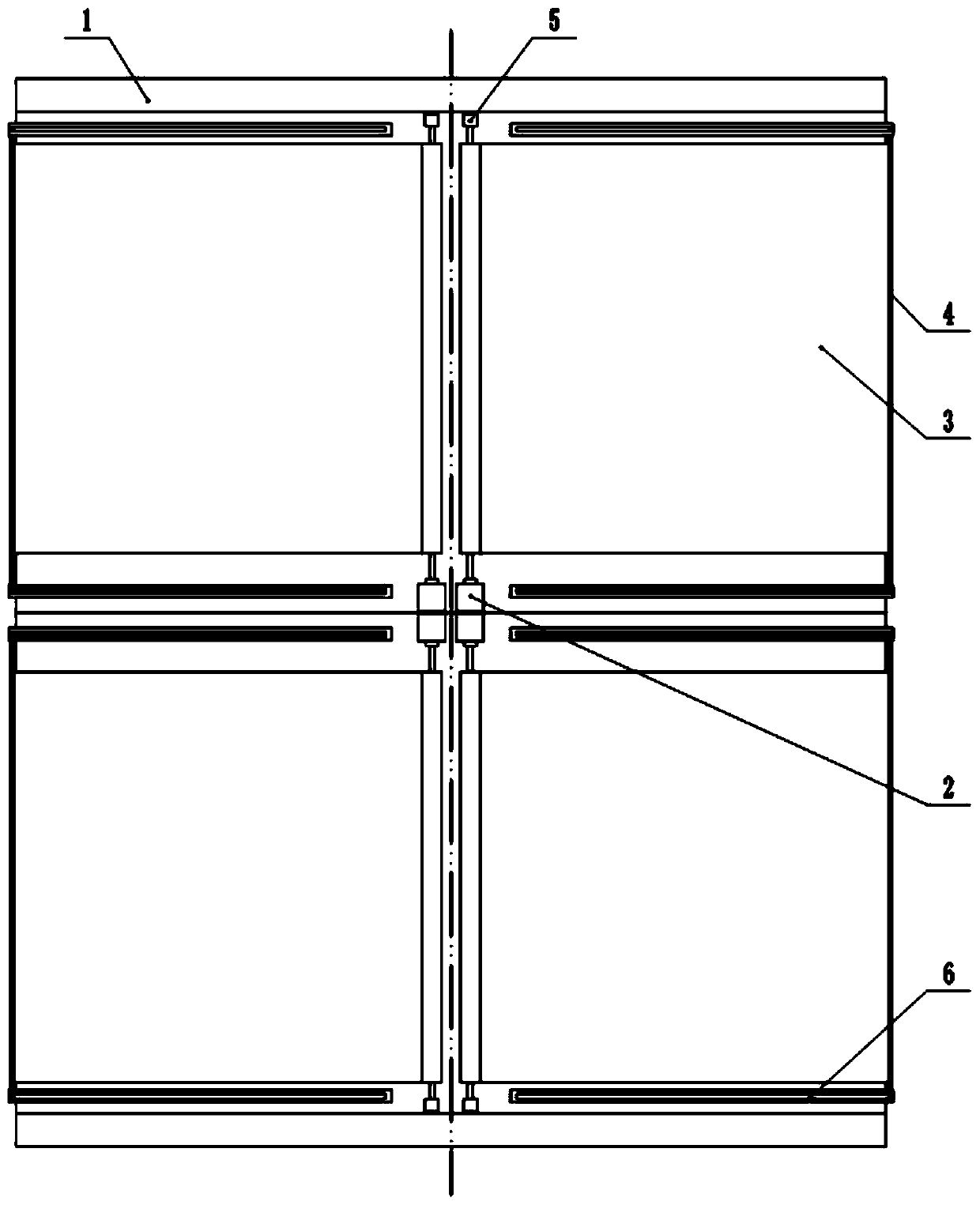

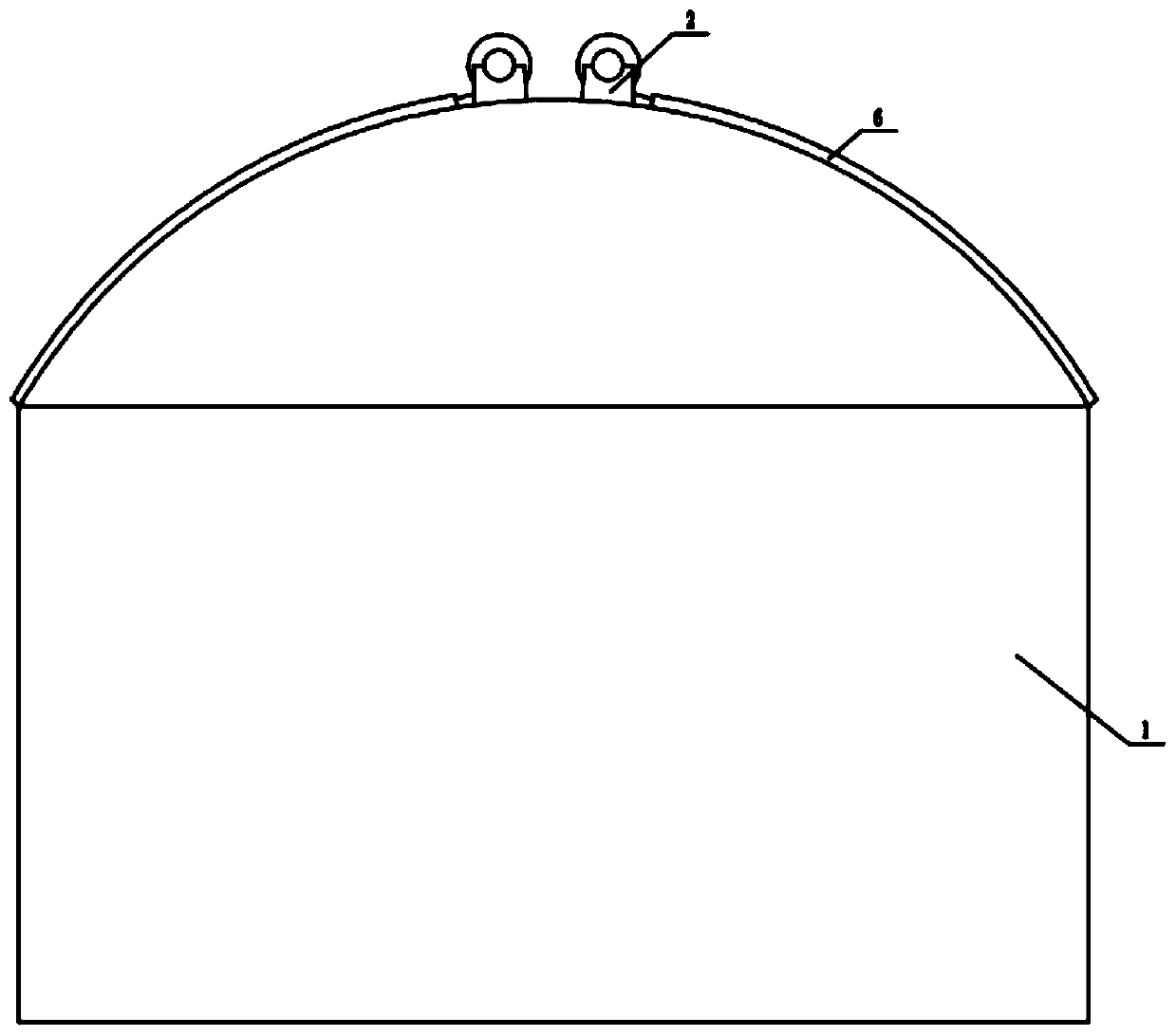

[0040] Such as figure 1 and figure 2 As shown, in this embodiment, the top of the greenhouse 1 is arc-shaped, and the axis of the top of the greenhouse 1 is used as the dividing line to divide the top of the greenhouse 1 into two symmetrical parts on the left and right, and each part is divided into several areas respectively. The division of the top area can be carried out according to the actual situation. For the convenience of management, it is sufficient to ensure that the left and right areas are symmetrical about the dividing line. The crops planted in the greenhouse 1 are divided according to the orthographic projection of the top area of the greenhouse 1. In other words, the division of the crop area and the division of the top area of the greenhouse ...

Embodiment 2

[0056] The difference between this embodiment and Embodiment 1 is that this embodiment also includes an image acquisition module, and the image acquisition module includes several cameras, and the cameras are used to collect images of crops every preset time. The preset time is 12-24 hours. 12 hours were used in this example. Each area corresponds to at least one camera, and the camera is used to collect images of crops in the corresponding area. When setting up the camera, it should be ensured that the leaves of the crops are clearly visible in the images captured by the camera.

[0057] The storage unit pre-stores crop growth cycle and light intensity demand data, crop leaf area and growth cycle data.

[0058] The processing unit is used to acquire the light intensity data of each area from the illumination sensor, and the image of the crops in each area from the camera; the processing unit calculates the current growth cycle of the crops in each area based on the images o...

Embodiment 3

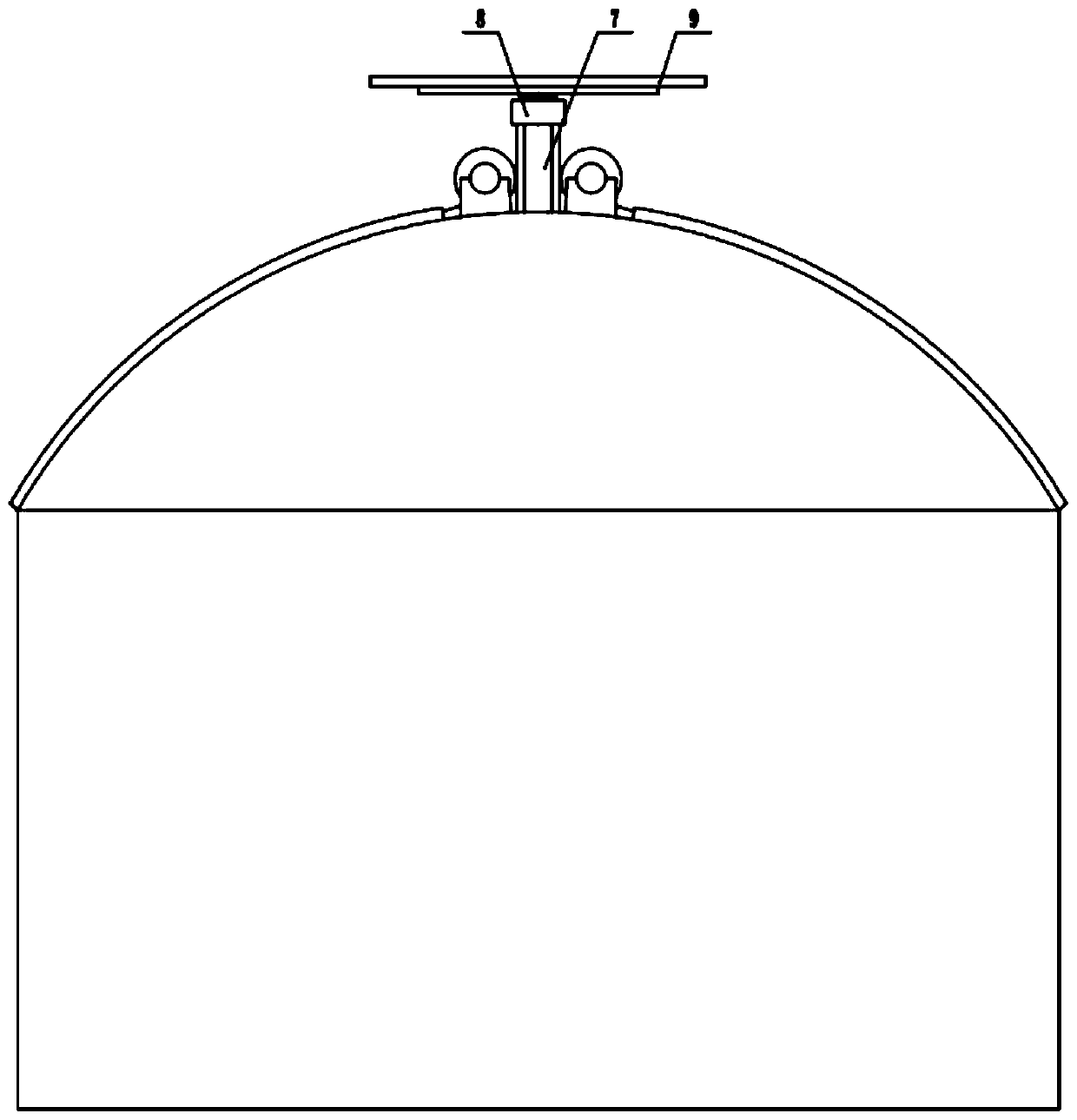

[0063] The difference between this embodiment and Embodiment 1 is that, if image 3 and Figure 4 As shown, it also includes a solar module and a ventilation module; the solar module includes a frame 7 , a rotating mechanism 8 and a solar panel 9 .

[0064] The lower end of the frame 7 is connected with the top of the greenhouse 1 by bolts; specifically, the frame 7 is located in the middle of the two shutter machines 2 at the top of the greenhouse 1; the upper end of the frame 7 is connected with the lower end of the rotating mechanism 8 by bolts; Solar panel 9-bolt connection. In this embodiment, the rotating mechanism 8 includes a servo motor and a harmonic reducer, the output shaft of the servo motor is connected to the input shaft of the harmonic reducer by bolts, and the output shaft of the harmonic reducer is connected to the solar panel 9 by bolts; in other In the embodiment, other rotating mechanisms 8 may also be used to realize the rotating function of the solar b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com