Moxa floss quilt

A quilt and moxa velvet technology, applied in the textile field, can solve problems such as insufficient health care functions, achieve good antibacterial function, enhance resistance, and purify the air.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

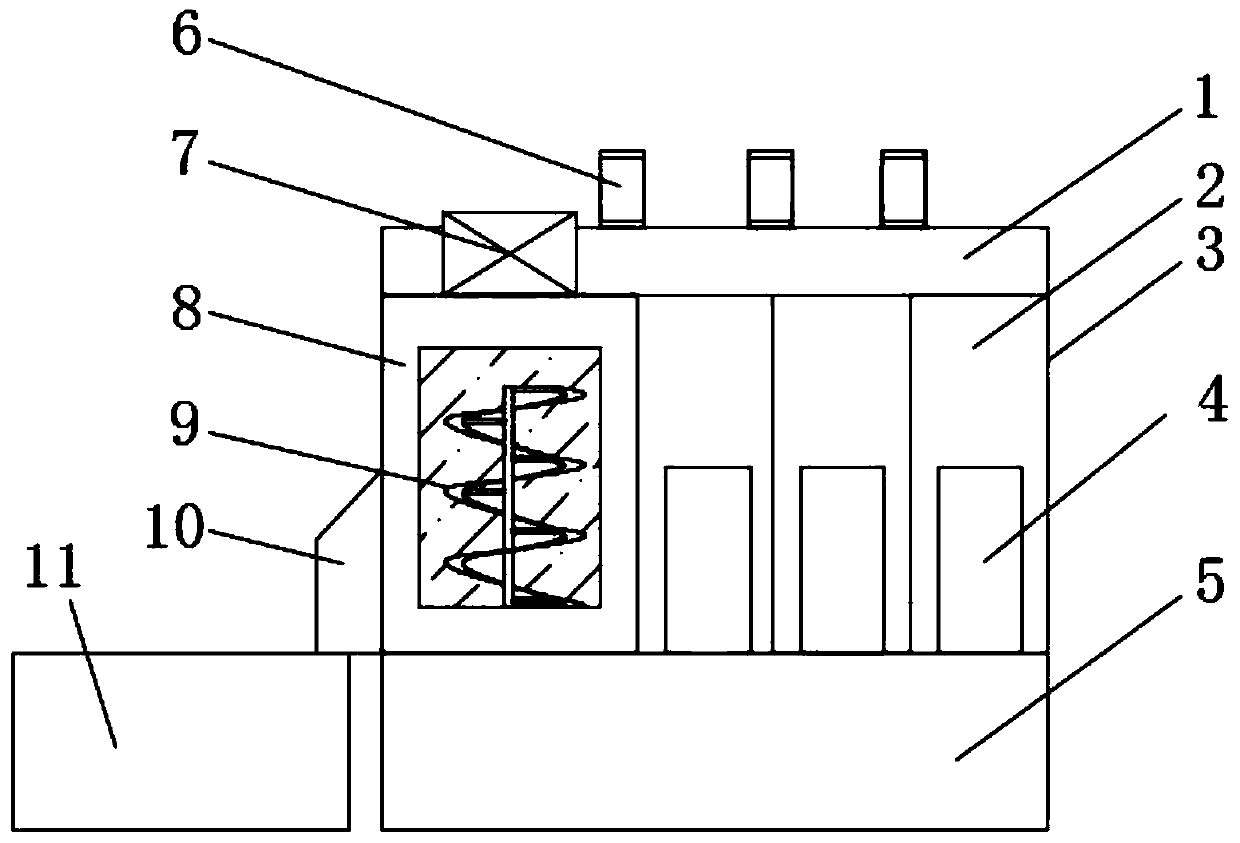

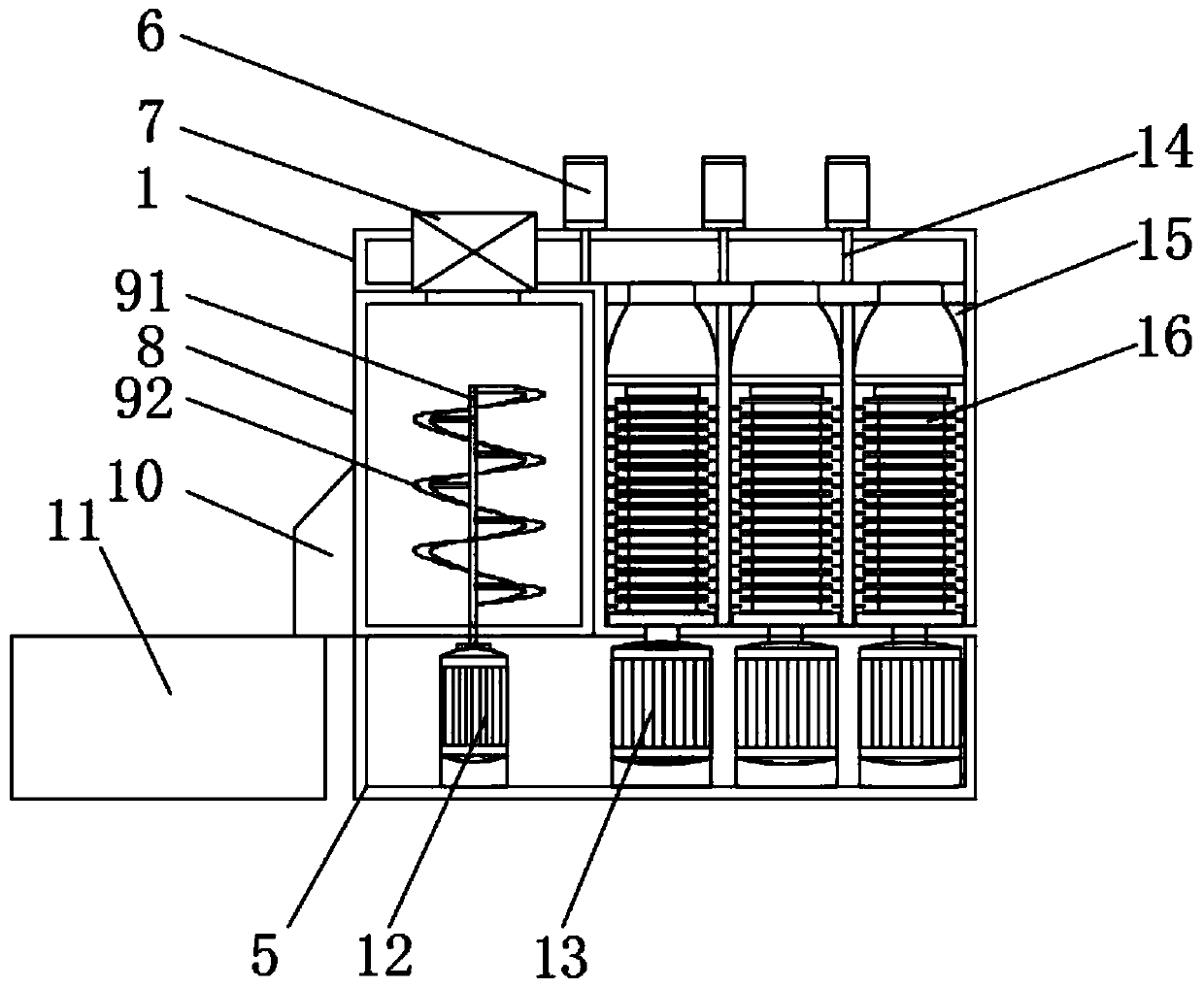

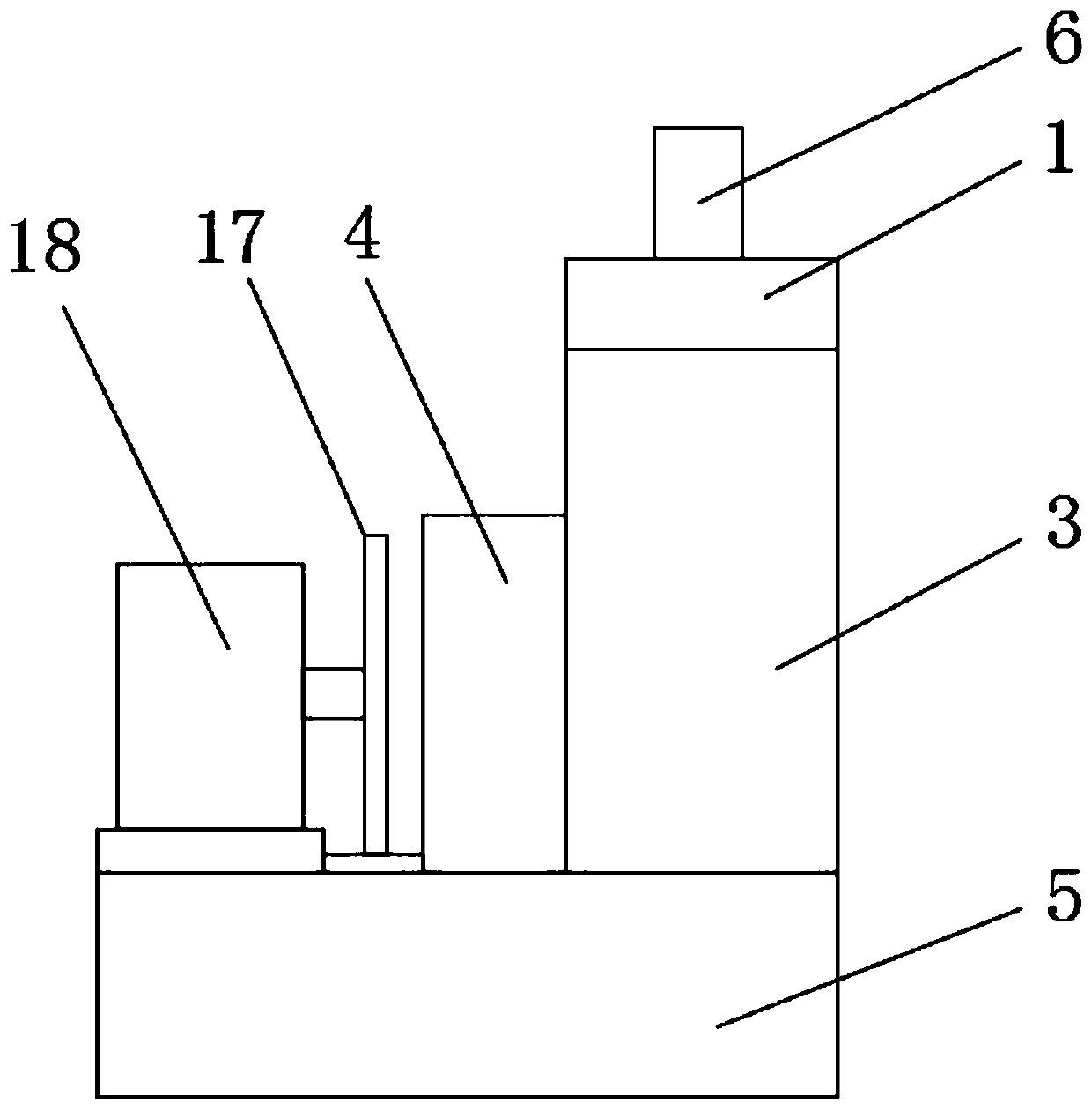

[0044] see Figure 1-5 As shown, this embodiment is a moxa quilt, including a quilt shell and a quilt core for filling the quilt shell. The quilt shell is woven from spinning threads, and the spinning threads are soaked in the liquid mixture for 5-10 minutes before being woven into the quilt shell. , the quilt core is made of cotton wool, polyester fiber and moxa in a weight ratio of 5:3:1;

[0045] The liquid mixture includes the following substances in parts by weight: 40 parts of wormwood extract, 30 parts of water-based adhesive, 1 part of fresh flower extract, 0.1 part of defoamer, 0.5 part of surfactant, and 45 parts of water;

[0046] This moxa quilt is prepared by the following steps:

[0047] Step 1: Prepare the liquid mixture: take fresh wormwood stems and leaves, mash them, add water to extract, filter and remove impurities, and obtain the wormwood extract, add water-based adhesive, defoamer, surface The active agent and water are stirred evenly, and then the fres...

Embodiment 2

[0061] see Figure 1-5 As shown, this embodiment is a moxa quilt, including a quilt shell and a quilt core for filling the quilt shell. The quilt shell is woven from spinning threads, and the spinning threads are soaked in the liquid mixture for 5-10 minutes before being woven into the quilt shell. , the quilt core is made of cotton wool, polyester fiber and moxa in a weight ratio of 5:3:3;

[0062] The liquid mixture includes the following substances in parts by weight: 50 parts of wormwood extract, 35 parts of water-based adhesive, 1 part of fresh flower extract, 0.2 part of defoamer, 1.0 part of surfactant, and 50 parts of water;

[0063] This moxa quilt is prepared by the following steps:

[0064] Step 1: Prepare the liquid mixture: take fresh wormwood stems and leaves, mash them, add water to extract, filter and remove impurities, and obtain the wormwood extract, add water-based adhesive, defoamer, surface The active agent and water are stirred evenly, and then the fres...

Embodiment 3

[0078] see Figure 1-5 As shown, this embodiment is a moxa quilt, including a quilt shell and a quilt core for filling the quilt shell. The quilt shell is woven from spinning threads, and the spinning threads are soaked in the liquid mixture for 5-10 minutes before being woven into the quilt shell. , the quilt core is made of cotton wool, polyester fiber and moxa in a weight ratio of 5:3:5;

[0079] The liquid mixture includes the following substances in parts by weight: 40-60 parts of wormwood extract, 40 parts of water-based adhesive, 2 parts of fresh flower extract, 0.3 part of defoamer, 1.5 parts of surfactant, and 55 parts of water;

[0080] This moxa quilt is prepared by the following steps:

[0081] Step 1: Prepare the liquid mixture: take fresh wormwood stems and leaves, mash them, add water to extract, filter and remove impurities, and obtain the wormwood extract, add water-based adhesive, defoamer, surface The active agent and water are stirred evenly, and then the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com