Composite electrolytic solution of lithium ion power battery and preparation method thereof

A composite electrolyte and power battery technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of power battery standard requirements and difficult to achieve battery electrical performance, achieve scientific structural design, improve thermal decomposition temperature and Effects of improved flame retardancy, stability and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

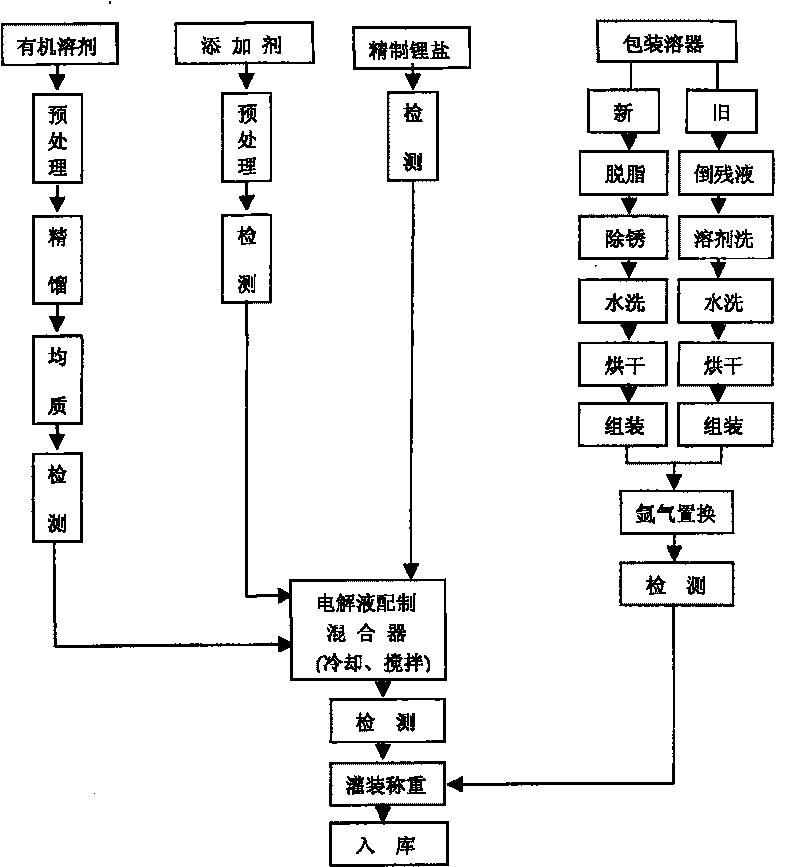

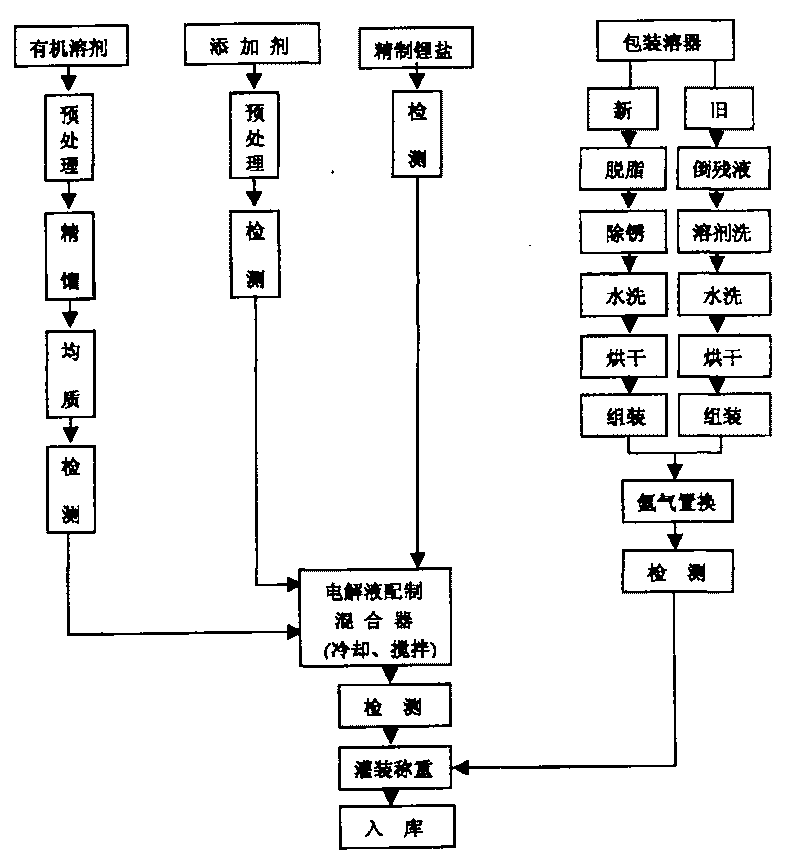

[0019] Below in conjunction with embodiment and accompanying drawing description, the present invention is described in further detail:

[0020] Implementation one:

[0021] The preparation method of the composite electrolyte: (1) After the organic solvent is pretreated, rectified (or dehydrated, alcohol), homogenized, and tested to pass the test, the weight ratio DMC: 23%-45%; EMC: 22%-35%; PC: 5%-15%; EC: 31%-41%; PS: 0.3%-3% injected into the mixer; (2) start the cooling system of the agitator and the mixer while injecting the organic solvent (3) After the refined lithium salt is tested and qualified, the LiPF 6 : 11%-15%; LiBOB: 1.5%-8% added to the mixer; (4) After the additives are pretreated and tested to pass the test, the weight ratio VC: 1%-2%; CHB+BP: 3 %-5%; MFE: 0.1%-0.5%; (CH 3 )SiNHSi(CH 3 ): 3 0.001%-0.00 3 5% is added to the mixer; (5) The stainless steel container for filling the product is cleaned according to different process requirements to meet the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com