Optical thin film, structural color pigment and preparation method of optical thin film

An optical film, structural color technology, applied in optics, optical components, fibrous fillers, etc., can solve the problem of low brightness, and achieve the effect of improving brightness and color vividness, diverse structures, and bright colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

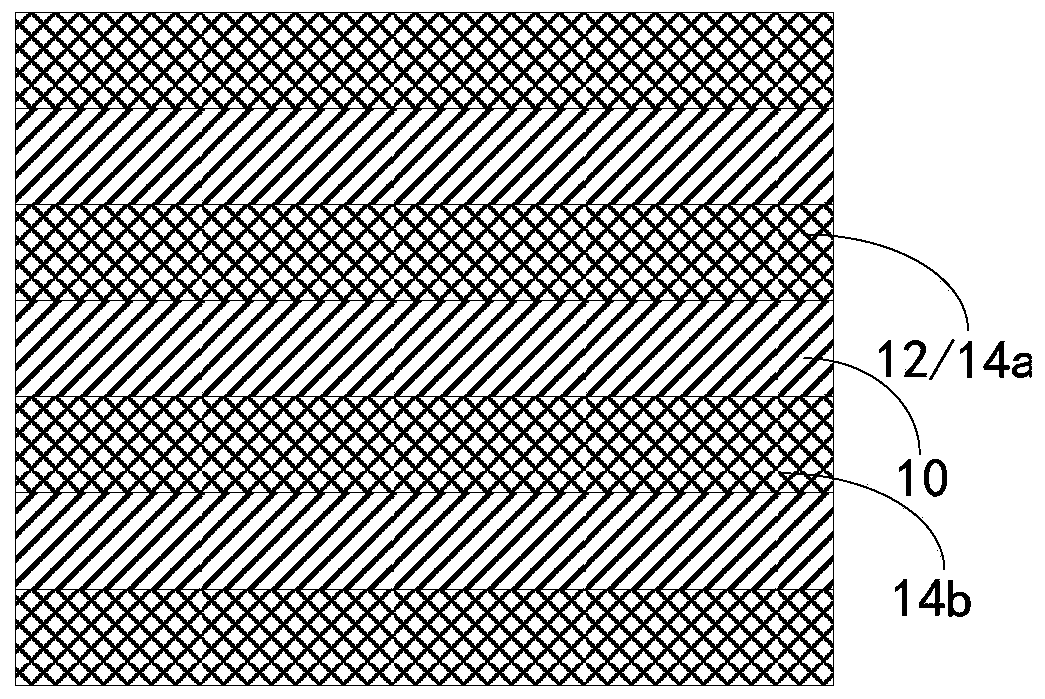

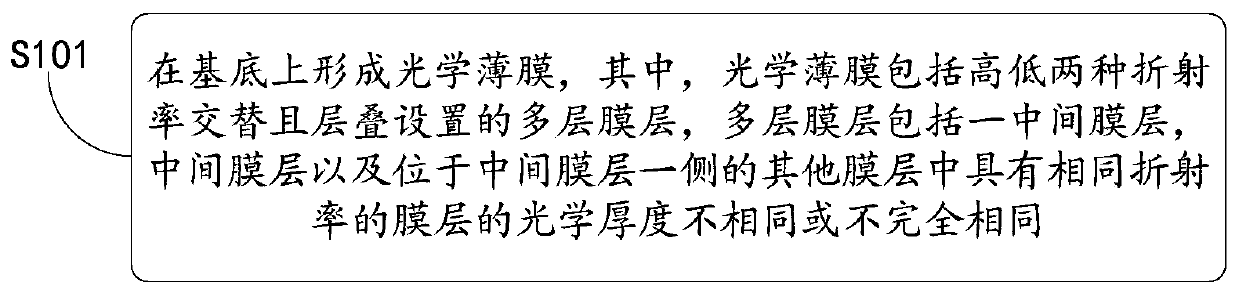

[0037] Please also refer to figure 1 with figure 2 , figure 2 It is a schematic flow chart of an embodiment of the preparation method of the optical thin film of the present application, the preparation method comprising:

[0038] S101: Form an optical thin film on the substrate, wherein the optical thin film includes multi-layer layers with alternate high and low refractive indices and stacked layers, the multi-layer layer includes an intermediate film layer 10; the intermediate film layer 10 and the intermediate film layer 10 Among the other film layers 12 on one side, the optical thicknesses of the film layers with the same refractive index are different or not completely the same.

[0039] Specifically, the substrate may be a transparent glass substrate, polyethylene hard plastic, or the like. In addition, the above-mentioned step S101 can be implemented in the following manner: sequentially forming multi-layered film layers on the substrate by means of vacuum evapora...

Embodiment 1

[0044] The optical film consists of 7 layers, and the corresponding optical thickness and material of each layer are shown in Table 1 below. Among them, the material of the low refractive index film layer is SiO 2 , the material of the high refractive index film layer is TiO 2 ,.

[0045] First, the color coordinates of the optical film obtained through the detection of a color analyzer are: x:0.15, y:0.13, which indicate that the optical film is a blue optical film.

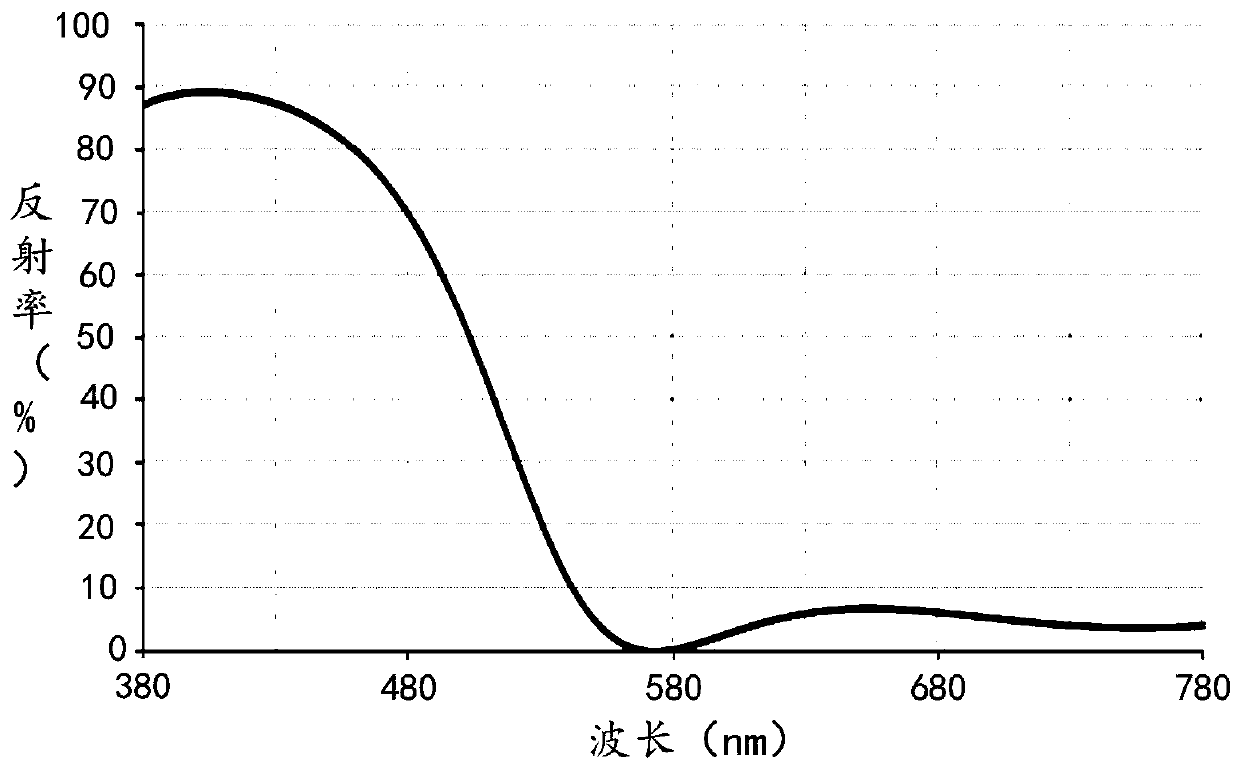

[0046] Secondly, the spectroscopic curve of this optical thin film is obtained by spectrometer detection, such as image 3 as shown, image 3 It is a schematic diagram of the spectroscopic spectrum curve of the optical thin film in Example 1. It can be seen from the figure that the maximum reflection wavelength is around 400nm, indicating that the optical film is a blue optical film, and the maximum reflectance is close to 90%.

[0047] Table 1: Material and optical thickness of each layer of optical film ...

Embodiment 2

[0050] The optical film consists of 7 film layers, and the corresponding optical thickness and material of each layer are shown in Table 2 below. Among them, the material of the low refractive index film layer is SiO 2 , the material of the high refractive index film layer is TiO 2 .

[0051] First, the color coordinates of the optical film obtained through the detection of a color analyzer are: x:0.23, y:0.49, which indicate that the optical film is a green optical film.

[0052] Secondly, the spectroscopic curve of this optical thin film is obtained by spectrometer detection, such as Figure 4 as shown, Figure 4 It is a schematic diagram of the spectroscopic spectrum curve of the optical thin film in Example 2. It can be seen from the figure that the maximum reflection wavelength is around 530nm, indicating that the optical film is a green optical film; and the maximum reflectance is close to 90%.

[0053] Table 2: Material and optical thickness of each layer of optica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com