Anti-collision device for welding robot

A collision device and welding machine technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as welding torch deformation, affecting welding process quality, increasing equipment maintenance costs, etc., and achieves the effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

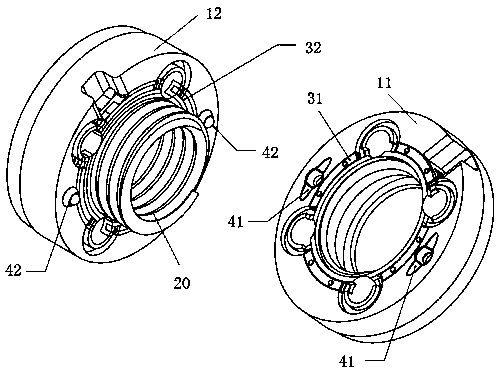

[0017] In order to achieve the purpose of the present invention, as figure 1 As shown, in one of the embodiments of the present invention, a welding robot anti-collision device is provided, including an upper housing 11, a lower housing 12, a connecting spring coil 20, an upper contact reed 31, a lower contact reed 32 and Locate the steel ball 42, connect the axial ends of the spring ring 20 to the axial cavity of the upper housing 11 and the lower housing 12, and the upper contact spring 31 is a ring structure and it is arranged on the upper housing through multiple connection points. On the connecting end surface of the housing 11, the upper contact reed 31 is provided with a contact bump on the surface opposite to the lower contact reed, and the lower contact reed 32 is an annular structure and is fixedly arranged on the connecting end sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com