Automobile wheel brow

A wheel brow and automobile technology, applied in the field of automobile wheel brows, can solve the problems of falling off, loose buckle, loose body and bracket, etc., to ensure the installation effect, avoid abnormal noise, and assemble firmly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

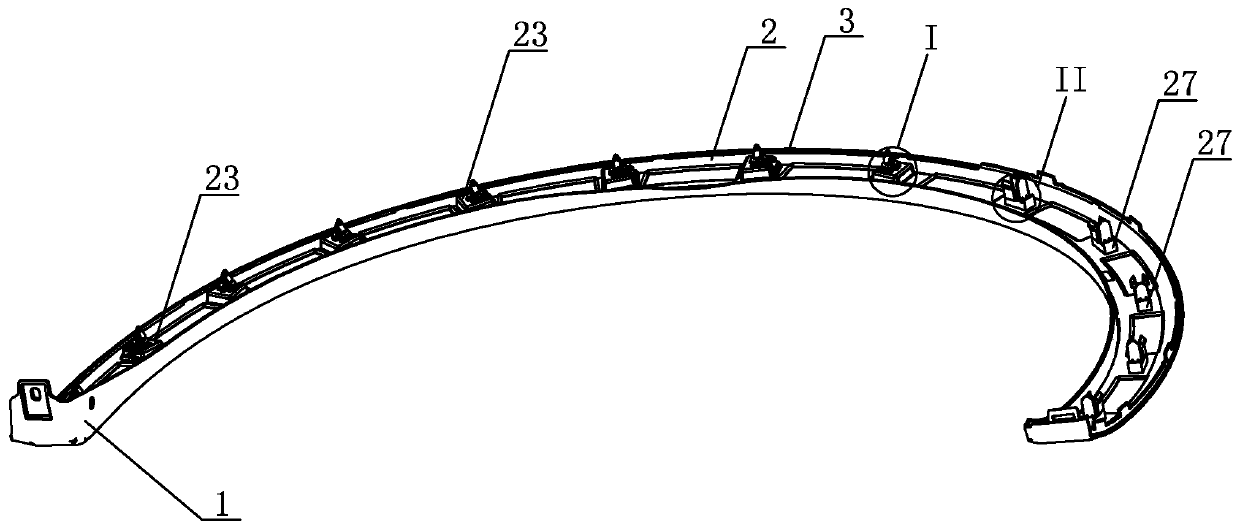

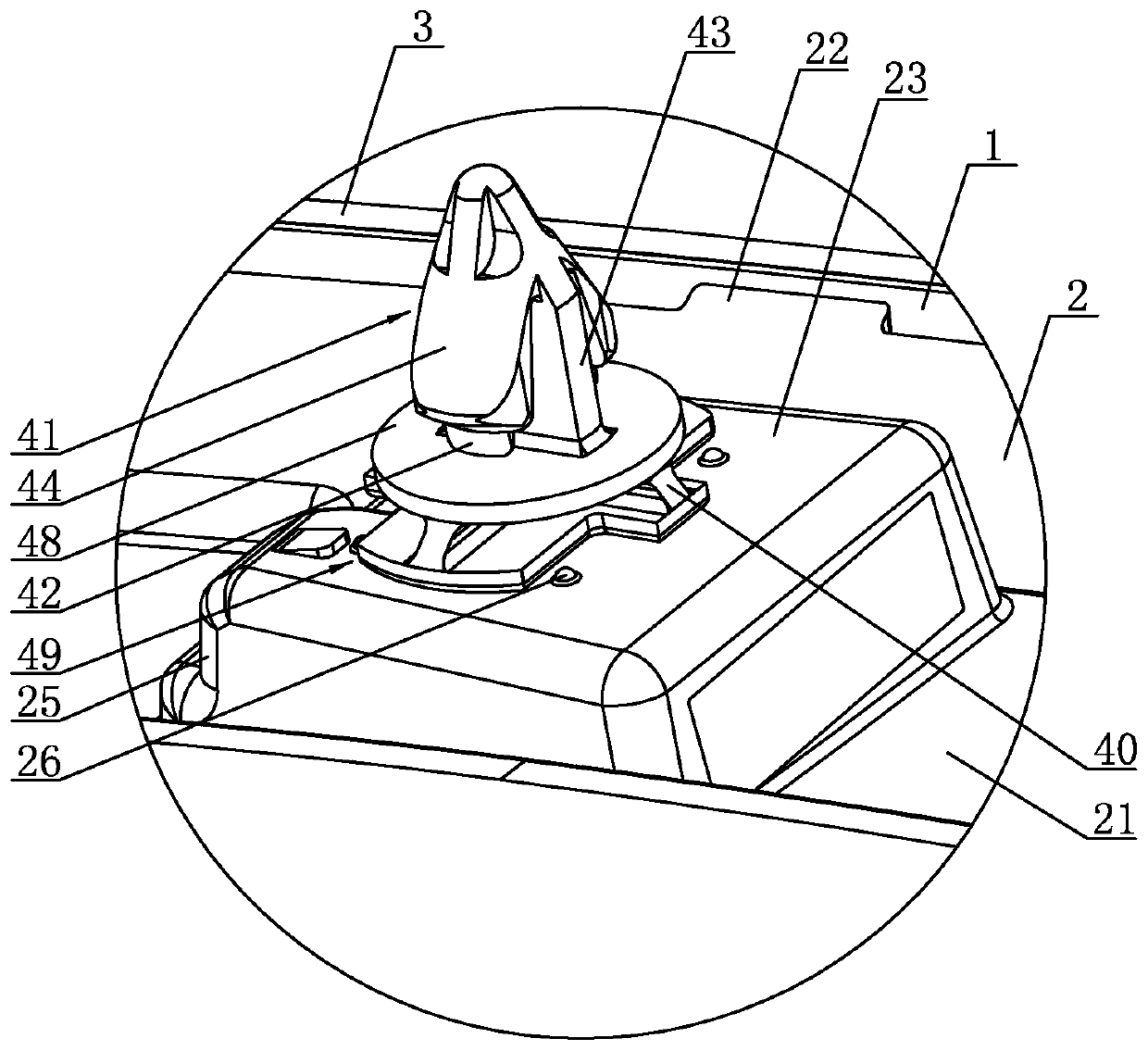

[0030]The automobile wheel eyebrow of embodiment 1, as shown in the figure, includes the wheel eyebrow body 1 and the bracket 2, the wheel eyebrow body 1 and the bracket 2 are made of PP+EPDM-TD30 material, the upper and lower ends of the back of the wheel eyebrow body 1 The protruding ribs 11 and 12 protruding backward are integrally provided, so that a groove 13 is formed on the back of the wheel eyebrow body 1, and 14 bosses 21 protruding toward the wheel eyebrow body 1 are arranged on the bracket 2 at intervals, and 14 bosses 21 The front convex surface of the wheel arch body 1 is attached to the back of the wheel eyebrow body 1 respectively, and the 14 bosses 21 are respectively fixed in the groove 13 on the back of the wheel eyebrow body 1 by ultrasonic welding; the bracket 2 is integrally provided with a plurality of radial positioning blocks 22 at intervals. , the upper end of the back of the wheel eyebrow body 1 is provided with a bevel 14, and an adhesive tape 3 is pa...

Embodiment 2

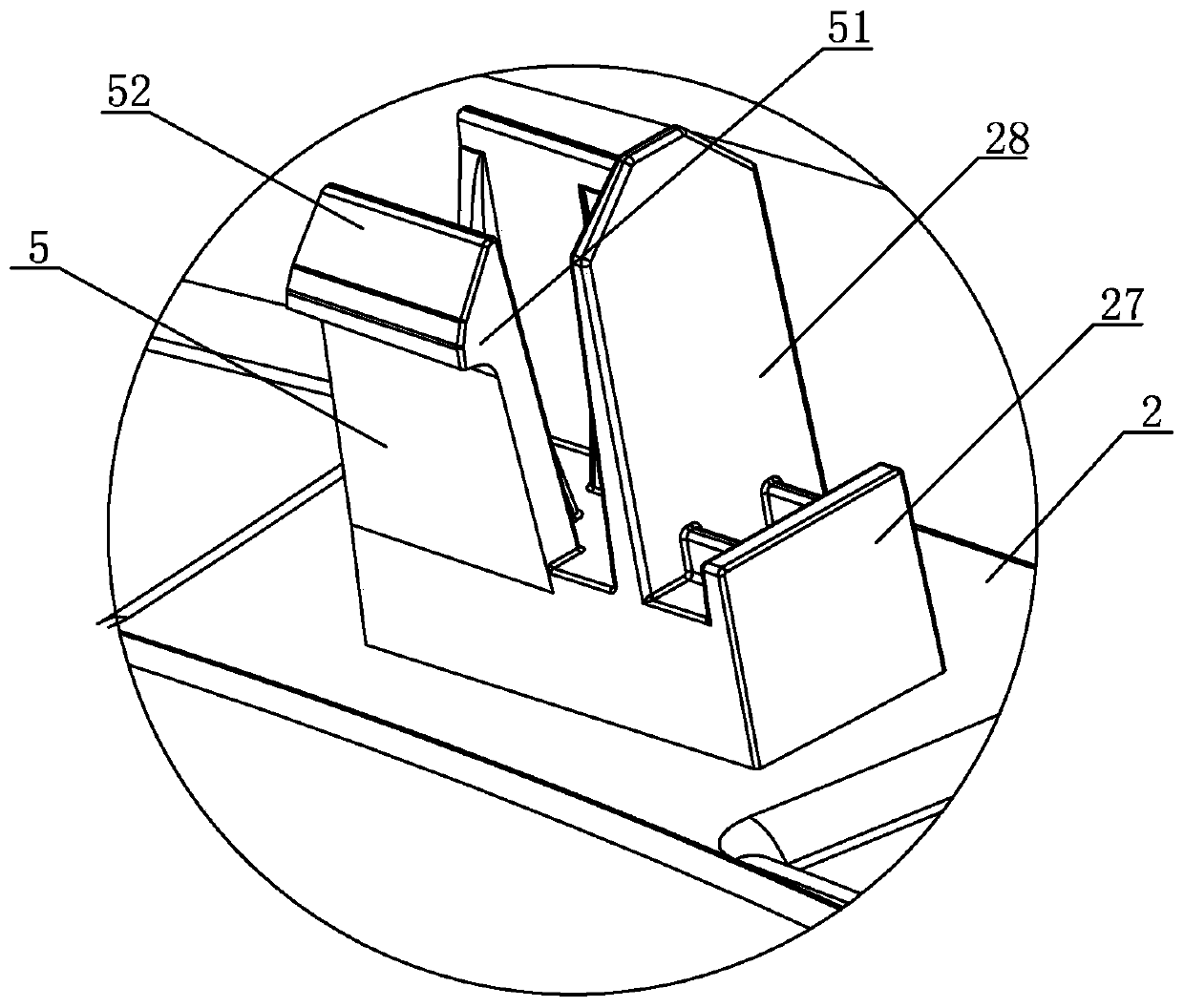

[0033] The difference between the wheel eyebrow of embodiment 2 and embodiment 1 is that, in embodiment 2, the second limiting plate 47 is an arc-shaped plate with upturned sides, and the upper surface of the second limiting plate 47 is aligned with the first limiting plate 47. The minimum distance between the lower surfaces of the bit plates 45 is greater than the wall thickness of the top wall 24 of the first base 23 . After the first buckle is assembled, the first limiting plate 45 and the second limiting plate 47 firmly press against the top wall 24 of the first base 23 to securely install the first buckle on the first base 23 .

Embodiment 3

[0034] The difference between the wheel eyebrow of embodiment 3 and embodiment 2 is that in embodiment 3, the first limiting plate 45 includes an upper plate 48 and a lower plate 49 which are integrally arranged and spaced up and down, and between the upper plate 48 and the lower plate 49 They are connected through several third connecting columns 40 . In this embodiment, the upper plate 48 is a circular plate, the lower plate 49 includes a horizontal plate 491 and a vertical plate 492 which are arranged in a cross in one piece, and four limit platforms are fixed on the upper surface of the top wall 24 of the first base 23 26. After the first buckle is assembled, the four limiting platforms 26 are located at the four corners of the lower plate 49 respectively, and the horizontal plate 491 and the vertical plate 492 are respectively limited longitudinally and laterally by the four limiting platforms 26 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com