A composite perforating gun

A compound perforating and perforating gun technology, which is applied in wellbore/well components, production fluid, earthwork drilling and production, etc. It can solve the problems of low production efficiency, easy leakage, low sealing and pressure bearing performance of perforating guns in blind holes, etc. To solve the problem, to achieve the effect of convenient operation, increase of seepage area, and improvement of perforation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

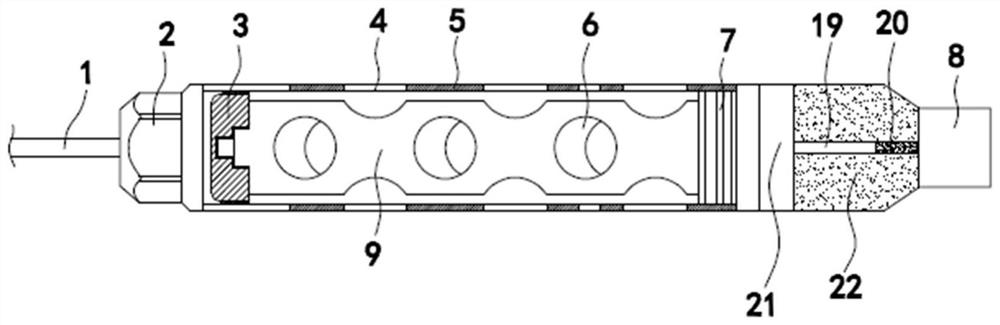

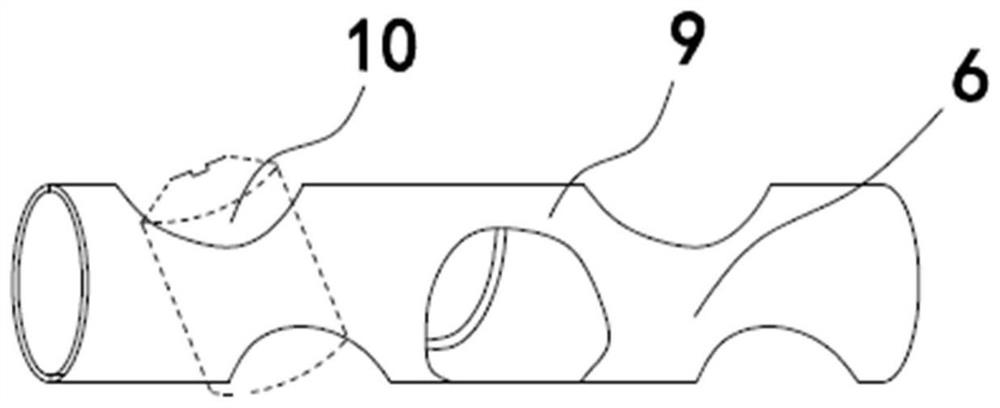

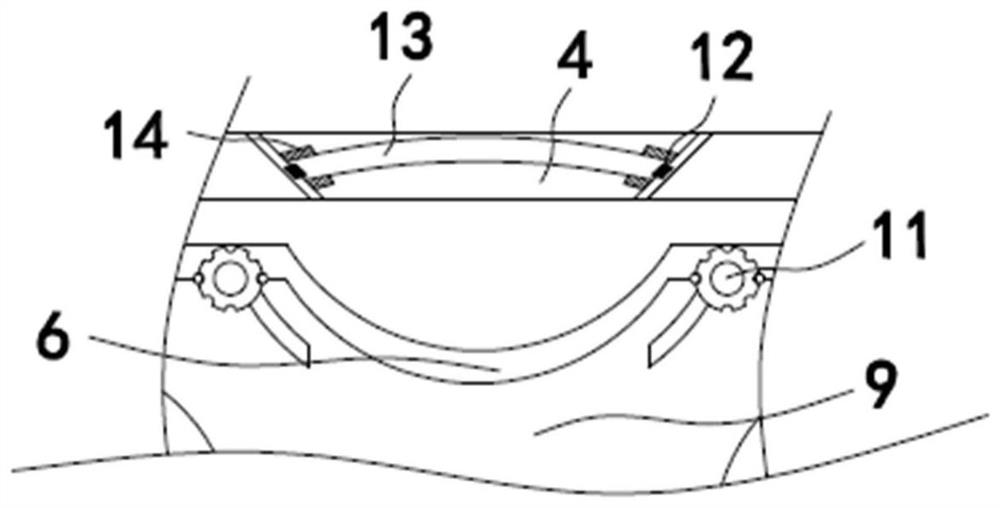

[0024] Such as Figure 1-7 As shown, a new composite perforating gun includes a gun head 1, a perforating gun body 5, and a gun tail 8. A number of blind holes 4 are opened on the surface of the perforating gun body 5, and a bullet rack 9 is arranged inside the perforating gun body 5. , the loading hole 6 provided on the surface of the bullet holder 9 corresponds to the blind hole 4, the blind hole 4 is in the shape of an inverted cone, and the inclined surface of the blind hole 4 is fixedly connected with a symmetrical block 14, between the symmetrical blocks 14 A baffle 13 is plugged in, and an O-ring 12 is provided at the contact position between the baffle 13 and the inclined surface of the blind hole 4 . The blind hole on the surface of the perforating gun corresponds to the loading hole. The blind hole has good sealing and pressure relief through the above design. At the same time, there is a baffle plate thinner than the gun body in the blind hole. This area is relative...

Embodiment 2

[0032] Such as Figure 1-7 As shown, in the actual use of a new compound perforating gun, the perforating gun is assembled, and the perforating gun is transported to the area to be detonated through the cable 1, and the detonator is detonated, and the perforating charge 10 will crush the blind The baffle plate 13 in the hole 4 passes through the blind hole 4 to realize perforation. After detonating the perforating charge 10, the detonation is converted into combustion through the detonation joint 21, and the flame generated by the detonation joint 21 ignites the central hole of the fracturing powder 22 The high-temperature ignition powder 20 inside, the high temperature generated by the ignition powder 20 causes the fracturing powder to burn 22, the amount of the powder is not limited, the gas produced by the powder will be directly sprayed into the formation, so that the formation around the wellbore will generate multiple lines that are not affected by the formation minimum ...

Embodiment 3

[0034] Select the perforating gun of the present invention (test group) and the common same type perforating gun (control group) on the market, the outer diameter of the two groups of perforating guns, the bullet length of the perforating bullet, the outer cone angle of the bullet, and the charge amount Parameters such as perforation density and perforation density are the same. The two groups of perforating guns are transported to the location where detonation is required underground. The data of blasting height, penetration depth, and burr height in blind holes, the experimental results are provided by the attached Figure 5 , 6 , as shown in Table 7:

[0035] According to attached Figure 5 , 6 From the data shown in , 7, it can be clearly seen that the experimental results of the perforating gun of the present invention in blasting height, penetration depth, and burr height in blind holes are obviously better than common perforating guns of the same type on the market. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com