Cement test part curing box with uniform temperature and humidity

A curing box, temperature and humidity technology, which is applied in the field of construction cement specimen testing equipment, can solve the problems of difficult to adapt to the maintenance of cement setting time stability specimens, and the temperature and humidity of the curing box are not easy to quickly recover, and achieve uniform and stable recovery and uniform water temperature. Stable, avoid excessive cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

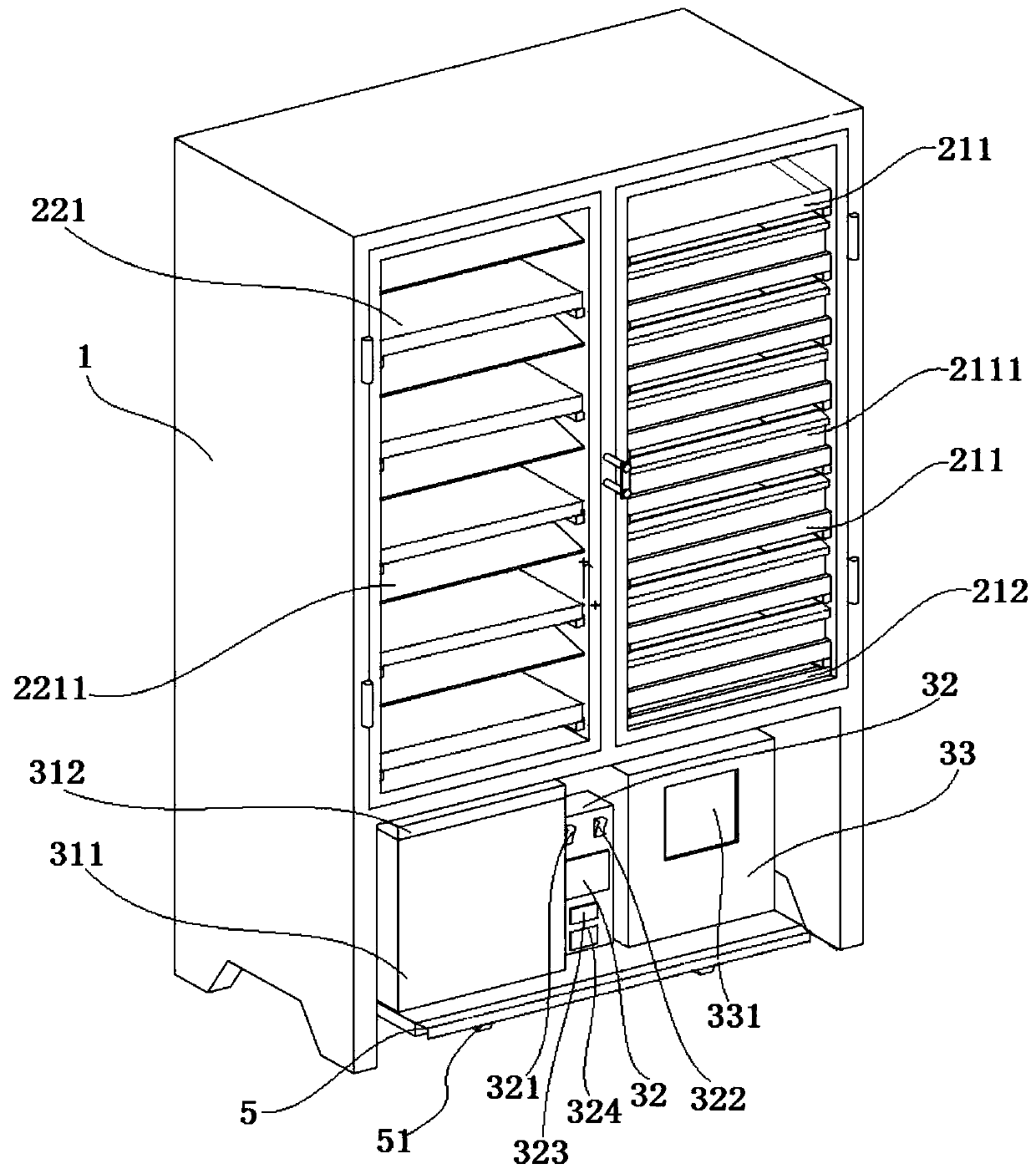

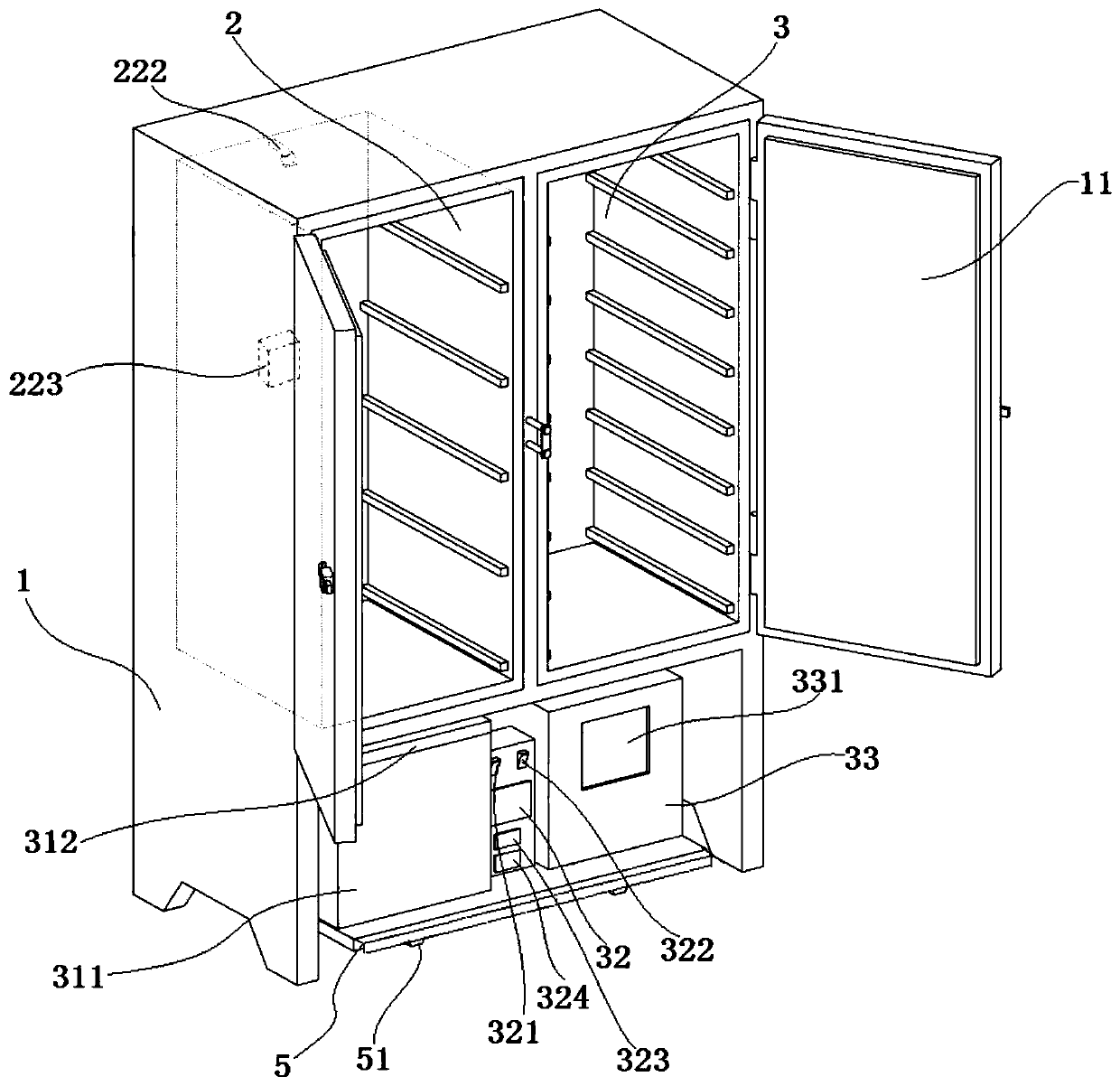

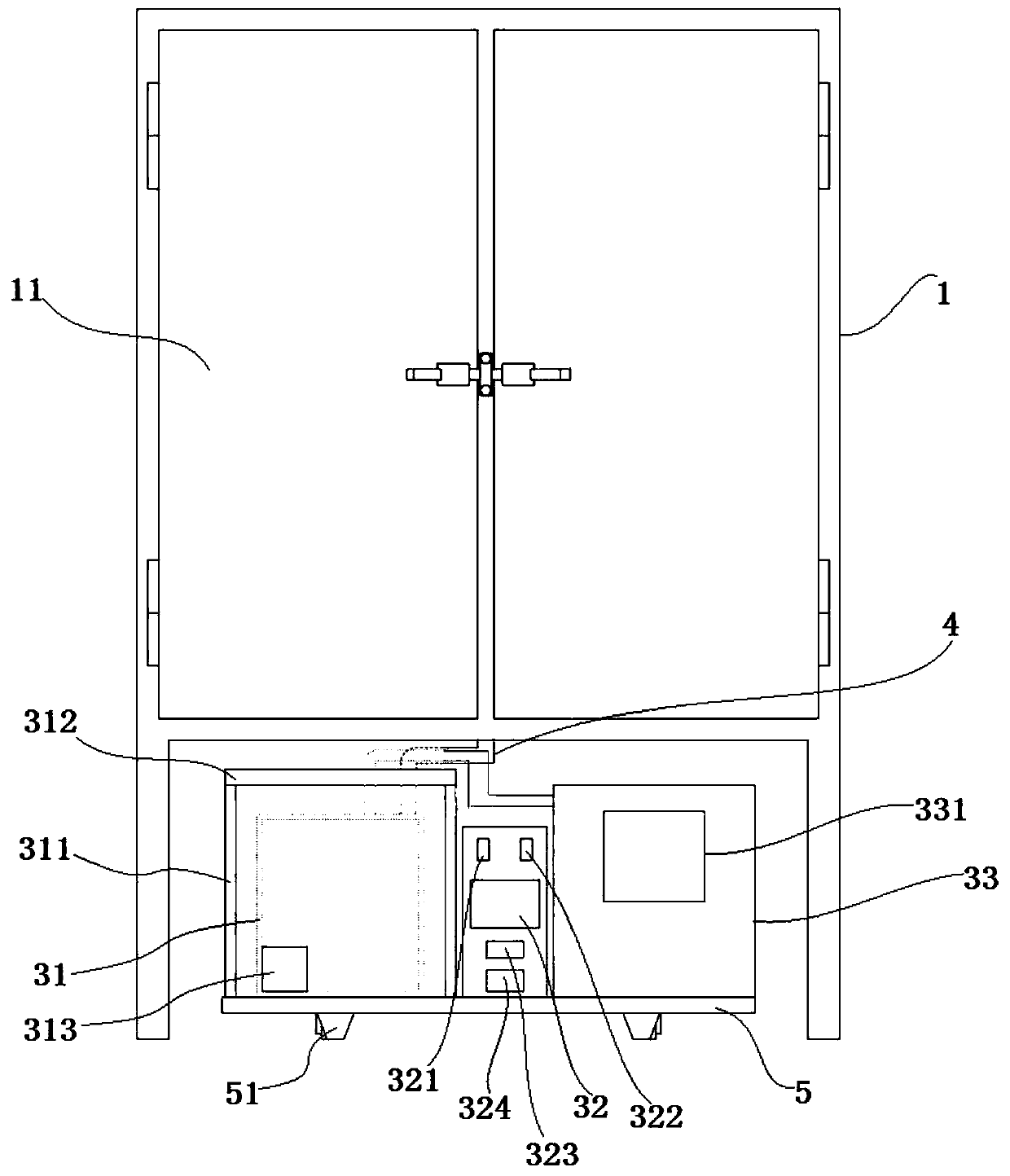

[0054] During use, turn on the power supply of the constant temperature water circulation device 3, the circulating water pump 34 is turned on, the water temperature controller 32 detects the circulating water temperature, enters the cooling adjustment mode when the temperature is high, turns on the cooling water pump 313, and the cold storage water tank 331 and the water in the constant temperature water tank 31 start Circulate until the water temperature in the constant temperature water tank 31 drops to 20°C; when the temperature is low, enter the heating adjustment mode, turn on the electric heating tube, until the water temperature in the constant temperature water tank 31 rises to 20°C.

[0055] The refrigerator 33 directly refrigerates the cold storage water tank 331 , and the cooling water pump 313 circulates the water in the cold storage water tank 331 and the constant temperature water tank 31 . When the constant temperature circulating water needs to be cooled, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com