Production formula and preparation method of electronic cigarette emulsified essence

A technology for emulsified essence and production formula, applied in the directions of essential oil/spice, tobacco, fat production, etc., can solve the problems of insufficient stirring, large sensory gap, affecting the quality of essence, etc., to improve emulsifying ability, reduce impact, and improve flocculation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

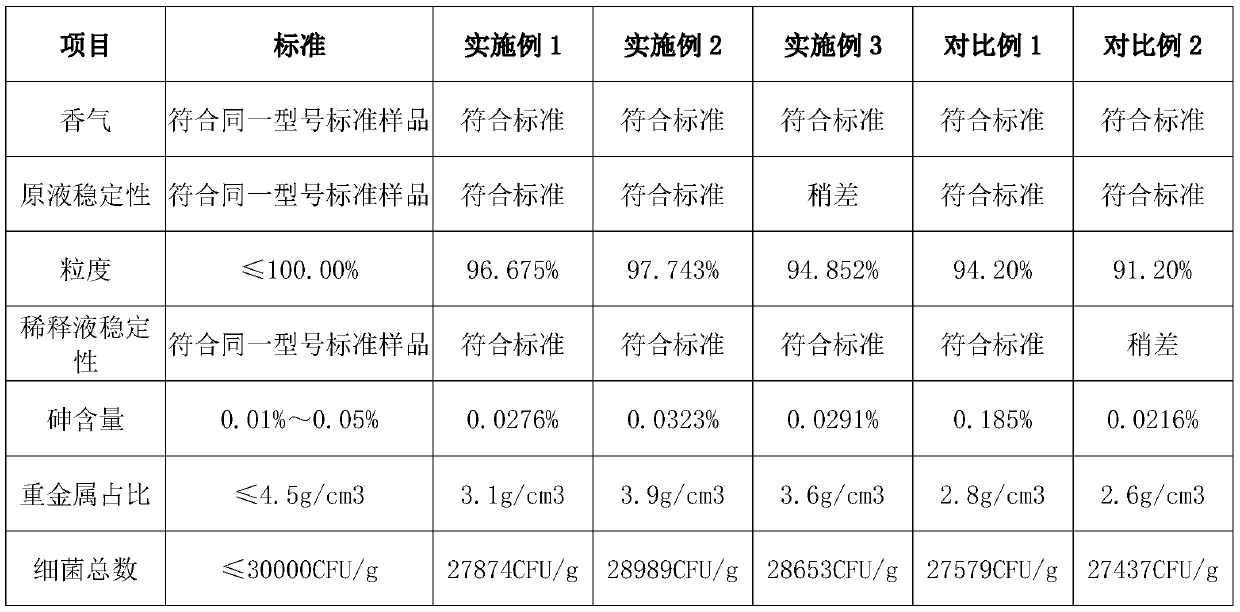

Examples

preparation example Construction

[0024] The invention provides a technical solution: a production formula and preparation method of emulsified flavor of electronic cigarette, which is composed of the following: food flavor, antioxidant, emulsifier, modified starch, thickener, preservative and deionized water; wherein The edible essence is the main ingredient, the antioxidant, emulsifier, and modified starch are auxiliary materials, and the thickener, deionized water and preservative are base materials;

[0025] The main material, auxiliary material and base material are composed according to the following parts by weight: 45-55 parts of edible essence, 5-8 parts of antioxidant, 10-15 parts of emulsifier, 2-5 parts of modified starch, and 3-6 parts of thickener , 1-3 parts of preservatives and 60-100 parts of deionized water.

[0026] The emulsifier is a mixed emulsion of sorbitan fatty acid ester and polyglycerin fatty acid ester in a mass ratio of 1:1.5.

[0027] The thickener is a kind of gum arabic or pec...

Embodiment 1

[0041] 45 parts of food flavor, 5 parts of antioxidant, 10 parts of emulsifier, 2 parts of modified starch, 3 parts of thickener, 1 part of preservative and 60 parts of deionized water.

Embodiment 2

[0043] 50 parts of edible essence, 6 parts of antioxidant, 12 parts of emulsifier, 3 parts of modified starch, 4 parts of thickener, 2 parts of preservative and 80 parts of deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com