A deflection ball conveying mechanism

A technology of conveying mechanism and deflection mechanism, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of limited scope of goods suitable for deflection wheels, restricted use scenarios, etc., and achieve reliable deflection direction, improve transmission force, Uniform force transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

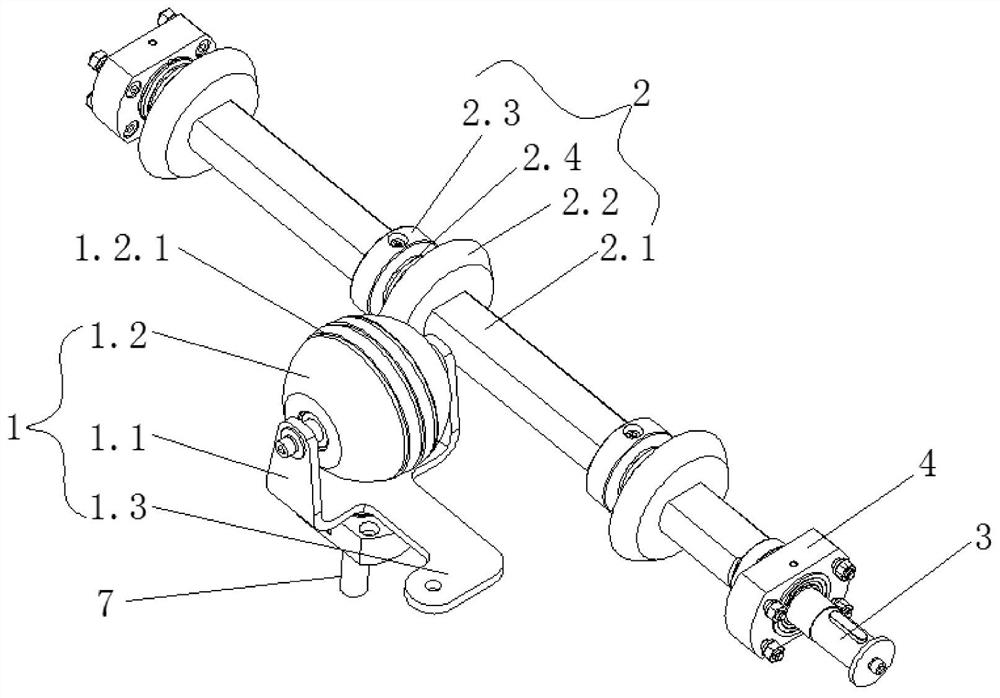

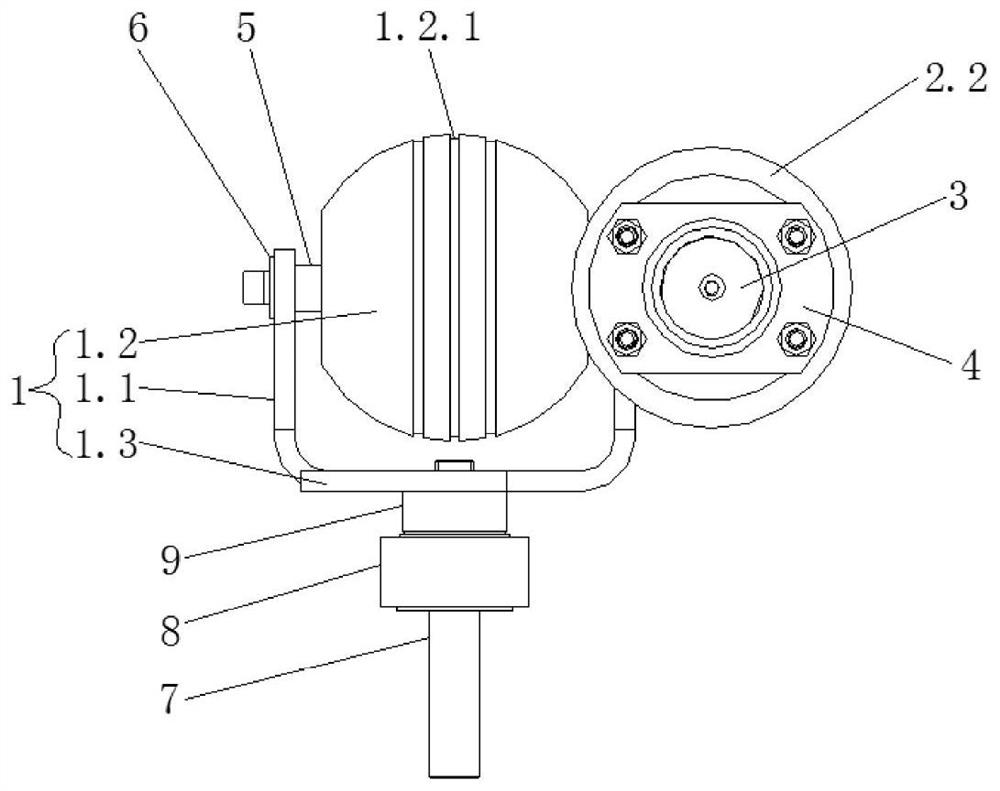

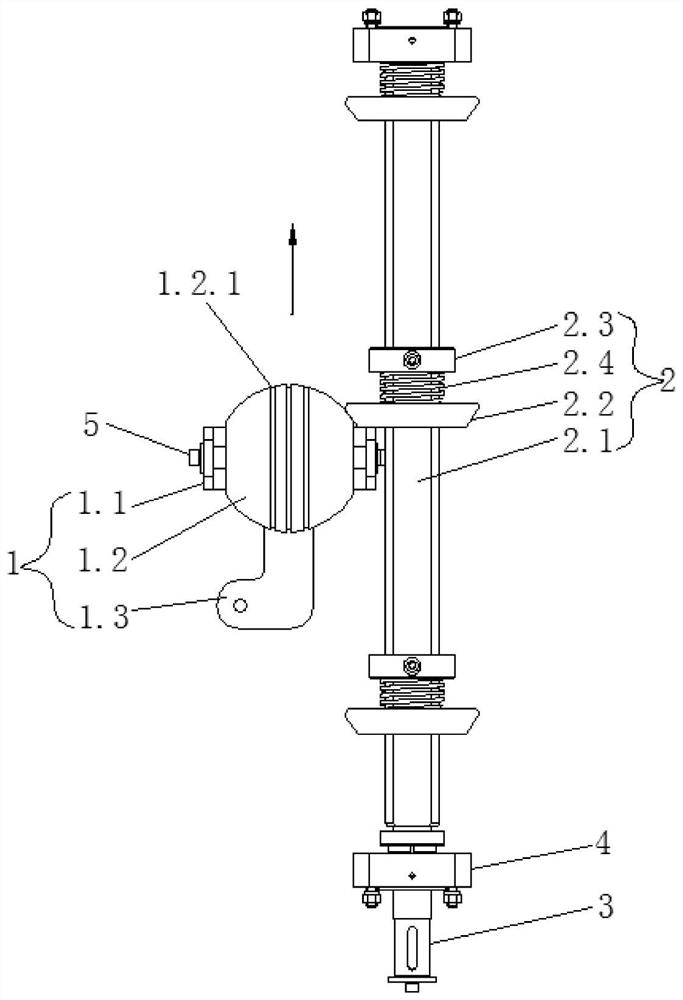

[0030] like Figures 1 to 7 As shown, this embodiment provides a deflection ball conveying mechanism, including a deflection mechanism 1 and a drive mechanism 2. The deflection mechanism 1 includes a support frame 1.1, a deflection ball 1.2 is movably connected to the support frame 1.1, and the deflection ball 1.2 is connected to the bottom of the support frame 1.1. There is a gap between them, the bottom end of the support frame 1.1 is connected with a swing arm 1.3, and the swing arm 1.3 is used to drive the deflection ball 1.2 to deflect as a whole, and the deflection angle is 0-90°. The driving mechanism 2 includes a transmission shaft 2.1, which is sleeved on the transmission shaft 2.1 There is a conical wheel 2.2 always in contact with the deflection ball 1.2, and the conical wheel 2.2 is used to drive the deflection ball 1.2 to rotate.

[0031] In this embodiment, applying a power to the transmission shaft 2.1 to make it rotate can drive the conical wheel 2.2 to rotate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com