A kind of aging-resistant penetrating asphalt regenerant and its preparation method

An asphalt rejuvenator and permeable technology, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of poor permeability, unsatisfactory regeneration effect, poor thermal stability and aging resistance, etc., and achieve improved penetration Effect, reduction of adverse effects, effect of safety performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

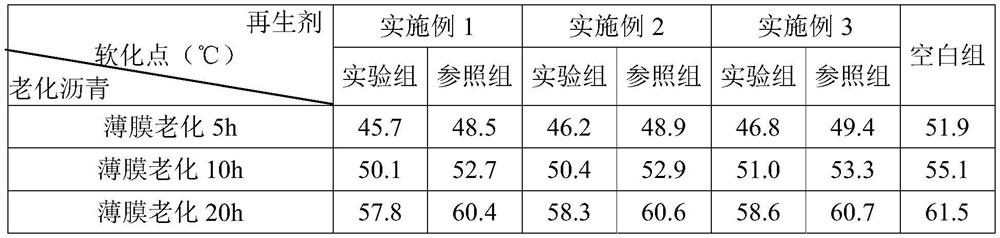

Examples

preparation example Construction

[0021] A preparation method of aging-resistant penetrating asphalt regenerant, comprising the following steps:

[0022] Step 1: Add the base oil into the reaction vessel, add the compatibilizer at 110°C-130°C and stir at 300r / min-400r / min for 20min-30min to preliminarily prepare the mother liquor of the regenerant;

[0023] Step 2: Increase the temperature to 120°C-130°C, add anti-aging agent, and stir at a constant temperature of 800r / min-1000r / min for 45min-60r / min;

[0024] Step 3: Lower the temperature of the solution to 80°C to 95°C, then add a wetting agent and a penetrant to the reaction vessel, stir at a constant temperature of 200r / min to 300r / min for 15 to 20 minutes, and stand to cool to obtain Anti-aging penetrating asphalt regenerant.

Embodiment 1

[0027] According to the number of parts by mass, 80 parts of base oil prepared by catalytic cracking oil slurry and residual oil at a ratio of 2:1 were added to a three-necked flask, and then 8 parts of base oil obtained by compounding sulfonate and maleic anhydride were taken. Add the compatibilizer to the base oil, and stir for 20 minutes at a rate of 300r / min. During the stirring process, the temperature is controlled at 110°C; Stir at 200r / min for 45min; then lower the temperature of the mixed solution to 80°C, add 0.5 parts of alkylphenol polyoxyethylene ether and 3 parts of fatty alcohol polyoxyethylene ether into the reaction vessel, stir at 200r / min for 15min, then statically After cooling, the anti-aging penetrating asphalt regenerant can be obtained.

Embodiment 2

[0029] According to the number of parts by mass, 88 parts of base oil prepared by catalytic cracking oil slurry and residual oil at a ratio of 2:1 were added to a three-necked flask, and 10 parts of base oil obtained by compounding sulfonate and maleic anhydride were taken. Add the compatibilizer to the base oil, and stir for 25 minutes at a rate of 350r / min. During the stirring process, the temperature is controlled at 120°C; Stir for 53min at 250r / min; then lower the temperature of the mixed solution to 88°C, add 0.8 parts of alkylphenol polyoxyethylene ether and 4 parts of fatty alcohol polyoxyethylene ether into the reaction vessel, stir at 250r / min for 18min, then let it stand After cooling, the aging-resistant penetrating asphalt regenerant can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com