Chemical industry fermentation device capable of performing uniform stirring

A uniform stirring and fermentation device technology, which is applied to mixers with rotating stirring devices, biochemical cleaning devices, bioreactors/fermenters for specific purposes, etc. It can solve the problems of inability to stir and mix, affect fermentation, uneven stirring, etc. problem, to achieve the effect of ingenious design of stirring structure, guarantee of fermentation effect and improvement of fermentation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

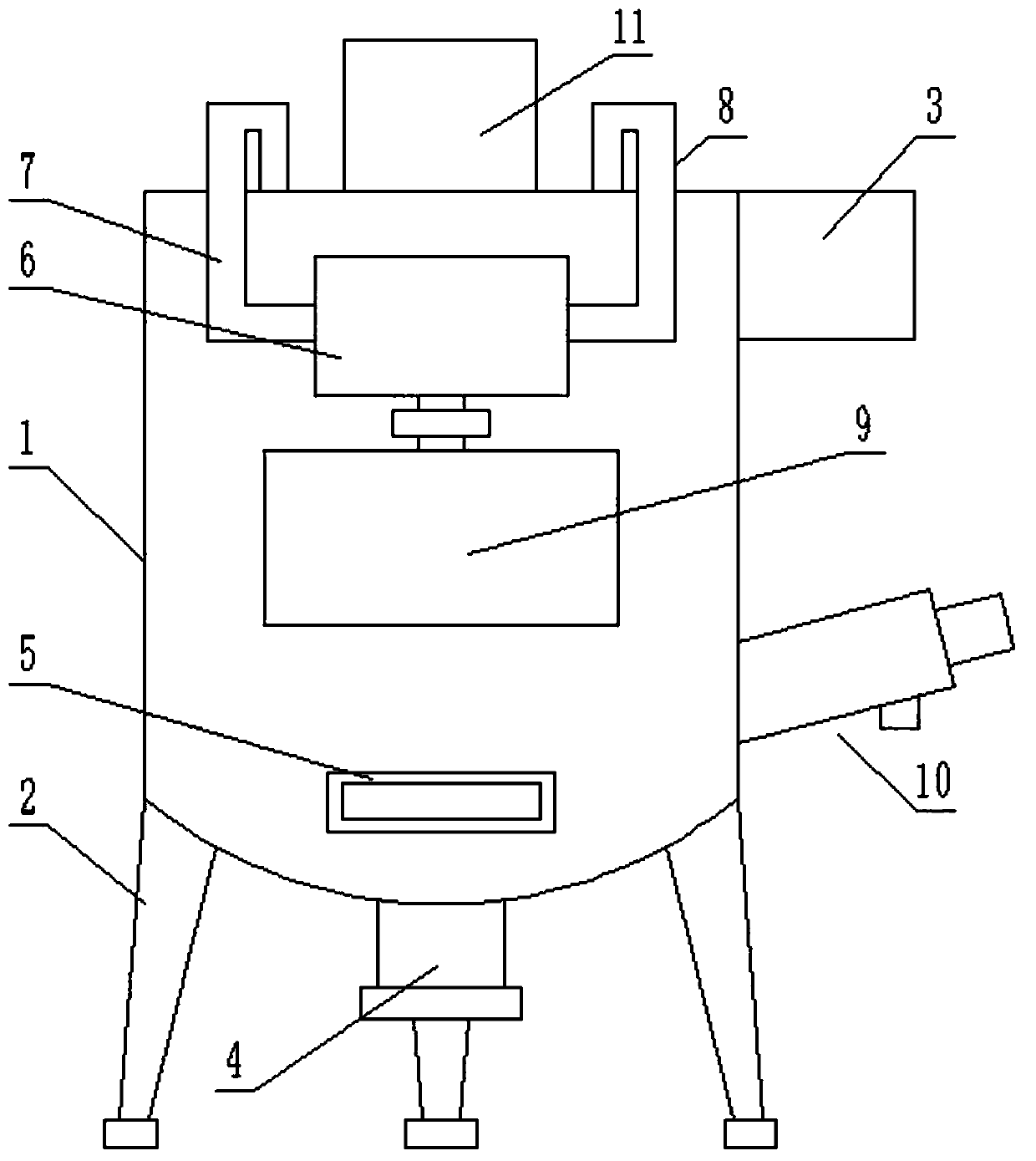

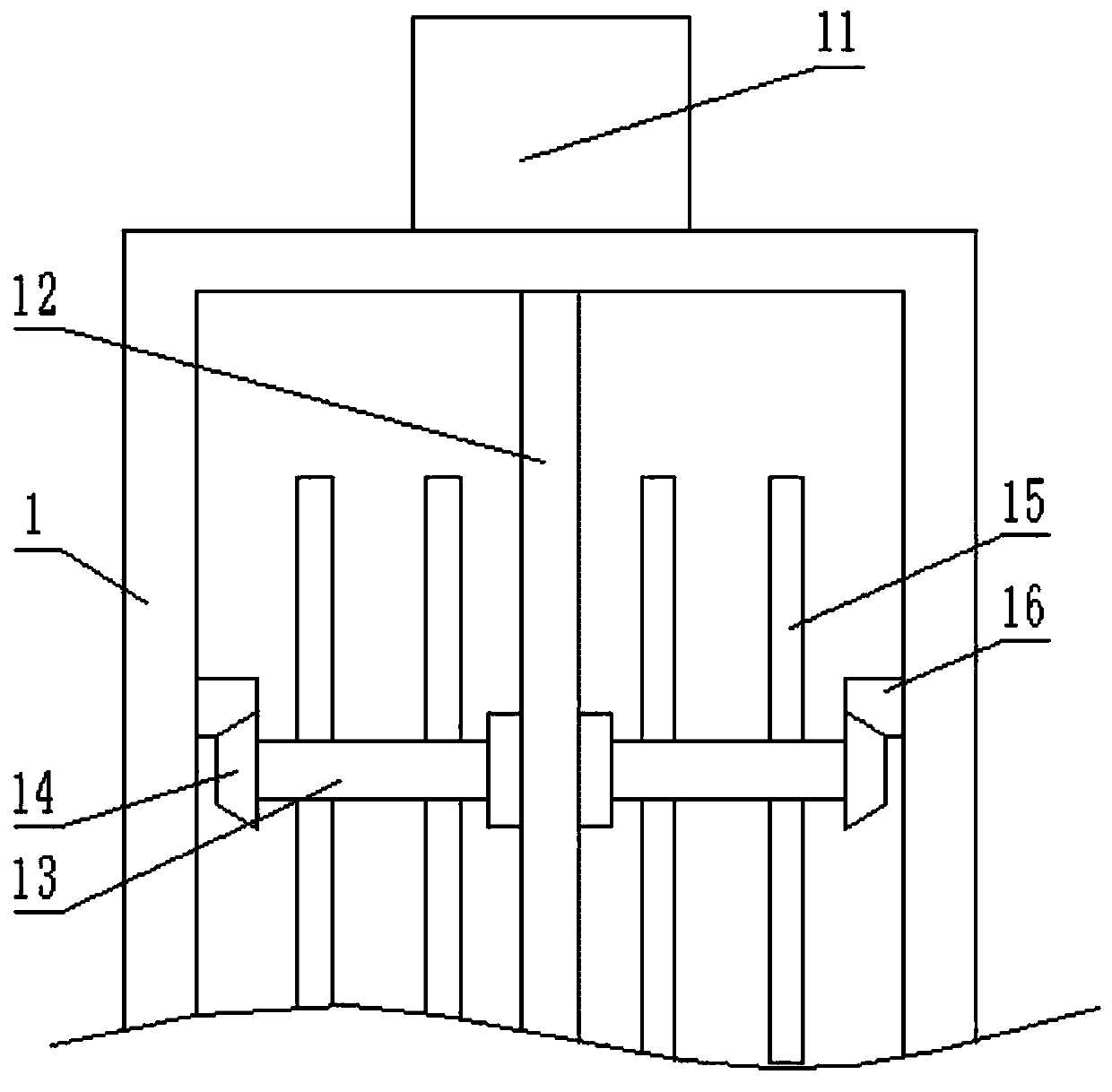

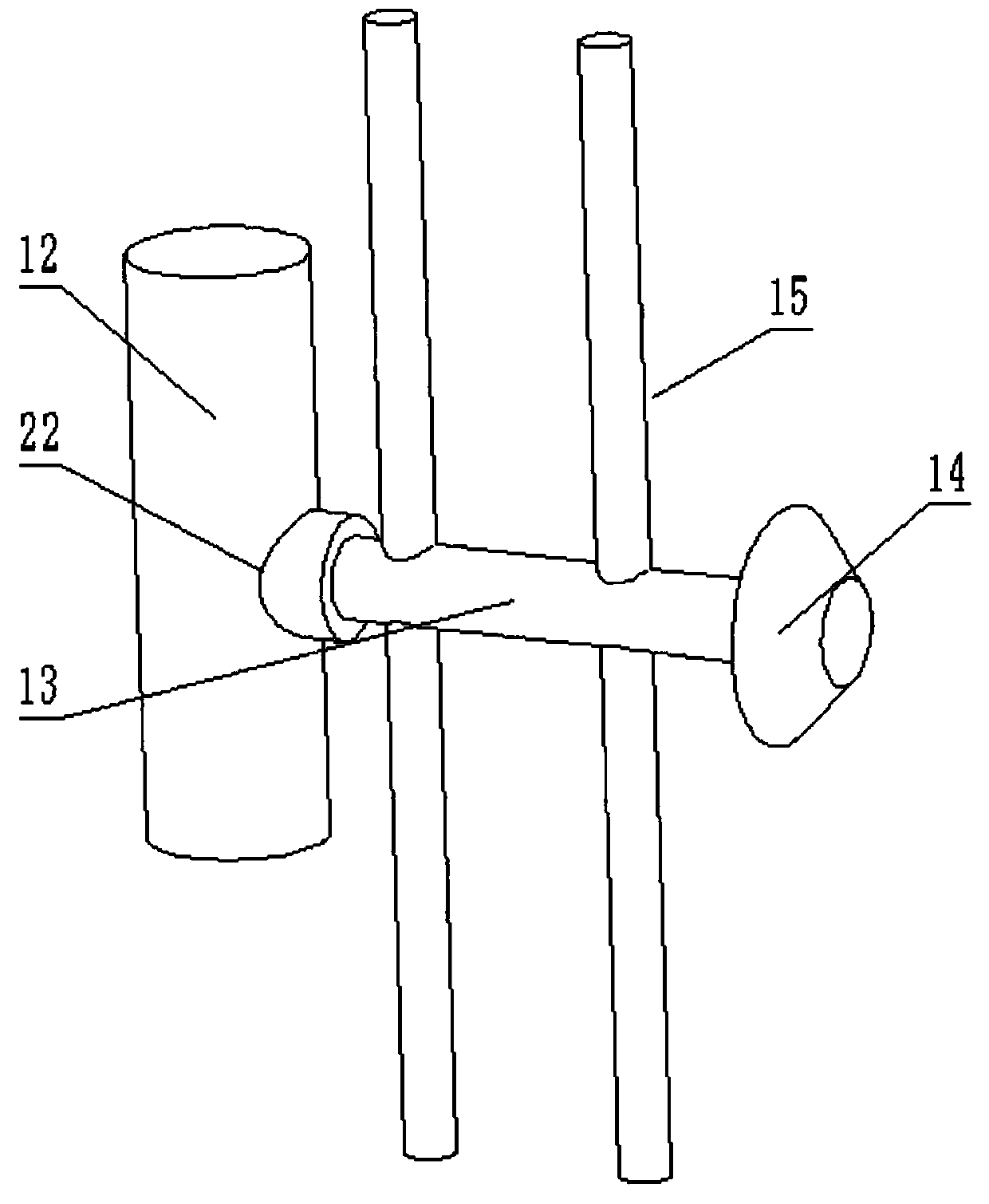

[0019] see Figure 1-3 , a uniformly stirred chemical fermentation device, comprising a tank body 1, a plurality of support legs 2 are provided at the bottom of the tank body 1, a feed box 3 is provided at the top of the side of the tank body 1, and a discharge port is provided at the bottom of the tank body 1 4. A drive motor 11 is provided in the center of the top of the tank body 1, and a stirring structure connected with the drive motor 11 is provided inside the tank body 1. Before fermentation, raw materials are put into the tank body 1 from the feed box 3 , and seal the feed box 3 and the discharge port 4, and then drive the stirring structure to rotate through the driving motor 11, and mix the various raw materials evenly under the stirring action through the stirring structure, thereby improving the fermentation efficiency and ensuring the fermentation effect; Specifically, the stirring structure includes a central axis rod 12, which is fixedly connected with the outpu...

Embodiment 2

[0023] refer to figure 1 , Figure 4 , on the basis of Example 1, the bottom side of the tank body 1 is also provided with a sampling tube 10, the sampling tube 10 is used to sample the raw materials during the fermentation process, to grasp the effect of fermentation in real time, the sampling tube 10 Including inclined pipe 18, which is inclined at an angle of 30° with the horizontal plane, a sampling motor 17 is arranged on the top of inclined pipe 18, a sampling port 20 is provided at the bottom of the upper end of inclined pipe 18, and an exhaust port 21 is provided at the top of the upper end of inclined pipe 18 , the inclined tube 18 is provided with the auger shaft 19 connected with the sampling motor 17 transmission, when sampling, the sampling port 20 and the exhaust port 21 are opened to keep the pressure balance in the sampling process in the inclined tube 18, driven by the sampling motor 17 The auger shaft 19 rotates so that the raw material in the tank body 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com