Production process of cloth-imitating PVC tablecloth

A production process and a cloth-like technology, applied in the field of cloth-like PVC tablecloth and its production technology, can solve the problems of poor wear resistance, flatness, waterproof and oil-proof effect, poor comfort and softness, and difficulty in printing patterns, etc. Exquisite and real, beautiful appearance, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

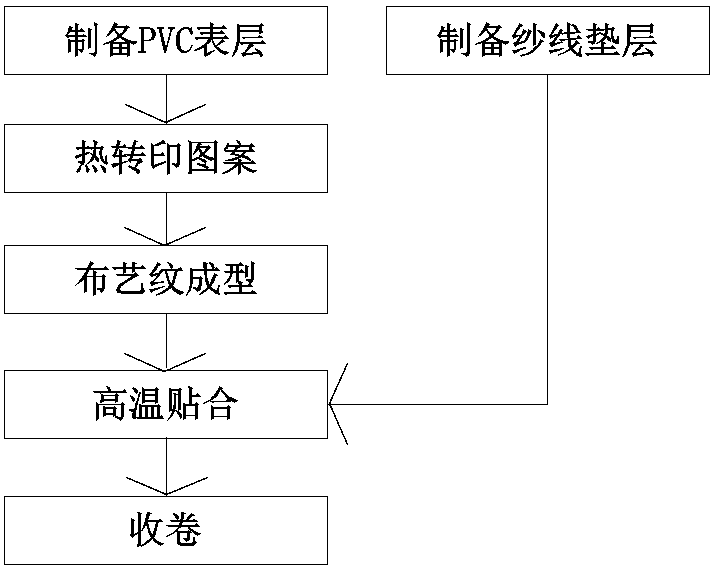

[0028] The production process of fabric-like PVC tablecloth 100 is characterized in that it includes the following steps: S1: making the PVC surface layer; S2: weaving the yarn cushion; S3: adopting heat transfer printing technology to transfer the pattern to the PVC surface layer; S4: passing Fabric pattern forming equipment forms embossing on the surface of PVC, and laminates the surface of PVC and the yarn cushion at high temperature; S5: Winding.

[0029] In S1, when making the PVC surface layer, the raw materials of the PVC surface layer are calculated in parts by mass, including the following components: 60 parts of dioctyl phthalate, 65 parts of PVC resin powder, 72 parts of active calcium, 2.92 parts of heat stabilizer, 0.02 parts of pigment powder, 0.04 parts of titanium dioxide, 0.02 parts of UV protection, fading and anti-discoloration additives. The heat stabilizer is selected from calcium-zinc composite stabilizers, and the gram weight of the active calcium is 200g...

Embodiment 2

[0037] The production process of fabric imitation PVC tablecloth is characterized in that it includes the following steps: S1: making PVC surface layer; S2: weaving yarn cushion; S3: adopting heat transfer printing process to transfer pattern to PVC surface layer; S4: using fabric art The pattern forming equipment forms embossing on the PVC surface, and the PVC surface and the yarn cushion are laminated at high temperature; S5: Winding.

[0038] In S1, when making the PVC surface layer, the raw materials of the PVC surface layer are calculated in parts by mass, including the following components: 58 parts of dioctyl phthalate, 47 parts of PVC resin powder, 92 parts of active calcium, 2.92 parts of heat stabilizer, 0.02 parts of pigment powder, 0.04 parts of titanium dioxide, 0.02 parts of UV protection, fading and anti-discoloration additives. The heat stabilizer is selected from calcium-zinc composite stabilizers, and the gram weight of the active calcium is 200g / ㎡; in S1, PVC...

Embodiment 3

[0045] The production process of fabric imitation PVC tablecloth is characterized in that it includes the following steps: S1: making PVC surface layer; S2: weaving yarn cushion; S3: adopting heat transfer printing process to transfer pattern to PVC surface layer; S4: using fabric art The pattern forming equipment forms embossing on the PVC surface, and the PVC surface and the yarn cushion are laminated at high temperature; S5: Winding.

[0046] In S1, when making the PVC surface layer, the raw materials of the PVC surface layer are calculated in parts by mass, including the following components: 58 parts of dioctyl phthalate, 47 parts of PVC resin powder, 92 parts of active calcium, 2.92 parts of heat stabilizer, 0.02 parts of pigment powder, 0.04 parts of titanium dioxide, 0.02 parts of UV protection, fading and anti-discoloration additives. The heat stabilizer is selected from calcium-zinc composite stabilizers, and the gram weight of the active calcium is 200g / ㎡; in S1, PVC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com