Vector mask, vector pump jetting propelling system and underwater aircraft

A pump-jet propulsion and thruster technology, which is applied in ship propulsion, propulsion components, transportation and packaging, etc. It can solve the problems of hull structural vibration, enhance the direct sound of propellers, and reduce the quality of propeller inflow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

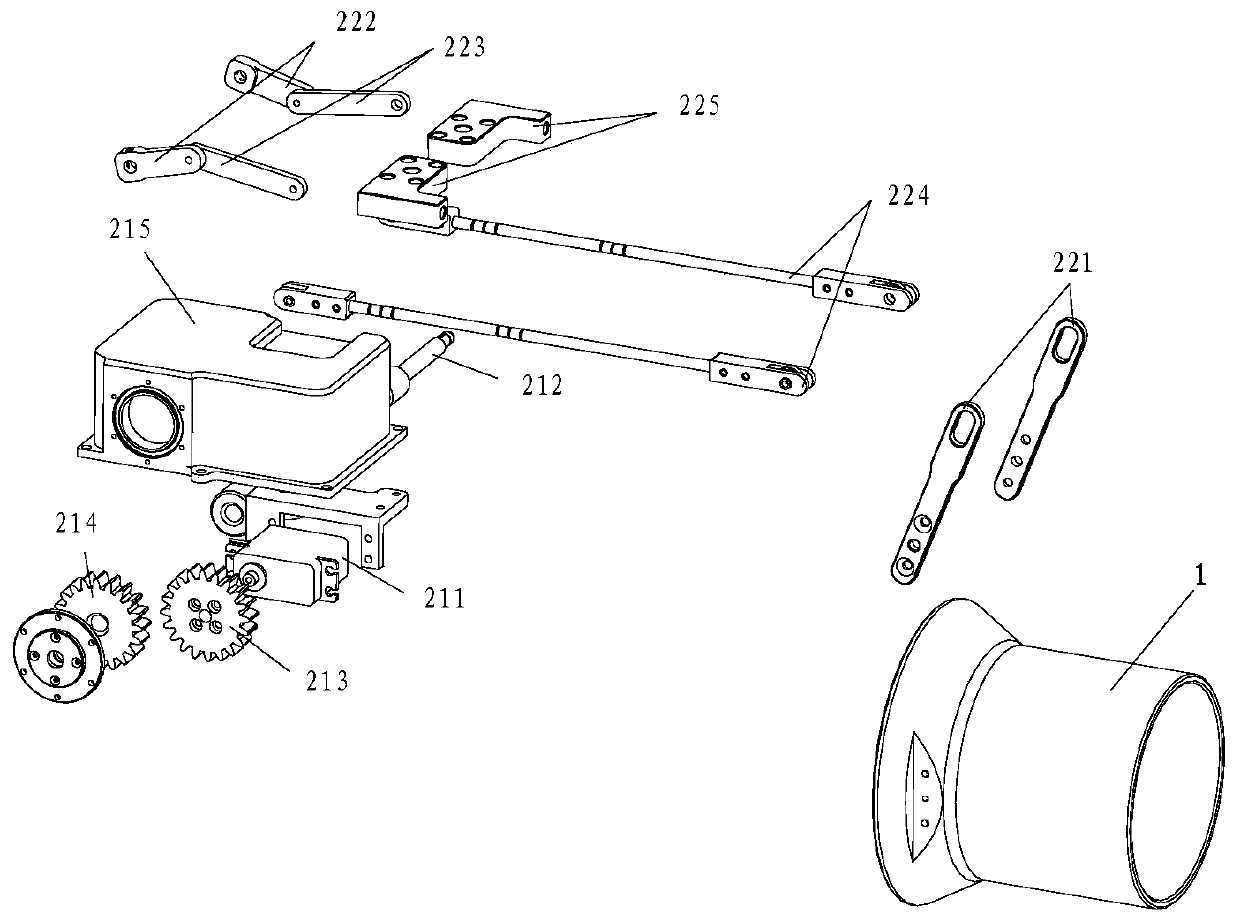

[0031] Such as Figure 1-3 As shown, a vector cover includes a vector cover body 1 and a vector drive mechanism. The vector cover body 1 is used to rotate and be installed on the water outlet end of the vector pump jet propulsion device 3; the vector cover body 1 is provided with a through hole along the axial direction, and the vector The cover body 1 rotates under the drive of the vector drive mechanism until the axis of the through hole and the axis of the outlet end form different angles; wherein, the water flow pushed out from the outlet end is sprayed outward along the through hole.

[0032] The beneficial effect of this embodiment is: the vector cover body 1 is rotated and installed on the water outlet end of the vector pump jet propulsion device 3, and rotates under the drive of the vector drive mechanism until the axis of the through hole and the axis of the water outlet are at different angles, realizing the water outlet from the water outlet. The direction of the wa...

Embodiment 2

[0034] Such as Figure 1-3 As shown, a vector cover includes a vector cover body 1 and a vector drive mechanism. The vector cover body 1 is used to rotate and be installed on the water outlet end of the vector pump jet propulsion device 3; the vector cover body 1 is provided with a through hole along the axial direction, and the vector The cover body 1 rotates under the drive of the vector drive mechanism until the axis of the through hole and the axis of the outlet end form different angles; wherein, the water flow pushed out from the outlet end is sprayed outward along the through hole.

[0035] The vector cover body 1 is rotatably installed on the water outlet of the vector pump spray propulsion device 3, and rotates under the drive of the vector drive mechanism until the axis of the through hole and the axis of the water outlet are at different angles, so that the water flow pushed out from the water outlet goes outward along the through hole The spraying direction and the...

Embodiment 3

[0051] Such as Figure 1-3 As shown, a vector pump jet propulsion system includes a vector pump jet propulsion device 3 and the above-mentioned vector cover, and the vector cover body 1 of the vector cover is rotatably installed at the water outlet of the vector pump jet propulsion device 3 .

[0052] Specifically, the vector pump jet propulsion device 3 includes a propeller 31 and a shroud 32, the water inlet end of the shroud 32 communicates with the water outlet end of the propeller 31, and the water outlet end of the shroud 32 is rotatably mounted with the vector shroud body 1 The propeller 31 pushes the water flow into the air guide cover 32 during work, and the water flow pushed into the air guide cover 32 enters the vector cover body 1 under the guidance of the water guide cover 32, and outwards through the through hole of the vector cover body 1 squirt.

[0053] Specifically, the propeller 31 includes a motor and paddles, the motor drives the paddles to rotate, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com