Prefabricated assembly type pool guide wall

A prefabricated assembly and diversion wall technology, applied in waterway systems, water supply devices, drainage structures, etc., can solve the problems of poor surface flatness control, difficult construction, and long construction period, so as to speed up construction progress and improve construction. The effect of quality, good suitability and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The "a prefabricated pool diversion wall" proposed by the present invention will be further described in detail below with reference to the drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

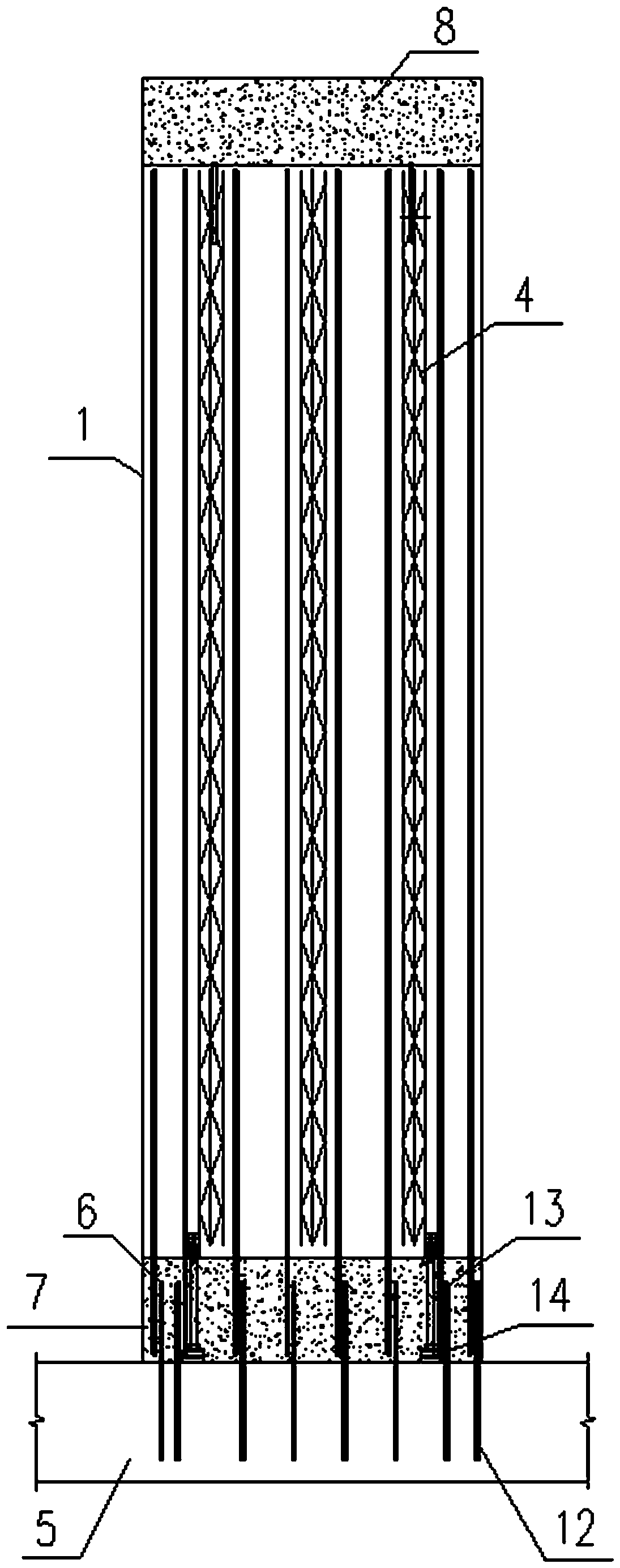

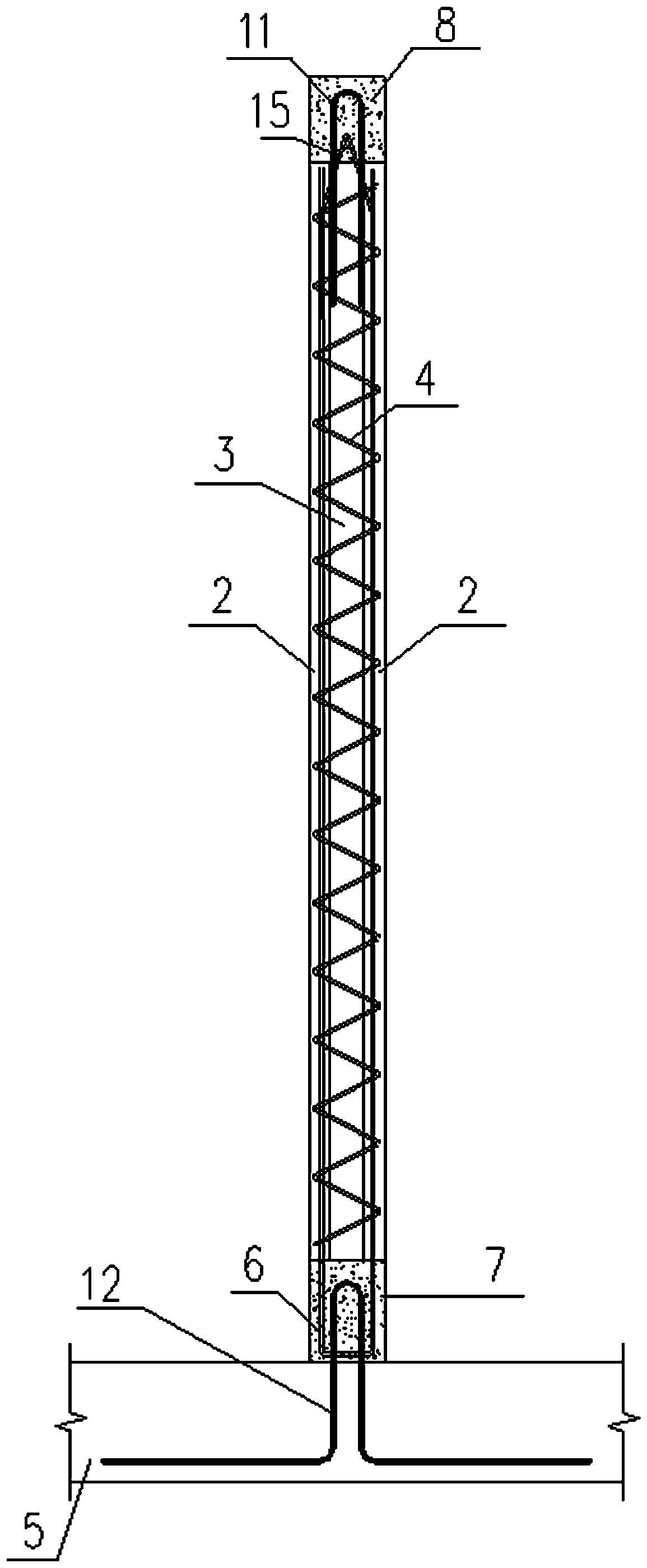

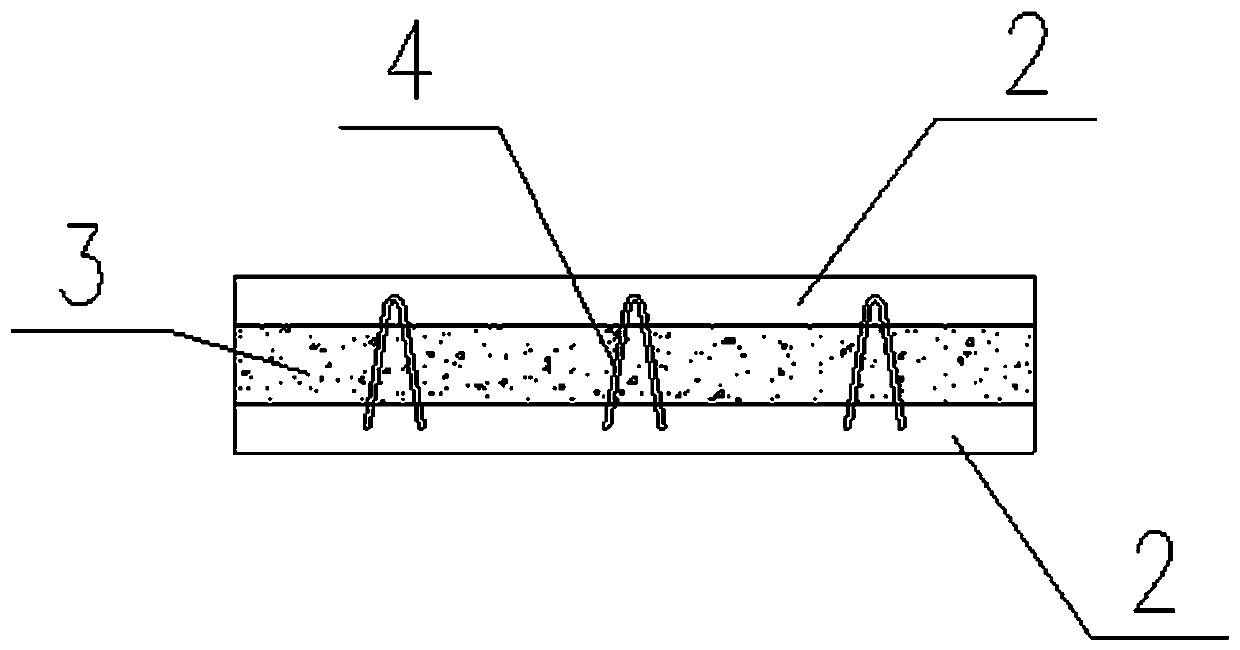

[0018] Please refer to Figure 1~4 , this embodiment discloses a prefabricated assembly type diversion wall, including a prefabricated reinforced concrete diversion wall 1, the laminated plate is composed of a prefabricated plate 2, a post-cast layer 3, and a truss bar 4, and is placed on the bottom plate of the pool 5, and the wall is vertically The ribs are made at the bottom of the wall to form a U-shaped structure 6 at the bottom of the wall and the bottom plate 2 is con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com