Lithium supplement paste for lithium secondary battery and preparation method of lithium secondary battery

A lithium secondary battery and lithium replenishment technology, which is applied in the manufacture of secondary batteries, battery electrodes, electrolyte batteries, etc., can solve the problems affecting the increase of energy density of lithium ion batteries, the reduction of active material ratio, and the lack of activity, so as to reduce irreversible Capacity loss, reduced loss, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

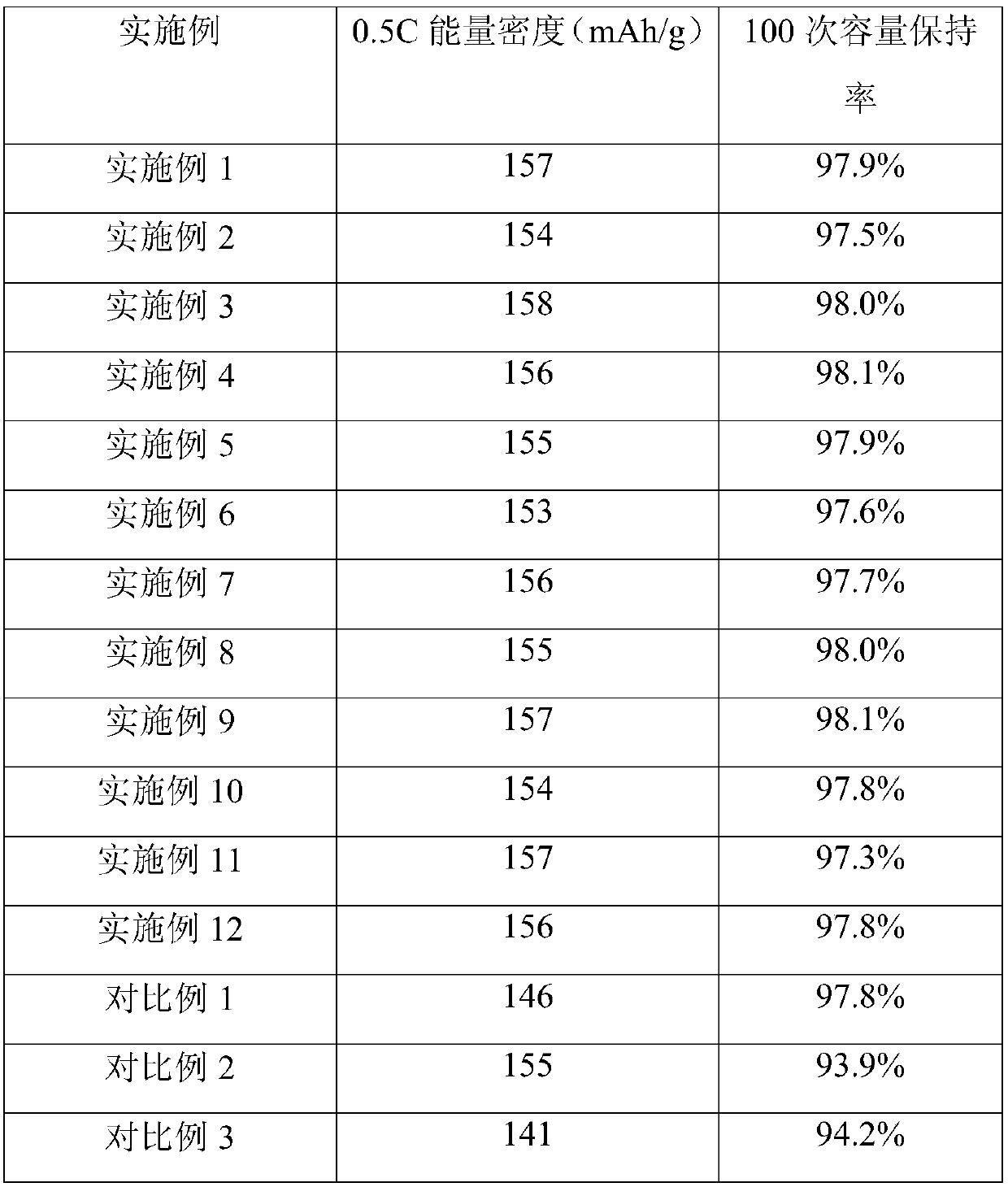

Embodiment 1

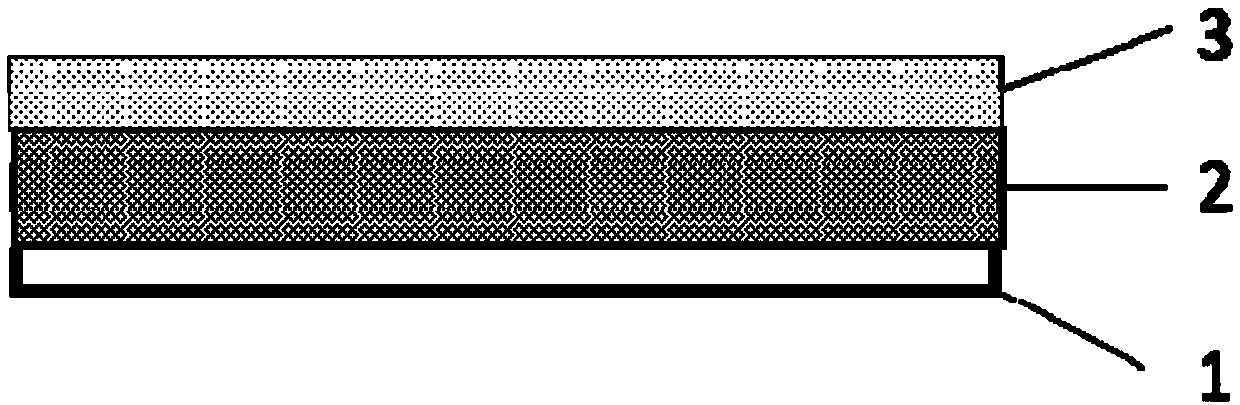

[0051] (1) Disperse nickel-cobalt lithium manganate (NCM523), conductive agent Super P (conductive carbon black, SP) and polyvinylidene fluoride (binder PVDF) in N-methylpyrrolidone at a mass ratio of 93:4:3 (NMP), forming a positive electrode active material slurry. The positive electrode active material slurry was coated on the surface of aluminum foil (conductive substrate), then dried in an oven at 100°C for 3 hours, and rolled to obtain a positive electrode sheet coated with a positive electrode active material layer (thickness: 50 μm).

[0052] (2) Disperse Li3N, conductive carbon fiber (VGCF), and binder polymethyl methacrylate (PMMA) in the organic solvent N-methylpyrrolidone (NMP) at a mass ratio of 49:49:2 to form a lithium supplement slurry. The lithium-replenishing slurry was coated on the surface of the positive electrode sheet obtained in step (1), and then dried in an oven at 100° C. for 3 hours to finally form a lithium-replenishing positive electrode sheet wi...

Embodiment 2

[0056] (1) Disperse nickel-cobalt lithium manganate (NCM523), conductive agent Super P (conductive carbon black, SP) and polyvinylidene fluoride (binder PVDF) in N-methylpyrrolidone at a mass ratio of 93:4:3 (NMP), forming a positive electrode active material slurry. The positive electrode active material slurry was coated on the surface of aluminum foil (conductive substrate), then dried in an oven at 100° C. for 3 h, and rolled to obtain a pole piece coated with a positive electrode active material layer (thickness 450 μm).

[0057] (2) will Li 3 N. The conductive agent (VGCF) and the binder polymethyl methacrylate (PMMA) are dispersed in the organic solvent N-methylpyrrolidone (NMP) at a mass ratio of 90:5:5 to form a lithium-supplementing slurry. The lithium-replenishing slurry was coated on the surface of the positive electrode sheet obtained in step (1), and then dried in an oven at 100° C. for 3 hours to finally form a lithium-replenishing positive electrode sheet with...

Embodiment 3

[0061] (1) Disperse nickel-cobalt lithium manganate (NCM523), conductive agent Super P (conductive carbon black, SP) and polyvinylidene fluoride (binder PVDF) in N-methylpyrrolidone at a mass ratio of 93:4:3 (NMP), forming a positive electrode active material slurry. The positive electrode active material slurry was coated on the surface of aluminum foil (conductive substrate), then dried in an oven at 100° C. for 3 h, and rolled to form a pole sheet coated with a positive electrode active material layer (thickness 200 μm).

[0062] (2) will Li 3 N. The conductive agent (VGCF) and the binder polymethyl methacrylate (PMMA) are dispersed in the organic solvent N-methylpyrrolidone (NMP) at a mass ratio of 49:46:5 to form a lithium-supplementing slurry. The lithium-replenishing slurry was coated on the surface of the positive electrode sheet obtained in step (1), and then dried in an oven at 100° C. for 3 hours to finally form a lithium-replenishing positive electrode sheet with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com