A kind of zinc leaching slag volatilization kiln treatment method

A technology of zinc leaching slag and treatment method, applied in the field of metallurgy, can solve the problems of insufficient and effective utilization of red mud, occupation of land, environmental pollution, etc., and achieve the effects of improving service life, reducing the generation of zinc sulfide, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

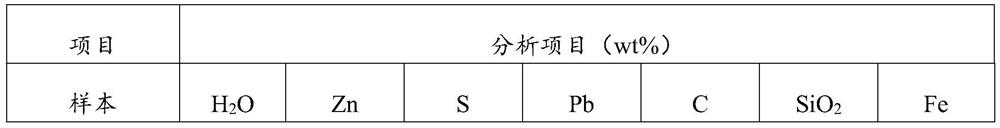

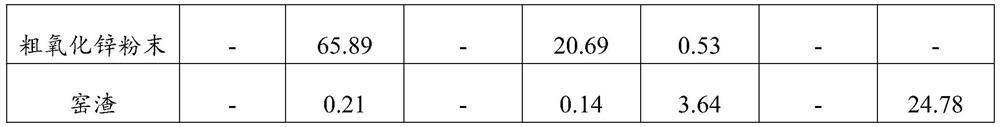

Image

Examples

Embodiment 1

[0028] A method for treating zinc leaching slag in a volatilization kiln, comprising the steps of:

[0029] (1) Take zinc leaching slag, Zn18%, Fe22%, SiO 2 9%, Pb3.5%, S4%, Ca1%, Mg2.5%, water content 20%, and the rest are impurities; the above-mentioned zinc leaching slag is dried to a water content of 8%, and ground to obtain a particle size of 100 μm Zinc leaching slag scrap;

[0030] (2) pulverizing the anthracite into coal powder with a particle diameter of 2 mm;

[0031] (3) Take the following mass fraction of alumina waste red mud, Fe 2 o 3 : 16%, SiO 2 : 15%, Al 2 o 3 : 20%, Na 2 O: 8%, and the rest are impurities; the above-mentioned alumina waste red mud is dried to a moisture content of 10%, and ground to obtain red mud powder with a particle size of 1 mm;

[0032] (4) The above-mentioned zinc leaching slag fragments, coal powder, red mud powder, and limestone powder with a particle size of 1mm are mixed evenly in a mass ratio of 100:30:35:1, and water is a...

Embodiment 2

[0035] A method for treating zinc leaching slag in a volatilization kiln, comprising the steps of:

[0036] (1) Take the following zinc leaching slag in mass fraction, Zn17%, Fe22.5%, SiO 2 9.5%, Pb3%, S4.2%, Ca2%, Mg1.8%, water content 18%, and the rest are impurities; the above-mentioned zinc leaching slag is dried to a water content of 7%, and ground to obtain a particle size of 125 μm Zinc leaching slag scrap;

[0037] (2) pulverizing the anthracite into coal powder with a particle size of 2.8mm;

[0038] (3) Take the following mass fraction of alumina waste red mud, Fe 2 o 3 : 18%, SiO 2 : 12%, Al 2 o 3 : 18%, Na 2 O: 7%, and the rest are impurities; the above-mentioned alumina waste red mud is dried to a moisture content of 9%, and ground to obtain red mud powder with a particle size of 1.2mm;

[0039] (4) The above-mentioned zinc leaching slag fragments, coal powder, red mud powder and limestone powder with a particle size of 1.5mm are mixed uniformly in a mass ...

Embodiment 3

[0042] A method for treating zinc leaching slag in a volatilization kiln, comprising the steps of:

[0043] (1) Take the following zinc leaching slag in mass fraction, Zn16.4%, Fe23%, SiO 2 10%, Pb3.6%, S4.5%, Ca2.4%, Mg1.2%, water content 19%, and the rest are impurities; the above-mentioned zinc leaching slag is dried to a water content of 6.8%, and ground to obtain Zinc leaching slag fragments with a particle size of 150 μm;

[0044] (2) pulverizing the anthracite into coal powder with a particle size of 3.5 mm;

[0045] (3) Take the following mass fraction of alumina waste red mud, Fe 2 o 3 : 20%, SiO 2 : 10%, Al 2 o 3 : 17%, Na 2 O: 6%, and the rest are impurities; the above-mentioned alumina waste red mud is dried to a moisture content of 8%, and ground to obtain red mud powder with a particle size of 1.5 mm;

[0046] (4) The above-mentioned zinc leaching slag fragments, coal powder, red mud powder and limestone powder with a particle size of 2mm are mixed evenly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com