A kind of gas explosion suppressant and preparation method thereof

An anti-explosion agent and gas technology, which is applied in mining equipment, earthwork drilling, dust prevention, etc., can solve the problems of high energy consumption and single-function effect of anti-explosion materials, so as to reduce the concentration of methane and attenuate explosion shock waves and flame waves , the effect of suppressing the explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

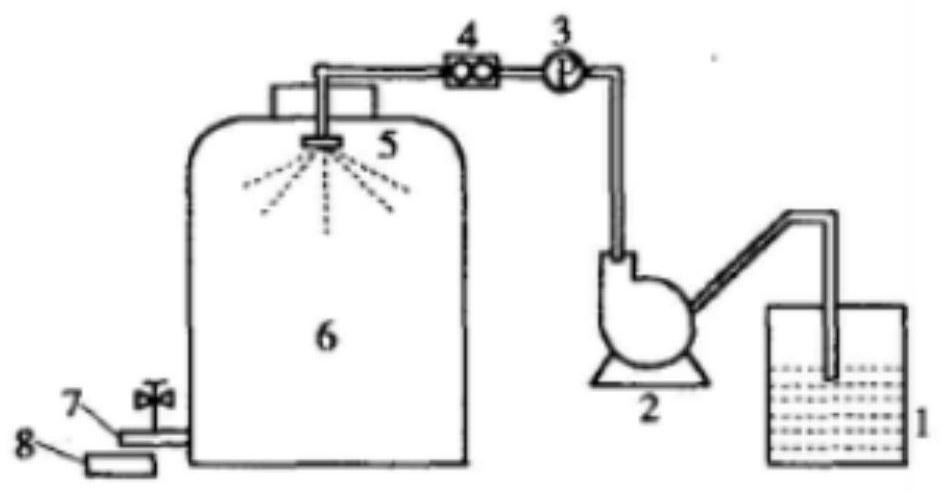

Image

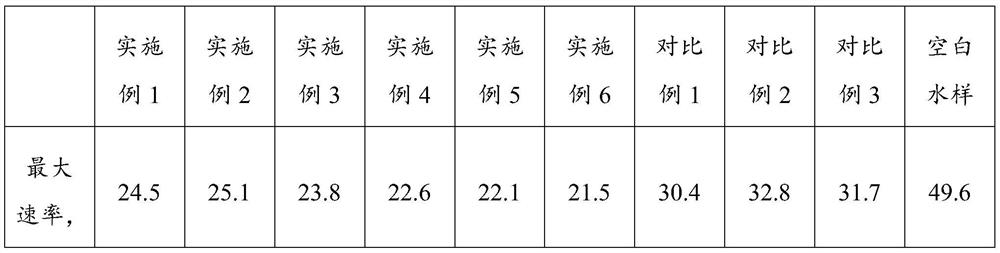

Examples

Embodiment 1

[0044] This embodiment provides a gas explosion suppressant, comprising the following components by weight,

[0045] Pseudo-boehmite 70g;

[0046] Water glass (in terms of the mass of silicon dioxide, the concentration of said water glass is 30%) 35g;

[0047] Aluminum sulfate aqueous solution (10%) 150g;

[0048]Sodium hydroxide aqueous solution (80%) 100g;

[0049] Metal ruthenium salt (ruthenium trichloride) 10g;

[0050] 20 g of nonionic surfactants, including 10 g of nonylphenol polyoxyethylene ether TX-10 and 10 g of coconut oil diethanolamide.

[0051] The preparation method of described antiknock agent is specifically:

[0052] Add 20g of pseudo-boehmite into aqueous sodium hydroxide solution, stir and mix well at 40°C to obtain mixed solution A;

[0053] Mix the obtained mixed solution A with water glass and stir at 30°C for 3 hours to obtain the mixed solution B;

[0054] Mix the remaining pseudo-boehmite with mixed solution B, aluminum sulfate aqueous solution...

Embodiment 2

[0057] This embodiment provides a gas explosion suppressant, comprising the following components by weight,

[0058] Pseudoboehmite 30g;

[0059] Water glass (in terms of the mass of silicon dioxide, the concentration of said water glass is 20%) 55g;

[0060] Aluminum sulfate aqueous solution (20%) 130g;

[0061] Sodium hydroxide aqueous solution (60%) 120g;

[0062] Metal ruthenium salt (ruthenium trichloride) 5g;

[0063] Nonionic surfactant 30g, wherein, nonylphenol polyoxyethylene ether OP-10 8g, coconut oil diethanolamide 12g, Tween-80 8g.

[0064] The preparation method of described antiknock agent is specifically:

[0065] Add 10g of pseudo-boehmite into aqueous sodium hydroxide solution, stir and mix well at 30°C to obtain mixed solution A;

[0066] Mix the obtained mixed solution A with water glass and stir at 45°C for 2 hours to obtain the mixed solution B;

[0067] Mix the remaining pseudo-boehmite with mixed solution B, aluminum sulfate aqueous solution, and ...

Embodiment 3

[0070] This embodiment provides a gas explosion suppressant, comprising the following components by weight,

[0071] Pseudoboehmite 50g;

[0072] Water glass (in terms of mass of silicon dioxide, the concentration of said water glass is 25%) 45g;

[0073] Aluminum sulfate aqueous solution (15%) 140g;

[0074] Sodium hydroxide aqueous solution (70%) 140g;

[0075] Metal ruthenium salt (ruthenium trichloride) 8g;

[0076] Nonionic surfactant 25g, wherein, coconut oil diethanolamide 12g, Tween-80 6g, Span-80 7g.

[0077] The preparation method of described antiknock agent is specifically:

[0078] Add 15g of pseudo-boehmite into aqueous sodium hydroxide solution, stir and mix well at 35°C to obtain mixed solution A;

[0079] Mix the obtained mixed solution A with water glass and stir at 40°C for 2.5 hours to obtain the mixed solution B;

[0080] Mix the remaining pseudo-boehmite with mixed solution B, aluminum sulfate aqueous solution, and metal ruthenium salt, stir and mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com