Multi-point precision thread adjusting clamping mechanism

A technology of clamping mechanism and precision thread, which is applied in the direction of workpiece clamping devices and manufacturing tools, and can solve the problems of moving down a small amount, inconvenient operation, and moving up a small amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

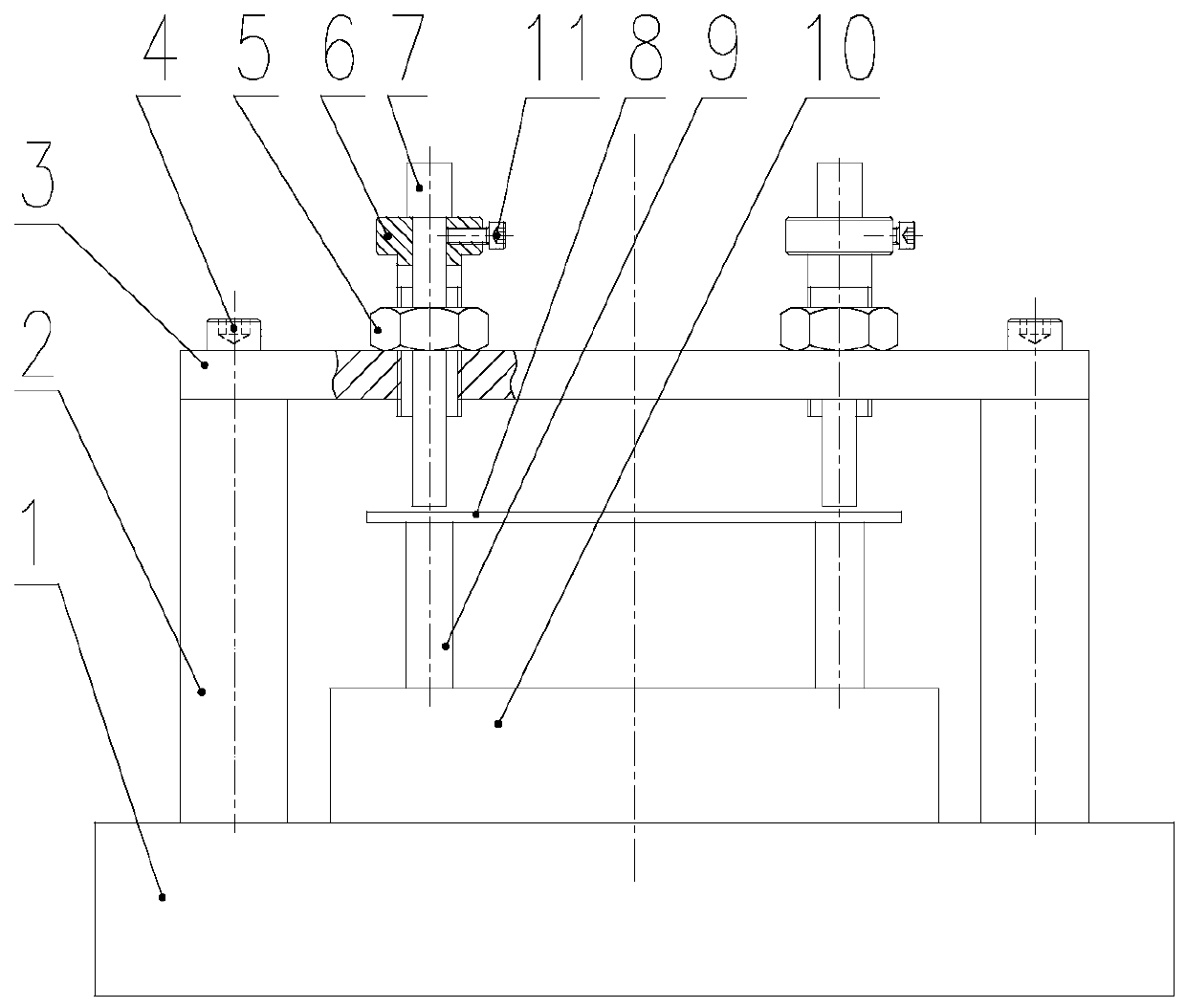

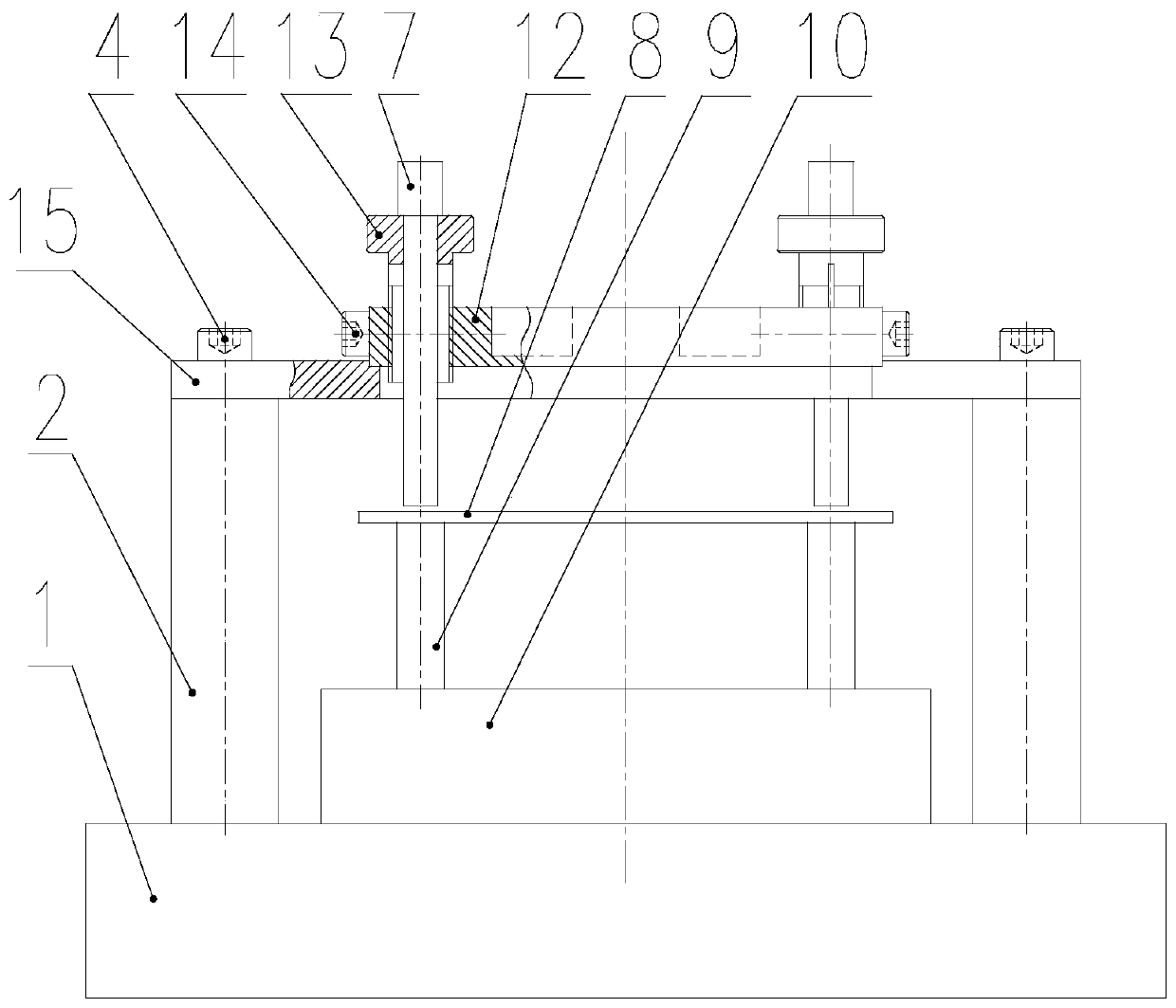

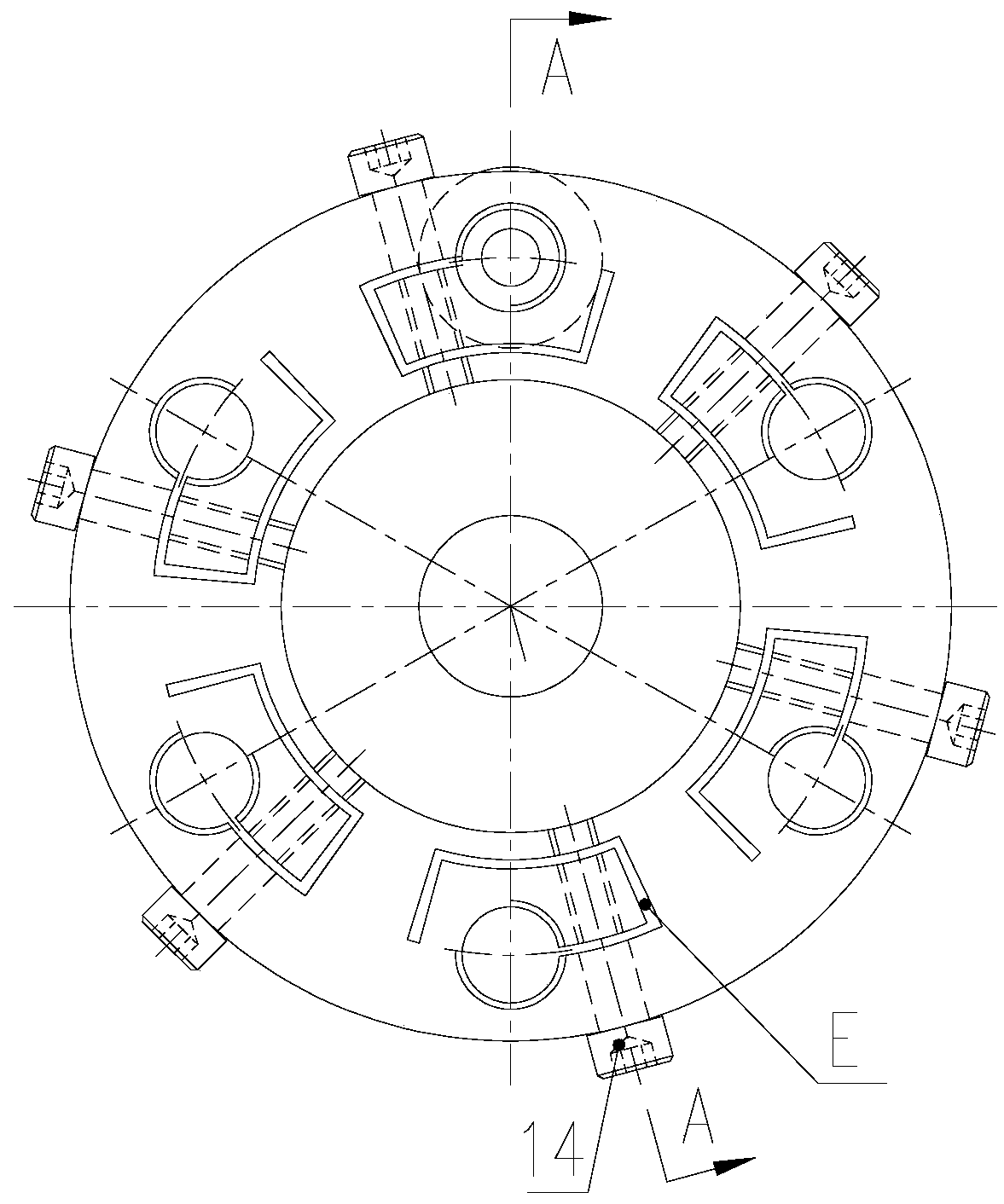

[0012] Embodiment 1, multi-point precision thread adjustment clamping mechanism, refer to figure 2 , Figure 3-1 , Figure 3-2 , Pic 4-1 , Figure 4-2 , Figure 4-3 , the detected part 8 is cemented with the displacement actuator 9, the displacement actuator 9 is fixed on the chassis 10, the chassis 10 is fixed on the optical table 1, and the multi-point mounting nut orifice plate 12 and the base plate 15 are connected together by gluing, The base plate 15 is connected with the column 2 through the screw 4 and fixed on the optical platform 1 through the column 2 . The detection sensor 7 is inserted into the hollow adjusting screw 13, and the outer circle of its matching part is in clearance fit with the inner hole of the hollow adjusting screw 13, and its upper and lower positions are positioned by steps under its own gravity, and the hollow adjusting screw 13 is screwed. In the nut holes of the nut orifice plate 12 installed at multiple points, groove lines are process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com