Applicable method of mold application for integral molding of satellite scanning mirror mounting frame

A technology for scanning mirrors and mounting frames, applied in applications, frames, home appliances, etc., can solve the problems of a single mounting frame structure, the inability to effectively locate the reinforcing ribs, and the inability to compact the pressure gradient structure, so as to improve the positioning accuracy and The degree of compaction, reducing the difficulty of moulding, and increasing the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

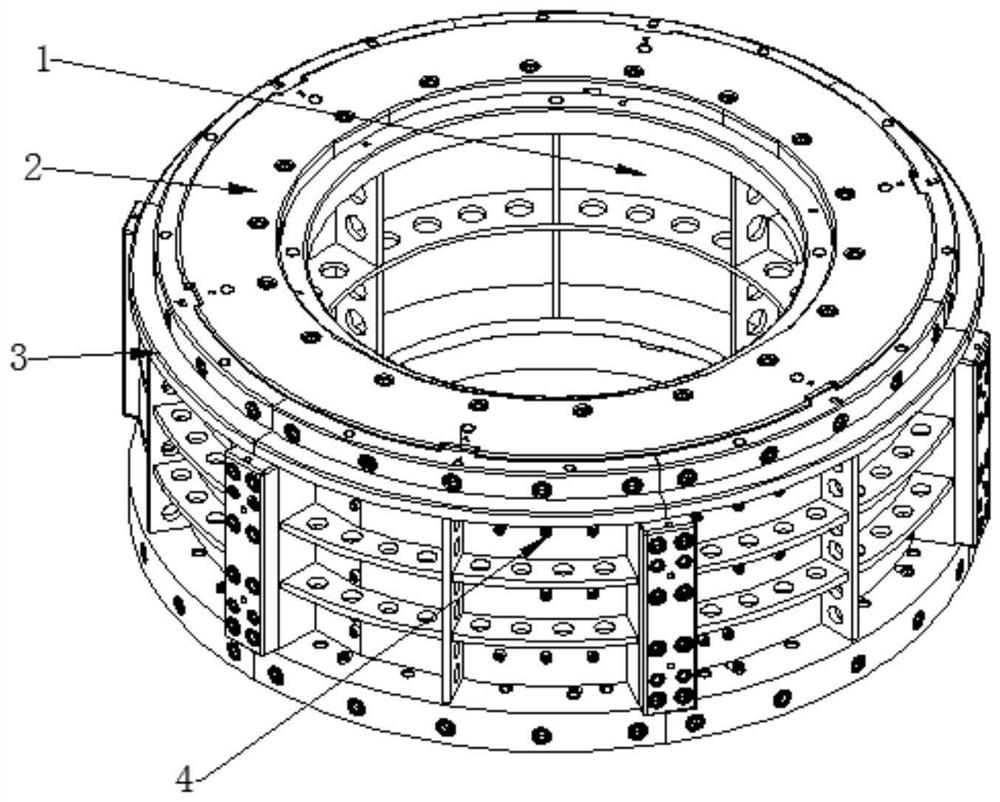

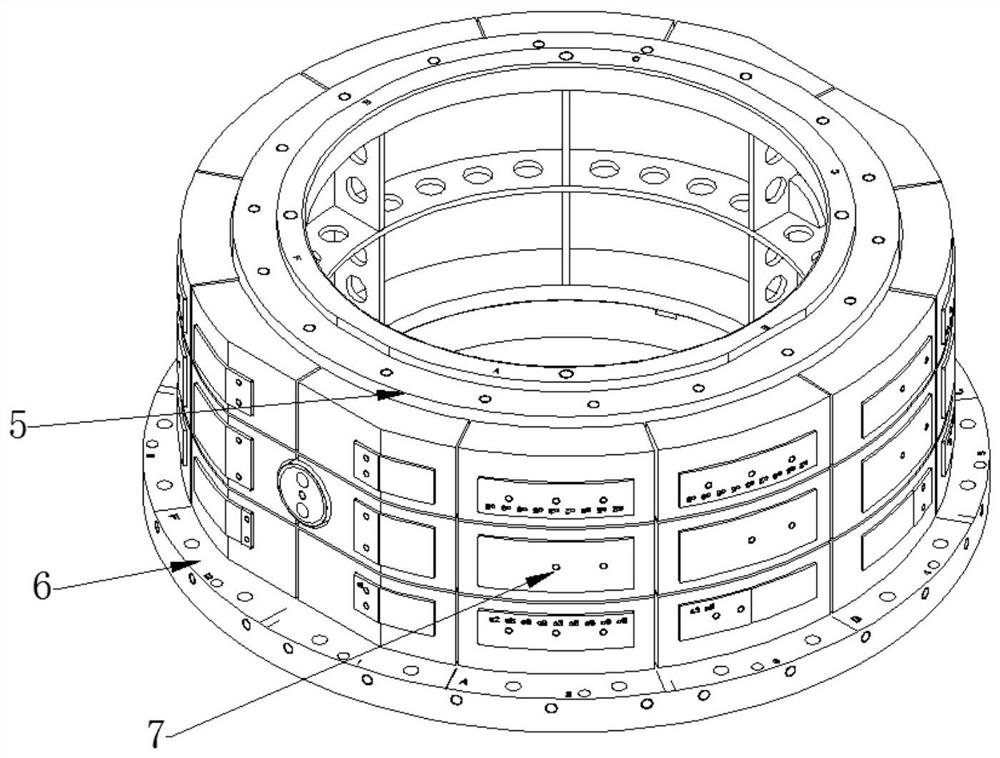

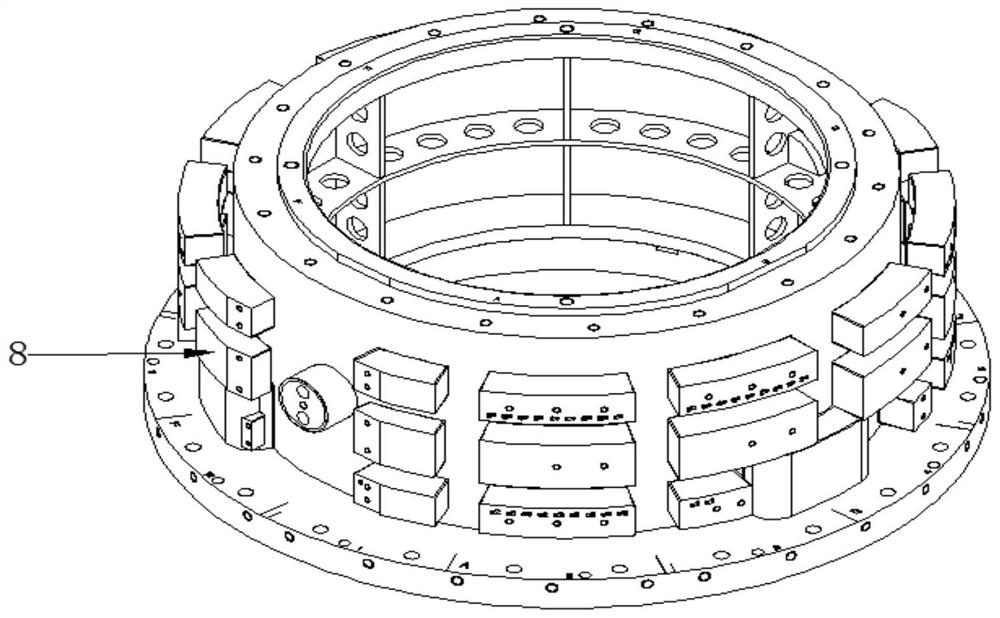

[0064] Taking an overall one-time molding satellite scanning mirror installation frame mold as an example, see the attached figure 1 , 2 , 3, 4, the mold includes 1, profile 2, filling material 3, filling material positioning device 4.

[0065] 1. Mold material selection

[0066] S1. The mold is integrally welded with Q235.

[0067] 2. Mold design

[0068] S2. Determine the molding reference plane, and then determine the remaining molding surfaces through optimization to ensure a stable and reliable closed mold structure with molding quality.

[0069] S3. Design the inner silicone rubber according to the inner cavity structure, and keep the silicone rubber expansion blank scoring line and the steel core positioning hole on the closed mold.

[0070] S4. Design the silicone rubber positioning steel core according to the internal silicone rubber form and the closed mold form. The steel core is fixed on the outer mold by screws and evenly distributed around the mold.

[0071]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com