Object conveying device for cold chain logistics

A cold chain logistics and conveying device technology, applied in the direction of conveyors, transportation and packaging, refrigerators, etc., can solve problems such as temperature rise, affecting the shelf life of items and normal sales, and achieve the effect of ensuring the quality of transportation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

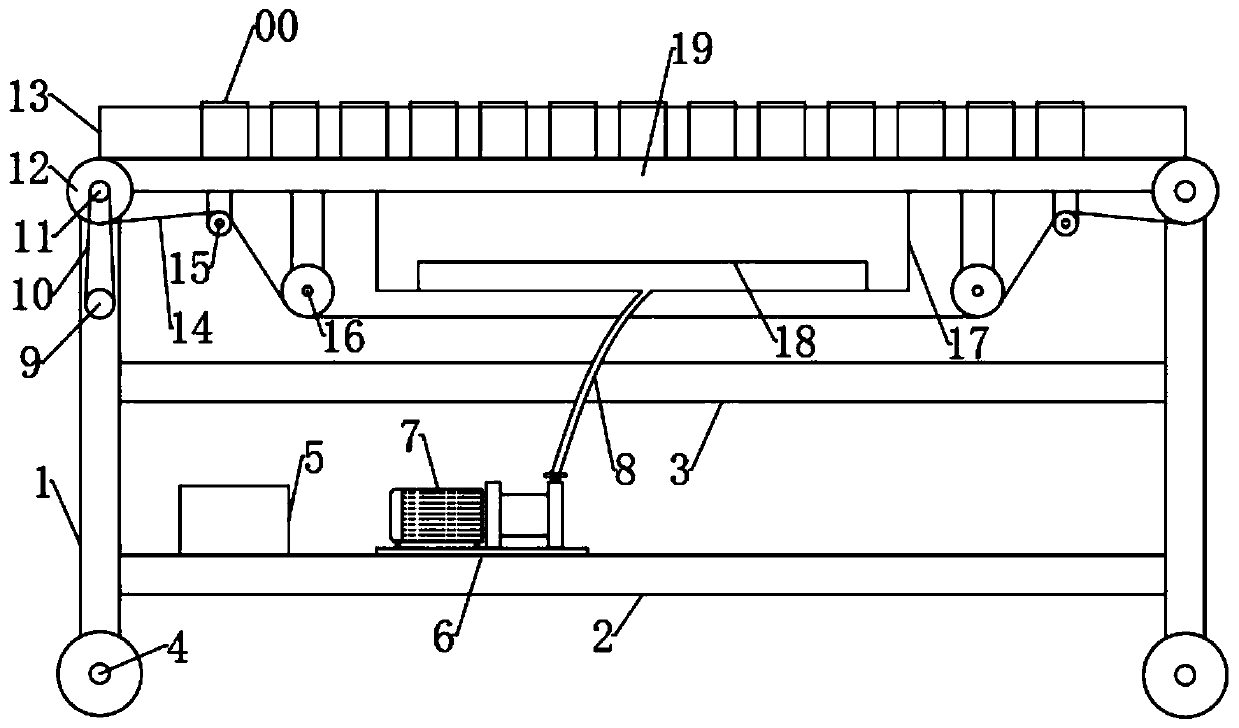

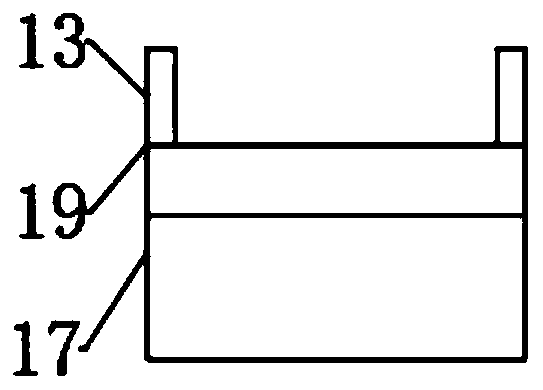

[0020] see Figure 1-2 , an item delivery device for cold chain logistics, comprising a mounting base 2, vertical side plates 1 are connected to both sides of the mounting base 2, a workbench 19 is placed on the side plate 1, and a conveyor belt 14 is arranged on the periphery of the workbench 19 Cargo 00 is placed on the conveyor belt 14, and the bottom of the workbench 19 is equipped with a refrigeration mechanism, so that the workbench 19 maintains a low temperature, avoiding the temperature rise of the cold chain logistics during the transportation process, and affecting the shelf life of the logistics. The specific structure of the refrigeration mechanism is not limited. Preferably, in this embodiment, the refrigeration mechanism includes a refrigeration compressor 5, a refrigeration motor 7 is arranged on one side of the refrigeration compressor 5, and the refrigeration motor 7 is installed on the machine base 6 and communicate with the refrigeration compressor 5 circuit...

Embodiment 2

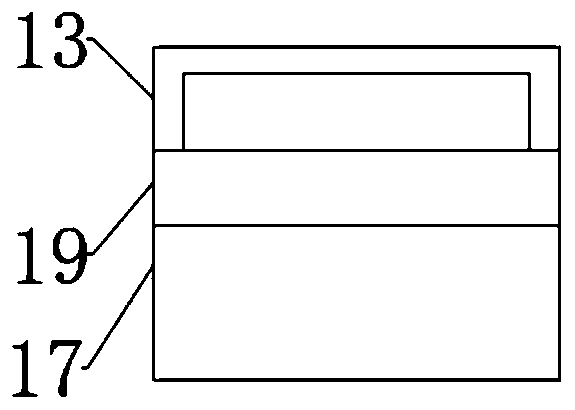

[0030] see image 3 , in Embodiment 1, the guard plate 13 can prevent the cargo 00 from falling on the conveyor belt 14, but the cargo 00 has a large energy loss when it is conveyed on the conveyor belt 14, thereby increasing the working intensity of the refrigeration mechanism, which is not conducive to The prolongation of the service life of the conveying device; therefore, the present embodiment is improved on the basis of Embodiment 1, and the improvement is: the upper end of the guard plate 13 is improved to a closed structure, and the inner wall of the guard plate 13 is provided with a thermal insulation layer, so as to effectively reduce the energy loss when the goods 00 are conveyed on the conveyor belt 14, so that the goods 00 can maintain a better low temperature state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com