One-time forming pressure injection mold for furniture production

A technology for injection moulding and furniture, applied in the field of one-shot injection moulding, can solve the problems such as the need to improve the heating and cooling efficiency, difficulty in injection moulding of multiple products, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

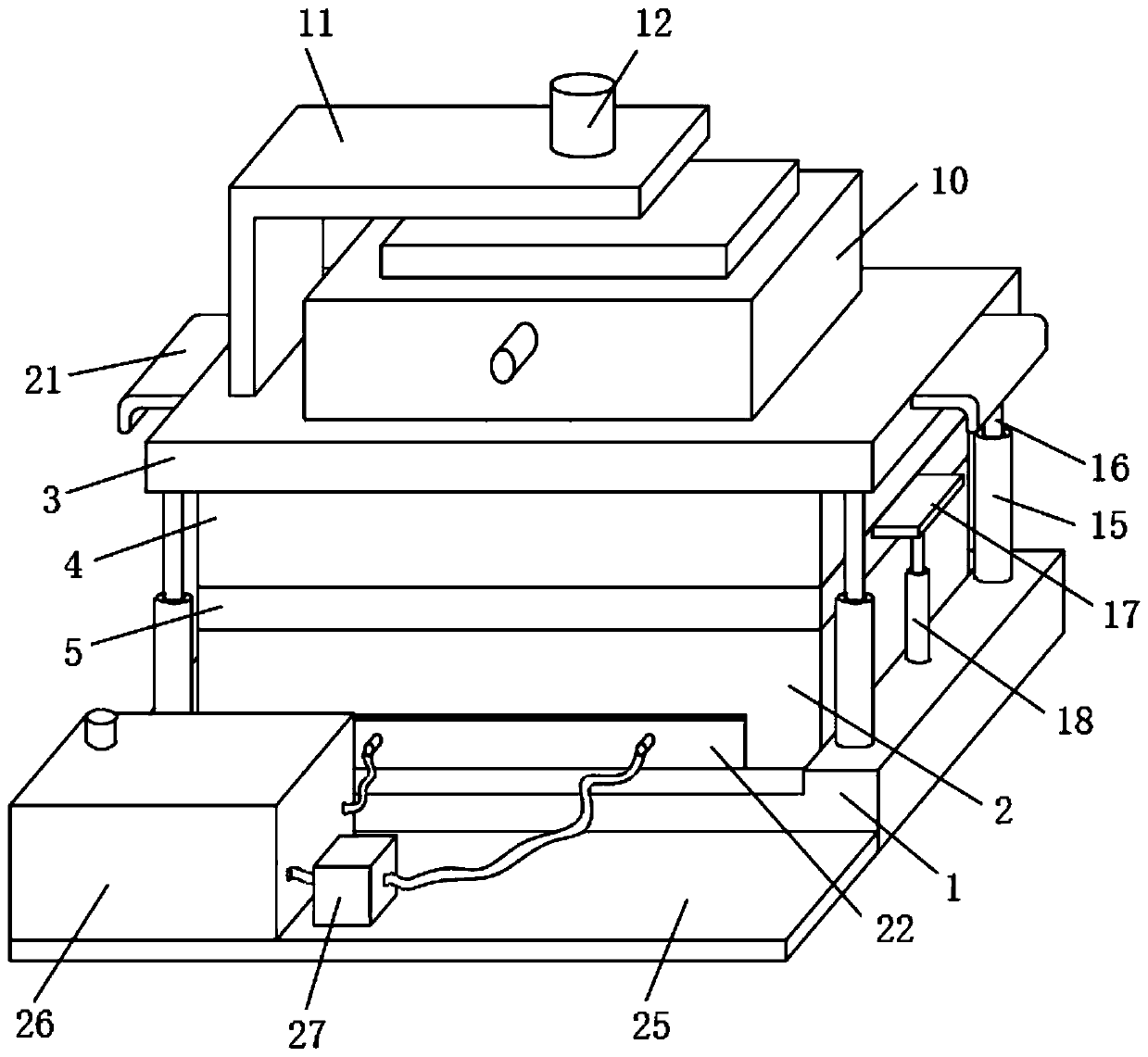

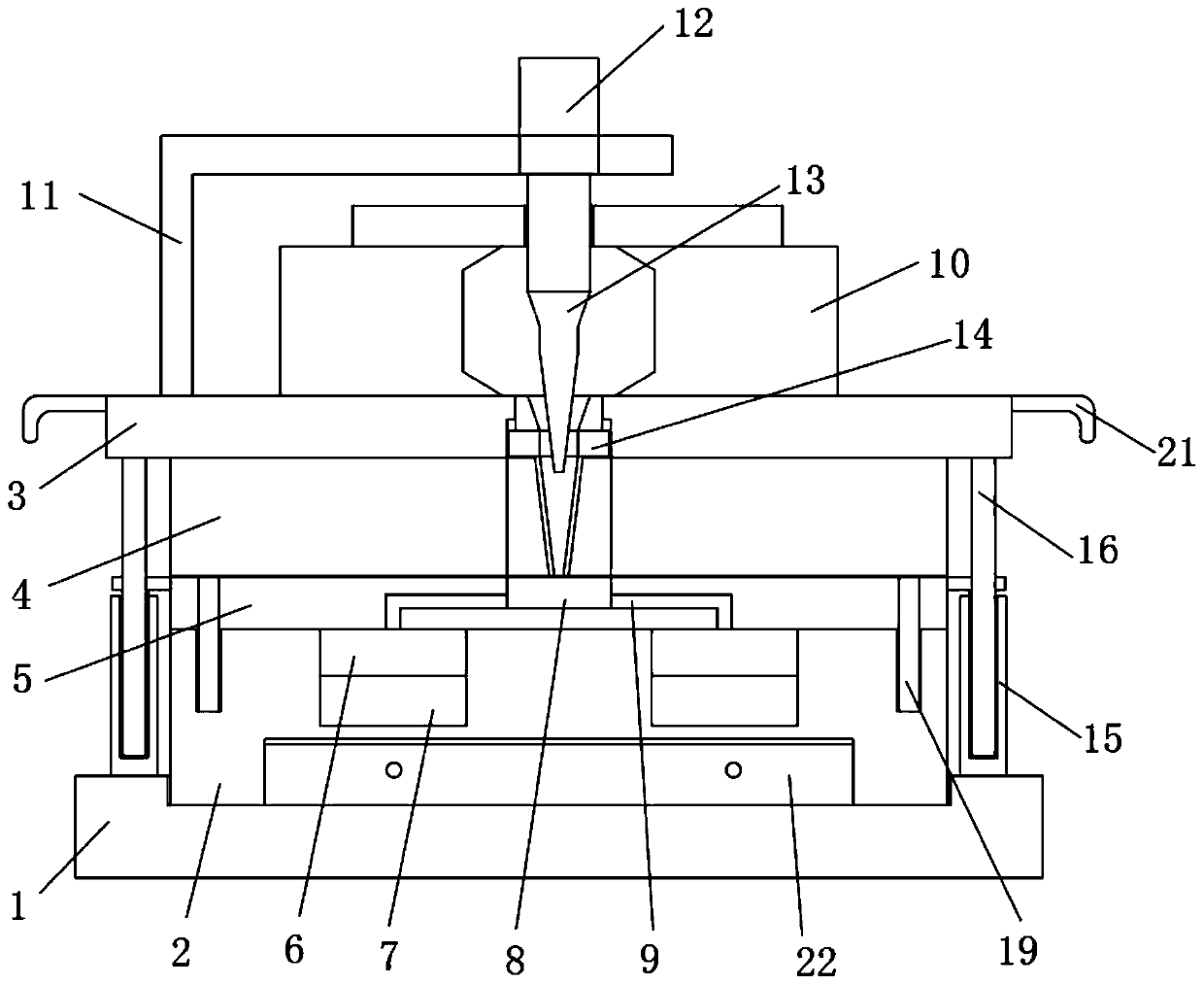

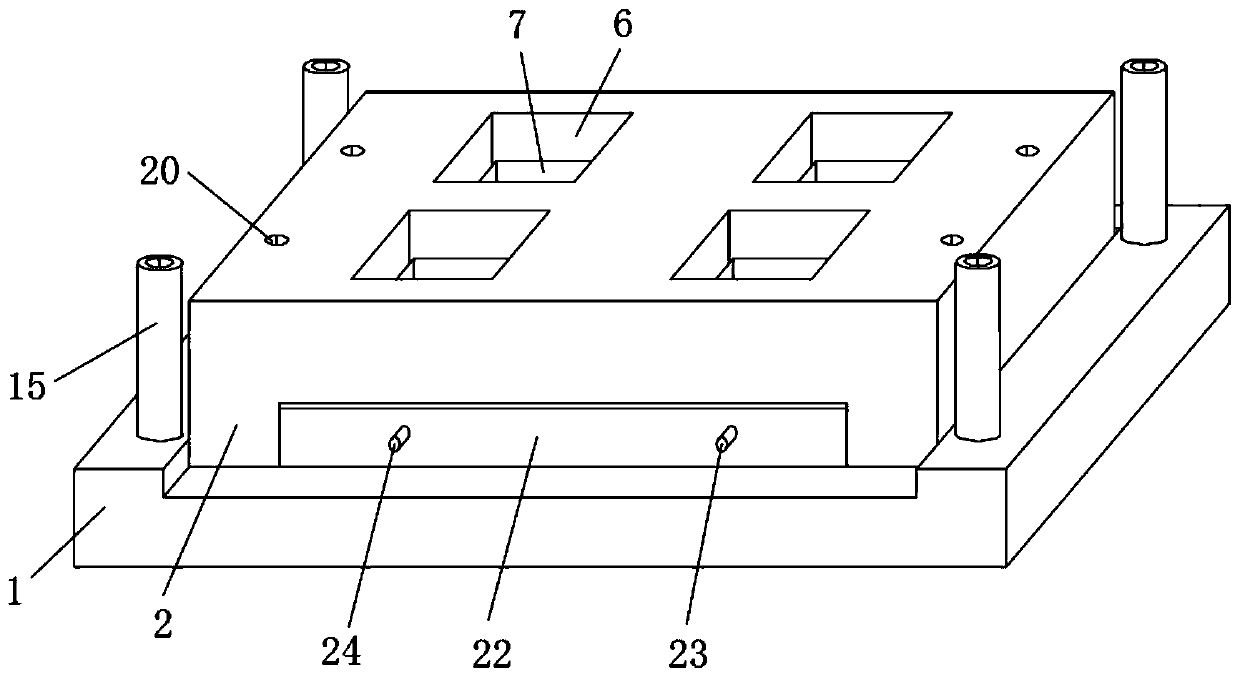

[0040] see figure 1 , a one-shot molding injection mold for furniture production, comprising a lower template 2 with a mold base 1 installed at the lower end and an upper template 4 with a sprue plate 3 installed at the upper end, the upper template 4 is located above the lower template 2, and the mold base 1 There is an installation cavity for installing the lower formwork 2 at the upper end of the upper end, and both sides of the lower end of the mold base 1 are connected to both sides of the lower end of the gate plate 3 through two guide mechanisms. The guide post 15 and the guide rod 16 fixedly connected to the lower end of the gate plate 3, the lower end of the guide rod 16 is movably inserted in the hollow guide post 15, the guide rod 16 and the hollow guide post 15 are used in conjunction to realize the injection mold closing The accuracy of mold and demoulding, and L-shaped handles 21 are fixedly connected to both sides of the gate plate 3. The outer end surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com