Open type filter screen of continuous casting secondary cooling water zero section

A secondary cold water, open technology, applied in the direction of fixed filter elements, filtration separation, chemical instruments and methods, etc., can solve the problems of increasing labor intensity of workers, restricting production rhythm, blocking equipment, etc., to prolong normal operation time, The effect of reducing repair costs and avoiding replacement repairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

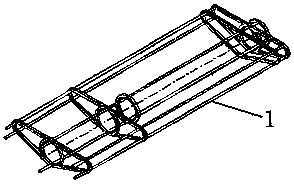

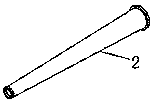

[0027] Refer to attached Figure 1-7 , a continuous casting secondary cooling water zero-section open filter screen, comprising a filter screen skeleton 1, an inlet water filter pipe 2, a filter residue basket 3, an anti-leakage enclosure 4 and a secondary cooling water zero-section cooling pipe 5, the secondary cooling water zero-section The cooling pipe 5 is a flat tube type, one end of the zero-stage cooling pipe 5 of the secondary cooling water is connected to the water inlet pipe 6, the other end of the zero-stage cooling pipe 5 of the secondary cooling water is provided with an end cover 7, and the zero-stage cooling pipe 5 of the secondary cooling water is provided with multiple The water outlet pipe 8 connected with the water nozzle; the shape of the filter screen frame 1 is the same as that of the secondary cooling water zero-stage cooling pipe 5, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com