Directional valve with self-compensating directional cock

A self-compensating, reversing valve technology, applied in the field of reversing valves, can solve the problems of unguaranteed sealing performance and wear of sealing materials, and achieve the effect of maintaining smoothness, good stress state, and improving long-term life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

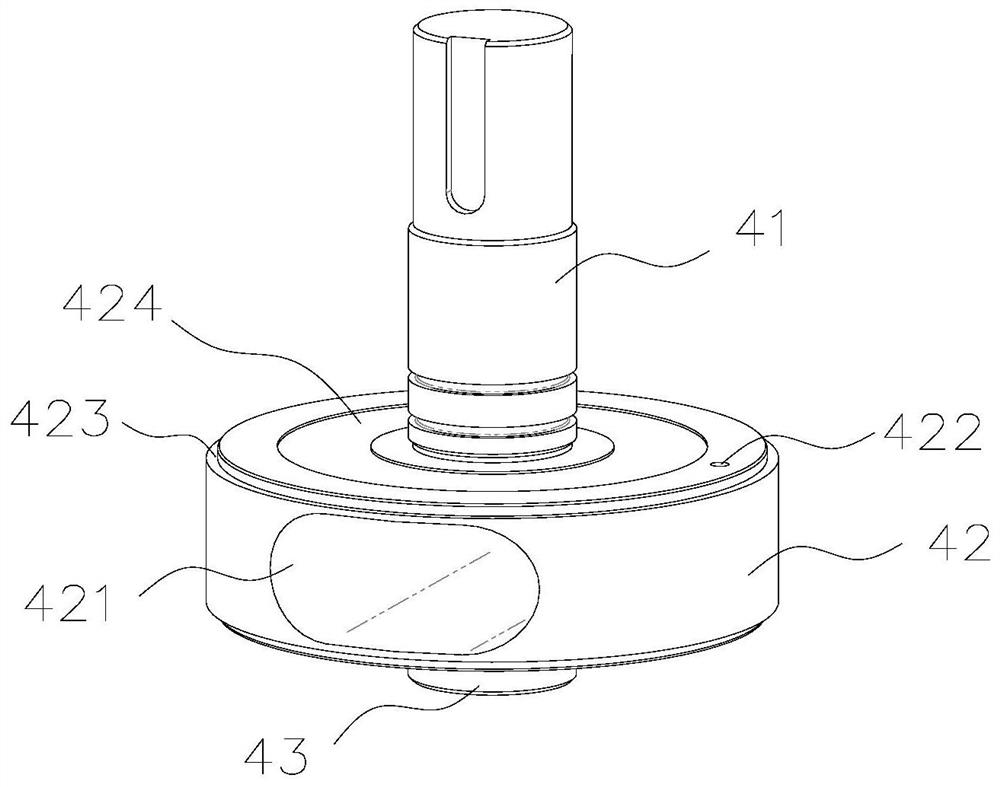

[0047] The channel barrel is divided into only two barrel sections along the fluid flow direction, namely the first barrel section and the second barrel section. The first elastic member 44 is a metal bellows, located between the first barrel section and the second barrel section, and the number of the first elastic member 44 is equal to the number of flow channels. The first elastic member 44 is respectively welded to the first cylinder section and the second cylinder section on both sides, and ensures that the corresponding flow channels are aligned and connected.

Embodiment 2

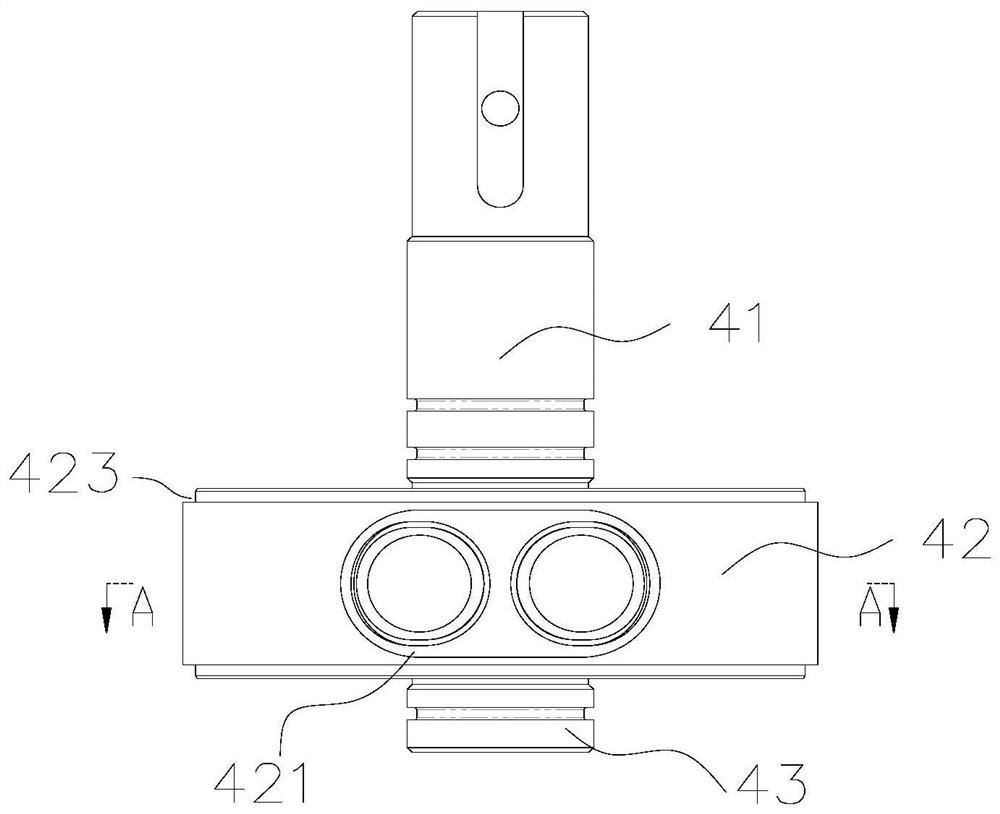

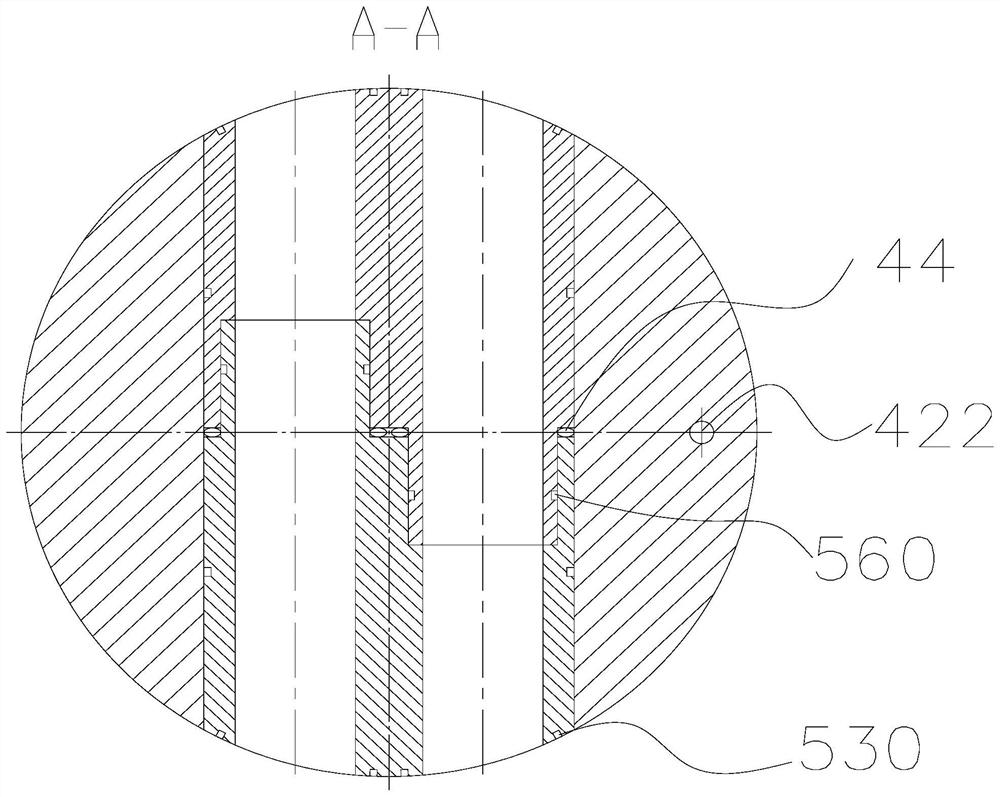

[0049] Each flow channel in the first barrel section 54 and the second barrel section 59 is connected by socketing, and the socketing forms a socket section, and first sealing ring grooves 56 are arranged at two opposite socket surfaces of the socket section. , a first sealing ring 560 is disposed in the first sealing ring groove 56 .

[0050] Socketing methods include the following methods:

[0051] The first is: if Figure 4 As shown, on the side of the first cylinder section 54 and the second cylinder section 59 close to the first elastic member 44, each flow channel is provided with an annular groove 58 or a protrusion 57, and the parallel flow of the protrusion 57 is set. An annular groove 58 is arranged on the adjacent flow channel of the channel, and it is ensured that any flow channel in the first barrel section 54 and the second barrel section 59 is matched and sleeved in the annular groove 58 by the protrusion 57 to form a sleeve section. Specifically, in this solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com