Method for preparing novel high-performance cigarette paper by using base paper for cigarettes, and improved equipment of method

A high-performance technology for cigarette paper, applied in the direction of paper, papermaking, paper coating, etc., can solve the problems of inconvenient adjustment of drying strength and method, achieve improved drying effect, reasonable and effective preparation process, and good drying effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

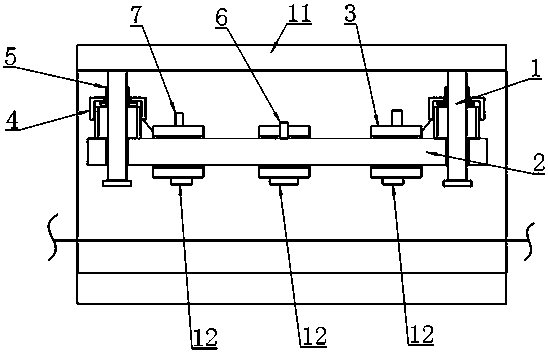

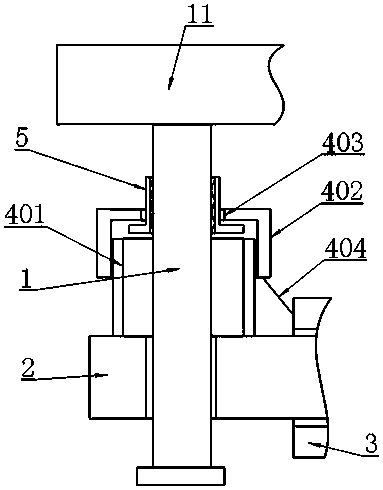

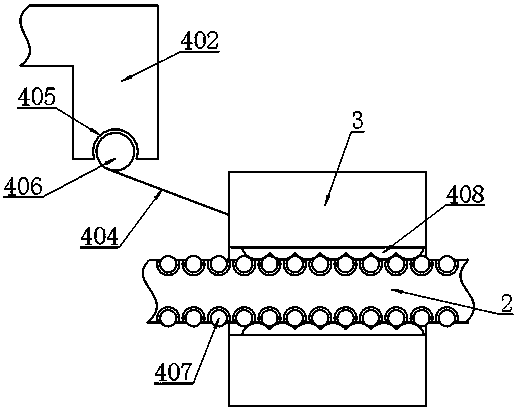

[0032] Example: as attached figure 1 , 2 , 3 and attached Figure 4 Shown, a kind of method utilizing cigarette base paper to prepare high-performance novel cigarette paper is characterized in that comprising the following steps successively:

[0033] S1, preparation of additive base liquid, the ingredients include water, sodium alginate and amino acid;

[0034] S2. Uniformly adding the flavor system formed by the mutual dissolution of several oil-soluble flavors into the additive base liquid to obtain the final flavor additive;

[0035] S3. Coating the essence additive on the base paper for cigarettes and drying to obtain the final cigarette paper.

[0036] In step S1, the amino acid includes a mixture of any two of serine, alanine, and aspartic acid; in step S2, the oil-soluble essence includes at least two of peppermint oil, rose oil, mugwort oil, and chamomile oil mixture. In step S2, after the addition of the essence system is completed, it is left to stand for 4-5 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com